Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of large volume expansion effect, capacity attenuation, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

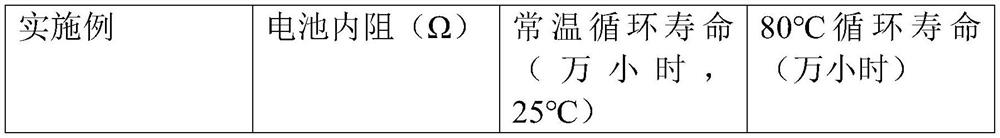

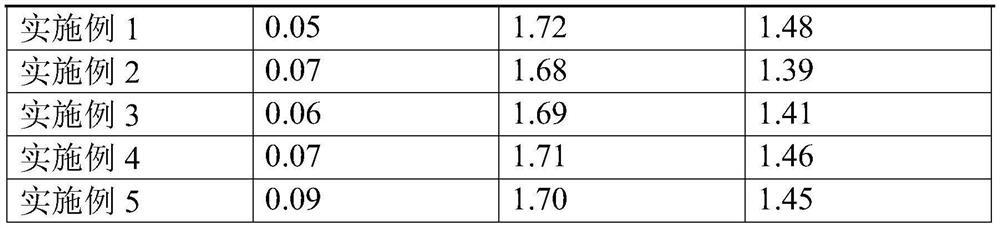

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0028] (1) Weigh molybdenum powder, silicon powder, boron powder and 2 molybdenum alloy powder, the sum of the mass fractions of the above components is 100%; the above-mentioned raw material components weighed are put into a planetary high-energy ball mill for ball milling, and an inert gas is introduced during the ball milling process to keep the ball milling tank The gas pressure is 0.2-0.5MPa;

[0029] (2) sieve the powder mixture after the above-mentioned ball milling treatment, and pass through a 300-400 mesh sieve;

[0030] Then put the powder mixture in the atmosphere resistance furnace, pass high-purity nitrogen gas to fully discharge the air, heat it to 1850-1900°C for calcination, and naturally cool the sintered product with the furnace to obtain Mo 5 SiB 2 -ZrB 2 Complex;

[0031] (3) Disperse zirconium oxychloride oct...

Embodiment 1

[0056] A preparation method for a lithium ion battery negative electrode material, comprising the following steps:

[0057] (1) Weigh molybdenum powder, silicon powder, boron powder and 2 molybdenum alloy powder, the sum of the mass fractions of the above components is 100%; put the above-mentioned weighed raw material components into a planetary high-energy ball mill for ball milling, and nitrogen gas is introduced during the ball milling process to keep the gas in the ball milling tank The pressure is 0.35MPa; the revolution speed of the planetary high-energy ball mill is 80rpm, and the rotation speed is 630pm.

[0058] Described molybdenum powder, silicon powder, boron powder and containing ZrB 2 The molar ratio of the molybdenum alloy powder is 4.2:0.8:2.0:1; wherein, the ZrB 2 The mass fraction in molybdenum alloy powder is 2.5wt%.

[0059] (2) sieve the powder mixture after the above-mentioned ball milling process, and pass through a 400 mesh sieve;

[0060] Then put...

Embodiment 2

[0072]This embodiment is basically the same as the preparation method of lithium ion battery negative electrode material in embodiment 1, the difference is,

[0073] Described molybdenum powder, silicon powder, boron powder and containing ZrB 2 The molar ratio of the molybdenum alloy powder is 3.5:0.6:1.5:1; wherein, the ZrB 2 The mass fraction in molybdenum alloy powder is 2.5wt%;

[0074] With the rest unchanged, a lithium ion battery was prepared according to the preparation method of the positive electrode, the negative electrode and the lithium ion battery of the lithium ion battery in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com