Composite conductive agent, lithium ion battery pole pieces and lithium ion battery

A composite conductive agent and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of reduced cycle performance, difficulty in forming a conductive network, and increased usage, so as to enhance short-range electronic conduction, avoid high specific surface area, and increase energy density. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

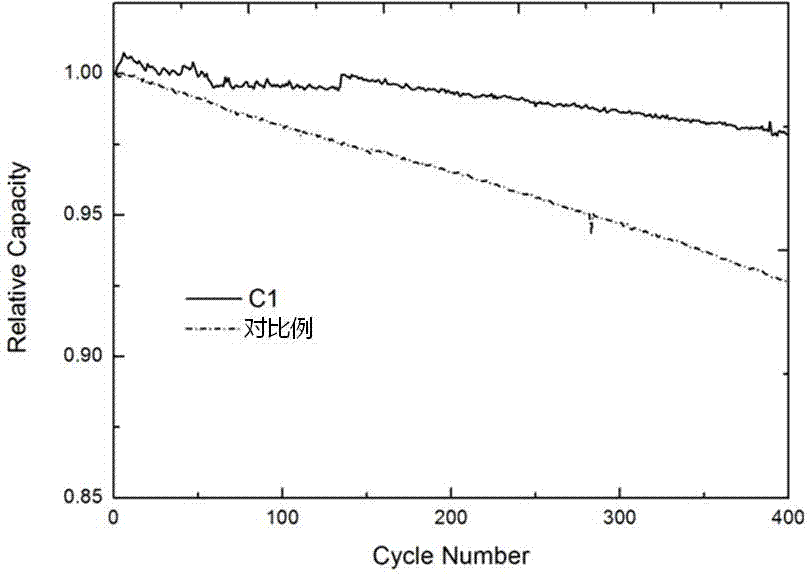

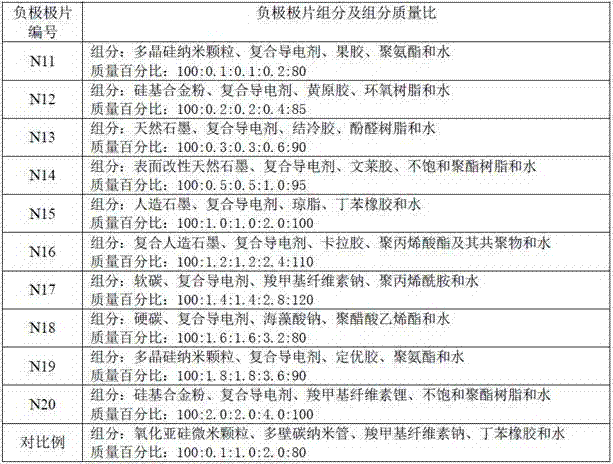

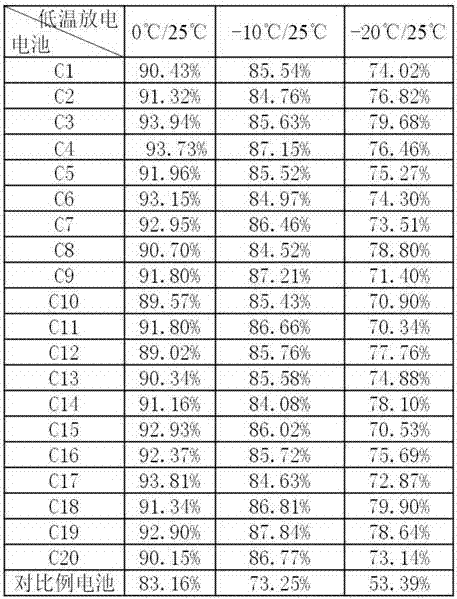

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0050] 1. Preparation of composite conductive agent

[0051] Prepare the composite conductive agent according to the components and the properties of the components in the following table:

[0052]

[0053] The preparation method of the composite conductive agent in this embodiment is: adding single-wall or few-wall carbon nanotubes, graphene nanosheets and dispersant to the diluent, the mass parts of the components added are: 100 parts of diluent, 2 parts of carbon nanotubes with or without walls, 2 parts of graphene nanosheets, 0.55 parts of a dispersant, fully dispersed; the dispersant is sodium carboxymethyl cellulose, and the diluent is N-methylpyrrolidone.

[0054] The composite conductive agent No. 3 was selected to prepare the battery pole piece in this embodiment. One of the reasons for choosing No. 3 composite conductive agent is that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com