Positive pole material of lithium ion battery and preparation method of material

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as deterioration of electrochemical performance, deterioration of material structure stability, and reduction of material crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The invention provides a kind of preparation method of lithium-ion battery cathode material, comprises the following steps:

[0051] Mixing a phosphorus source compound, a manganese source compound, an M-containing compound, a lithium source compound, a carbon source compound and a surfactant in water to obtain a suspension, wherein M is Ti, Co, Fe, Mg, Al, Cr and Nb A sort of;

[0052] Under airtight conditions, the suspension is heated to obtain a positive electrode material precursor;

[0053] In an inert atmosphere, the positive electrode material precursor is calcined to obtain the lithium ion battery positive electrode material.

[0054] The present invention uses phosphorus source compounds, manganese source compounds, M-containing compounds, lithium source compounds, carbon source compounds and surfactants as raw materials. After mixing them, they are first heated and reacted to obtain a positive electrode material precursor; then the obtained positive electrod...

Embodiment 1

[0079] The mass concentration of 115.3g is 85% phosphoric acid, the manganese carbonate of 93.1g, the iron oxide of 15.17g, the lithium hydroxide of 46.16g, the sucrose of 40.46g and 2.7g sodium dodecylbenzene sulfonate are dispersed in 730g Prepare a suspension with a solid content of 30% in deionized water; then add the above suspension into the reactor, heat it to 200°C for 15 hours under closed conditions, and wash the obtained solid after the reaction is completed and cooled to room temperature , filtered and dried to obtain a lithium manganese phosphate precursor powder; then the obtained lithium manganese phosphate precursor powder was roasted at a high temperature for 8 hours under the protection of a nitrogen atmosphere, the roasting temperature was 500 ° C, and then cooled to room temperature to obtain a lithium ion battery positive electrode material .

