High-compaction-density lithium iron phosphate and preparation method thereof

A technology of lithium iron phosphate and iron phosphate, which is applied in the field of electrode material synthesis, can solve the problems of reducing equipment production capacity, increasing manufacturing costs, and cumbersome processes, and achieves the effects of low cost, high specific capacity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) Select iron phosphate A with a particle size of 3 μm and iron phosphate B with a particle size of 0.1 μm, and mix iron phosphate A and B according to a mass ratio of 3:7 to obtain mixed iron phosphate C;

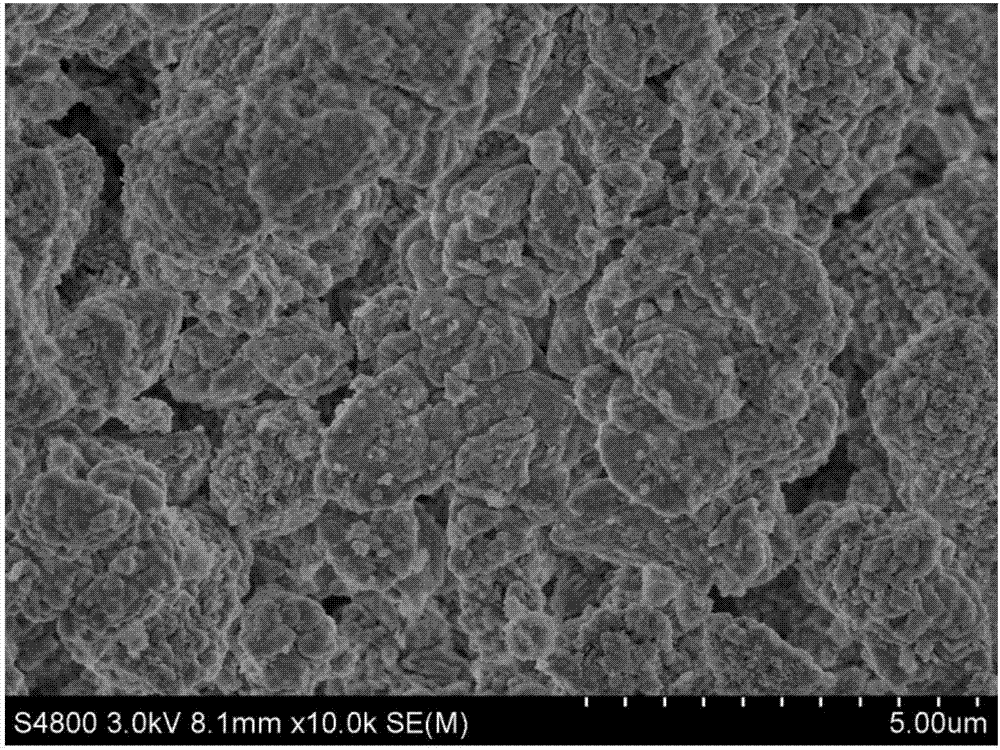

[0066] Wherein, the scanning electron microscope (scanning electronmicroscope, SEM) figure of the iron phosphate A with the primary particle size of 3 μm is as attached figure 1 As shown, from the electron microscope picture, the primary particle size of the material is about 3 μm;

