Micron-opened cage-like defect mno@ni material and its preparation method and application

A technology of defect and cage, which is applied in the field of micro-opening cage-like defect MnO@Ni material and its preparation, can solve the problems of low tap density, poor rate performance, low volume capacity, etc., to suppress crushing and offset volume change , the effect of expanding the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the micron-opened cage-like defect MnO@Ni material provided by the present invention comprises the following steps:

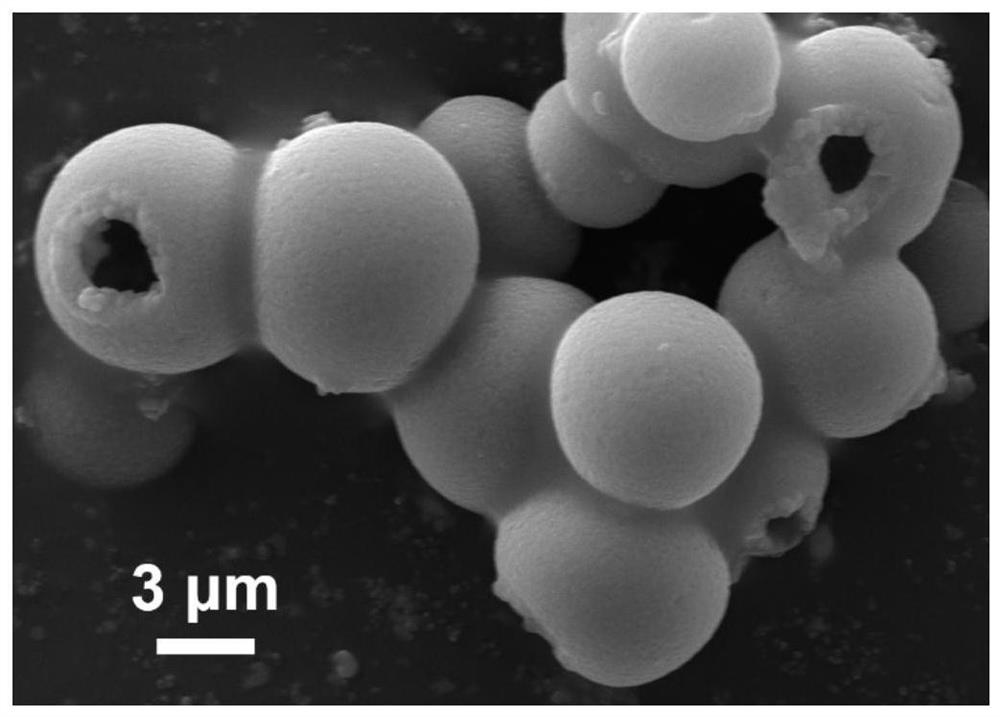

[0045] (1) prepare a mixed solution of 1,3,5-benzenetricarboxylic acid, nickel nitrate and manganese chloride, transfer the mixed solution into a reaction vessel, perform hydrothermal reaction at 150° C. for 36 hours, and then separate, wash and The precursors of Ni-Mn-MOFs open microcages were obtained by drying and collection.

[0046] Specifically, the mixed solution is prepared as follows: 1,3,5-benzenetricarboxylic acid, nickel nitrate hexahydrate and manganese chloride are dispersed in a mixed solvent of distilled water and dimethylformamide by ultrasonic to obtain a clear mixture.

[0047] More preferably, the mass ratio of 1,3,5-benzenetricarboxylic acid, nickel nitrate hexahydrate and manganese chloride is 53:109:74. The volume ratio of the distilled water to dimethylformamide is 1:1.

[0048] In this step, more prefer...

