Plastic bottle with flexible base section

A technology of plastic container and mouth section, applied in the field filled with liquid medium (such as cold medium, it can solve the problems of the convenience of labeling, the impact of production cost, the aesthetics of multiple bottles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

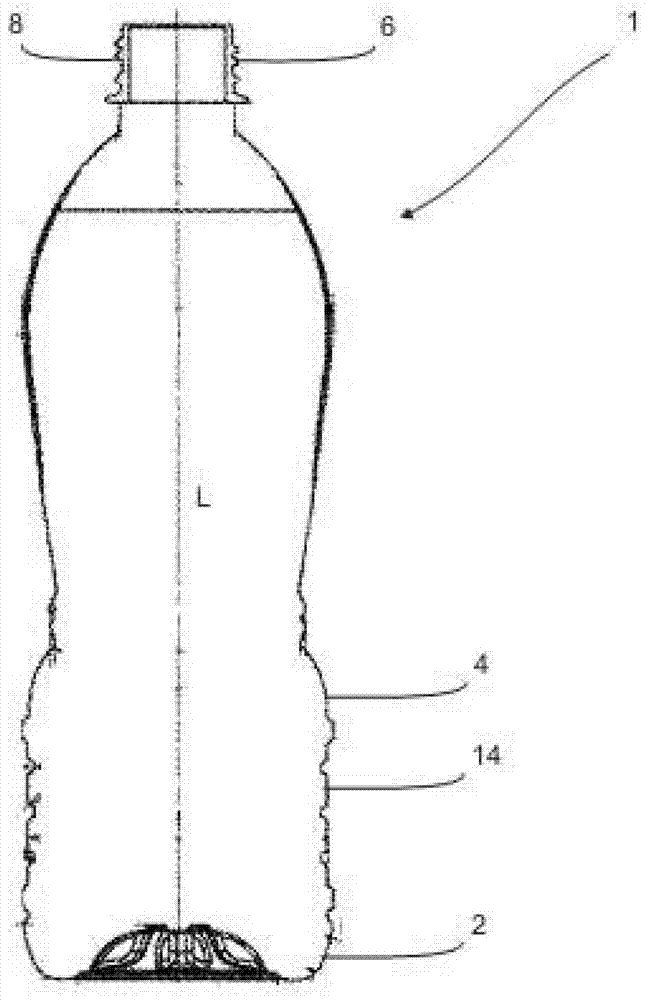

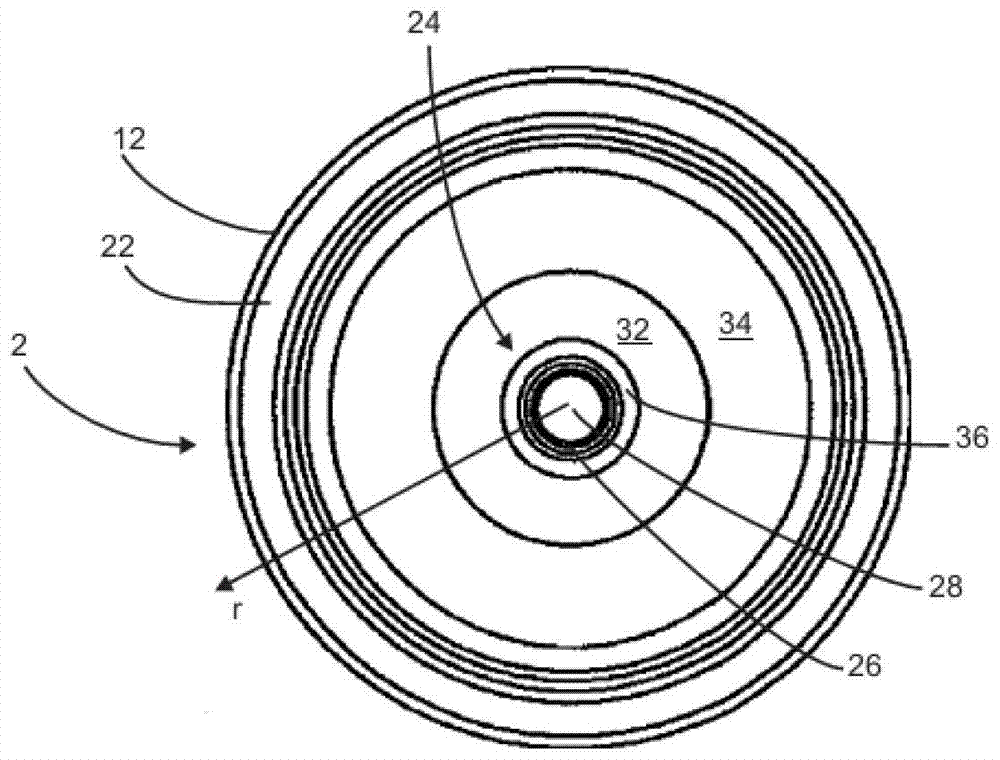

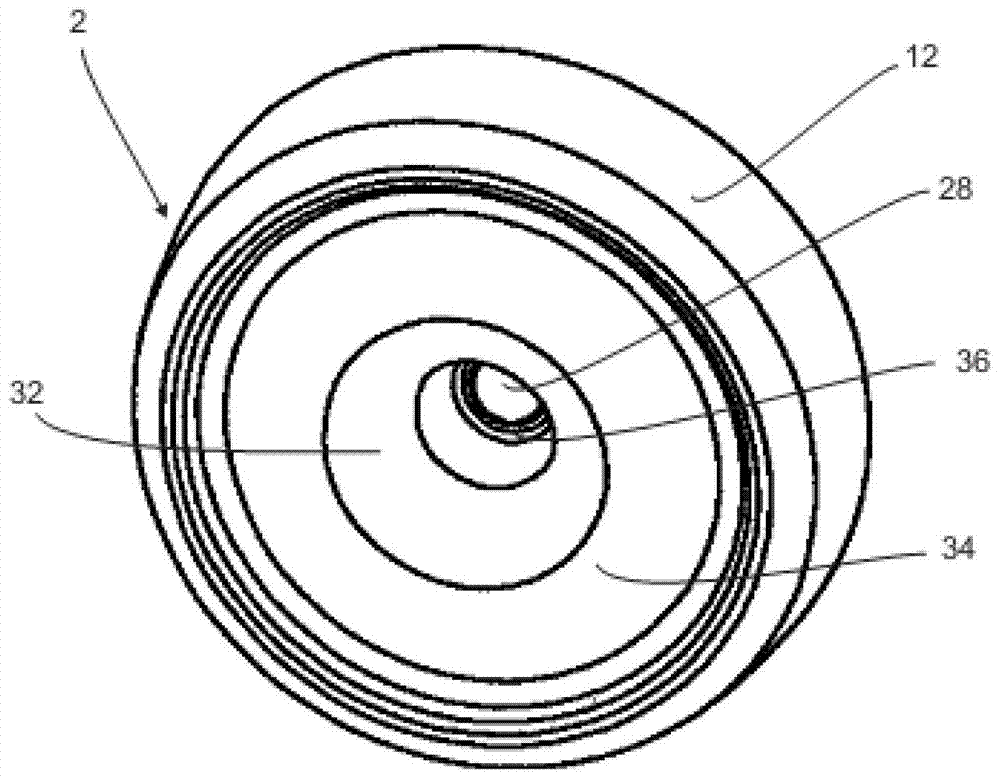

[0068] figure 1 A side view of a plastic bottle 1 is shown in . The plastic bottle 1 comprises a bottom section 2 , a middle section 4 with a peripheral wall 14 and a mouth section 6 . The container can stand on the bottom section 2, the middle section 4 is connected to the bottom section 2 and is arranged next to the bottom section in the longitudinal direction L of the container 1, the mouth section 6 is connected to the middle section 4 and is arranged in the longitudinal direction L of the container 1 This is followed by the midsection setting. It will be appreciated that, for example, the middle section 4 may be divided into different subsections. figure 1 The container shown in preferably comprises a circular cross-section (in a plane) perpendicular to the longitudinal direction of the container. The midsection may include stiffening elements or other figure 1 The shape shown in . This mouth section 6 comprises an external thread 8 to which a cap (not shown) can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com