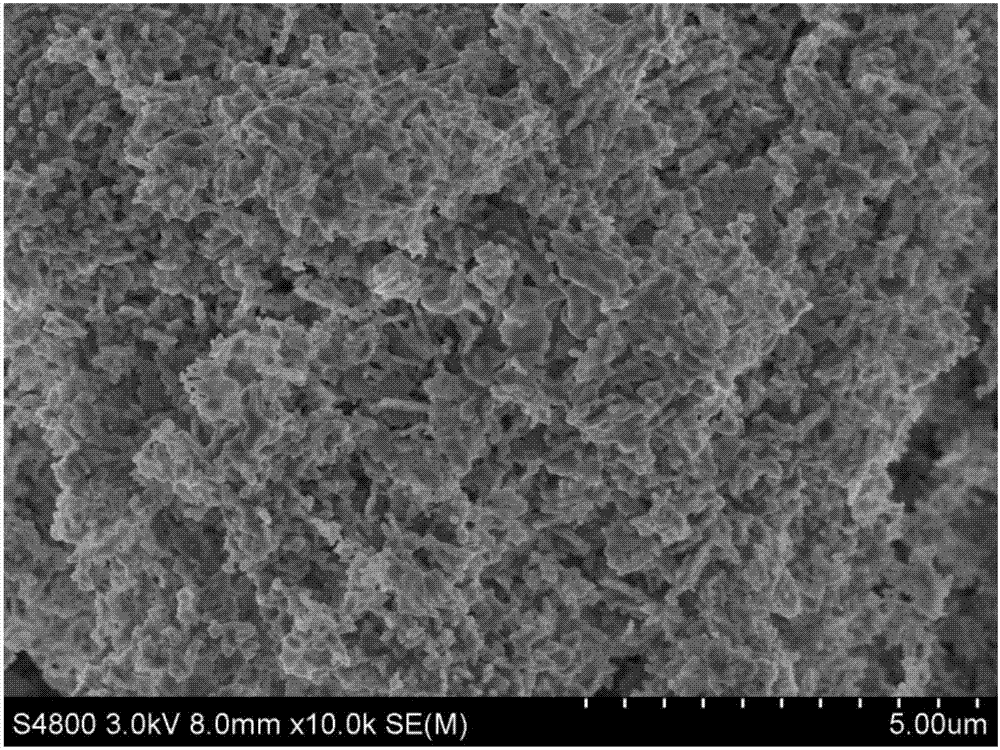

[0067] The SEM image of the iron phosphate B with a primary particle size of 0.1 μm is as attached figure 2 As shown, from the electron microscope picture, the primary particle size of the material is about 0.1 μm;

[0068] (2) Lithium carbonate and mixed iron phosphate C are mixed according to a molar ratio of 1:1, and glucose that accounts for 15% of the weight of the lithium iron phosphate precursor is added for mixing. Ethanol) 50% of total mass adds ethanol and grinds, takes o...

Embodiment 2

[0072] (1) Select iron phosphate A with a particle size of 1 μm and iron phosphate B with a particle size of 0.05 μm, and mix iron phosphate A and B according to a mass ratio of 1:9 to obtain mixed iron phosphate C;

[0073] (2) Lithium acetate, mixed iron phosphate C, and manganese acetate are mixed according to a molar ratio of 1:1:0.01, and citric acid accounting for 1% of the weight of the lithium iron phosphate precursor is added for mixing, according to the materials (lithium acetate, mixed phosphoric acid 50% of the total mass of iron C, manganese acetate, citric acid and ethanol) plus ethanol for grinding, take out the slurry after 2h, and test the slurry particle size D 50 =0.95 μm, dry the slurry at 80°C to obtain lithium iron phosphate precursor powder;

[0074] (3) Put the dried powder in N 2 Under the atmosphere, the temperature is raised at a heating rate of 5°C / min, and the temperature reaches 650°C for 15 hours to obtain sintered lithium iron phosphate, and th...

Embodiment 3

[0076] (1) Select iron phosphate A with a primary particle size of 0.6 μm, and iron phosphate B with a primary particle size of 0.2 μm, and mix iron phosphate A and B according to a mass ratio of 5:5 to obtain mixed iron phosphate C;

[0077] (2) Lithium hydroxide, mixed iron phosphate C, and magnesium oxide are mixed according to a molar ratio of 1:1:0.025, and sucrose with 8% of the weight of the precursor is added for mixing, according to the materials (lithium hydroxide, mixed iron phosphate C, 50% of the total mass of magnesium oxide, sucrose and ethanol) is added with ethanol to grind, take out the slurry after 5h, and test the slurry particle size D 50 =0.49 μm, dry the slurry at 80°C to obtain lithium iron phosphate precursor powder;

[0078] (3) Put the dried powder in N 2 Under the atmosphere, the temperature is raised at a heating rate of 2°C / min, and the temperature reaches 800°C for 6 hours to obtain sintered lithium iron phosphate, and the sintered lithium iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com