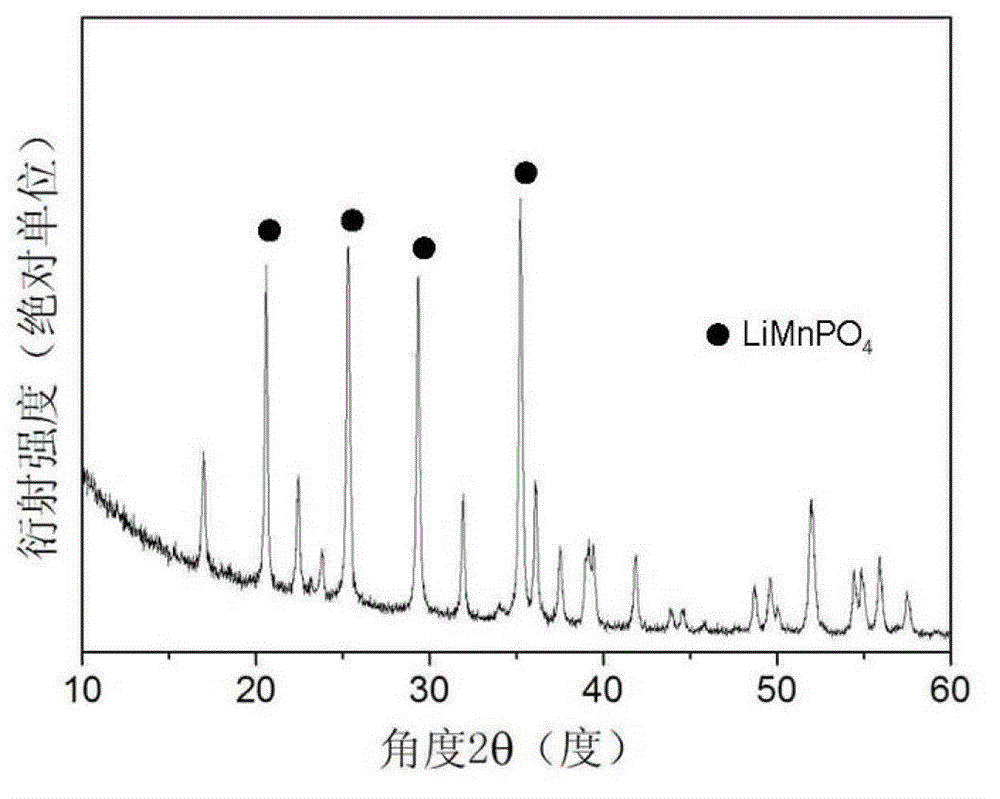

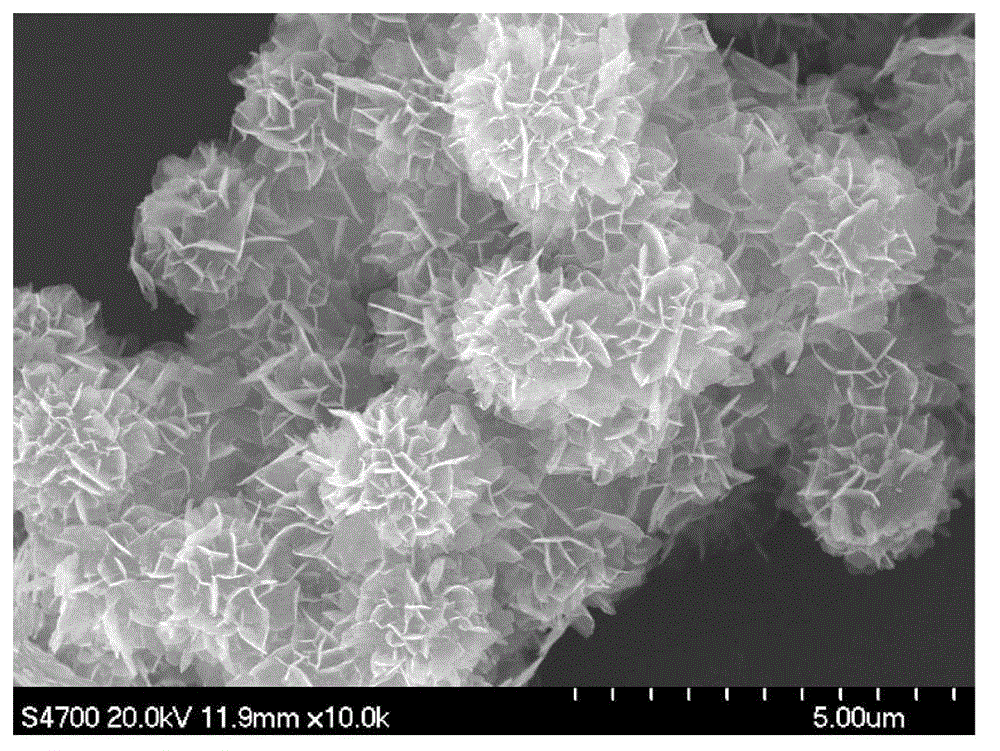

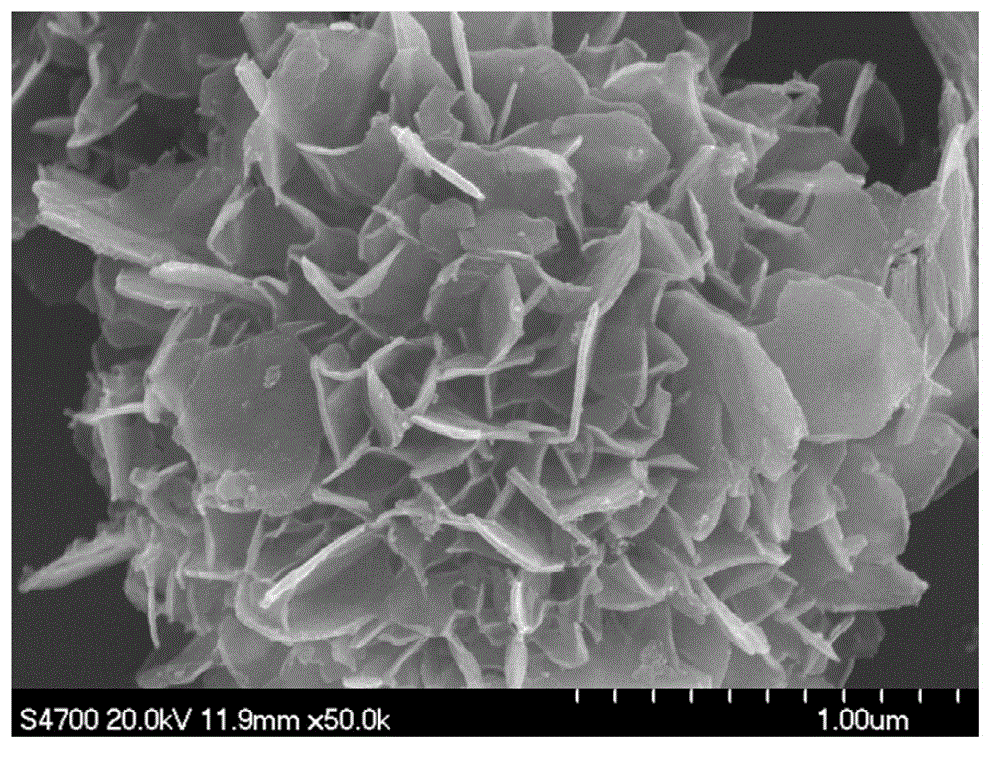

[0080] The present invention carries out X-ray diffraction analysis to the positive electrode material of lithium...

Embodiment 2

[0093] The diammonium hydrogen phosphate of 138.66g, the manganese acetate of 220.58g, the titanium dioxide of 7.98g, the lithium carbonate of 38.79g, the sucrose of 20.3g and the deionized water of 20.3g are dispersed in the deionized water of 670g, make the solid content be 40 % of the suspension; then the above suspension was added to the reaction kettle, heated to 150 ° C under airtight conditions for 10 hours of reaction, after the reaction was completed and cooled to room temperature, the obtained solid was washed, filtered and dried to obtain lithium manganese phosphate Body powder; then the obtained lithium manganese phosphate precursor powder is calcined at a high temperature for 5 hours under the protection of nitrogen atmosphere, the calcining temperature is 600° C., and then cooled to room temperature to obtain the positive electrode material of lithium ion battery.

[0094] The present invention carries out XRD analysis to the positive electrode material that obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com