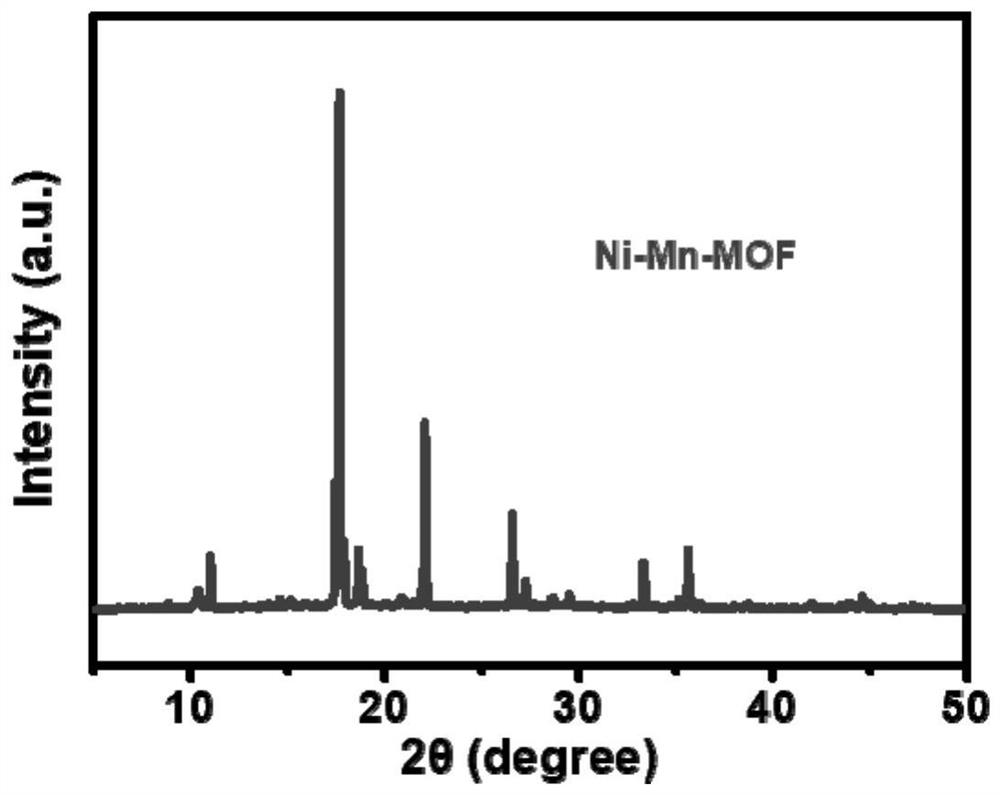

Embodiment 1

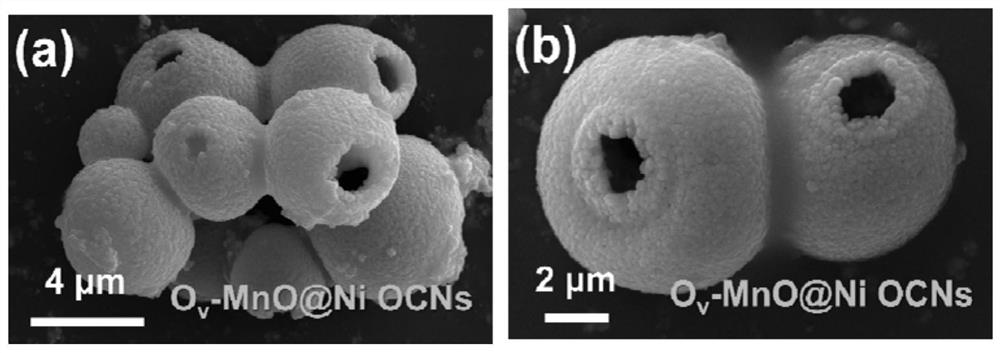

[0053] First, 0.53 g of 1,3,5-benzenetricarboxylic acid, 1.09 g of nickel nitrate hexahydrate and 0.74 g of manganese chloride were dispersed in 80 mL of a mixed solvent of distilled water and dimethylformamide (distilled water and dimethylformamide) by ultrasonication. The volume ratio of the amide is 1:1) for dispersion to obtain a clear solution. Then, the prepared clear solution was sealed in a 100 mL stainless steel autoclave and hydrothermally reacted at 150 °C for 36 h. After naturally cooling to room temperature, the precursors obtained by the reaction were separated, then washed with distilled water and ethanol for 3 times, and then vacuum-dried at 70 °C overnight to collect the Ni-Mn-MOFs open-ended microcaged precursors. Then, the as-prepared Ni-Mn-MOFs open-ended microcage precursor was heated at 2 °C for min. -1 The heating rate was increased to 700 °C, and calcined under nitrogen for 2 h to obtain a MnO@Ni material with micron open-pore cage-like defects, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com