Preparation method of carbon-graphite composite material

A composite material, carbon-graphite technology, applied in the field of carbon-graphite composite material preparation, can solve the problems of low flexural and impact-resistant mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

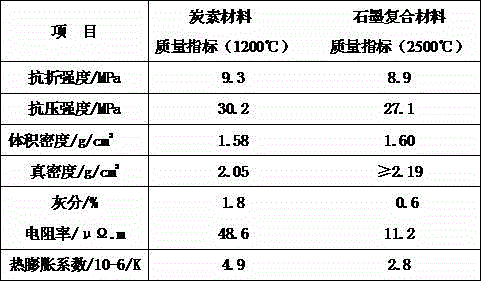

Embodiment 1

[0025] This example serves as a comparative example without adding chopped carbon fibers.

[0026] The ingredients are: ≤1mm microcrystalline graphite 5%, ≤0.075mm calcined petroleum coke 28%, 1~4mm calcined petroleum coke 15%, 4~l0mm electric calcined anthracite 10%, 10-16mm electric calcined anthracite 5%, 10-16mm Calcined pitch coke 15%, acetylene carbon black 2%, coal tar pitch 20%. Plus 1% T300PAN chopped carbon fiber (diameter 12μm, length 10mm).

[0027] (1) Ingredients and kneading, first add carbon black, natural graphite, calcined petroleum coke powder, calcined petroleum coke, electric calcined anthracite and calcined pitch coke into the kneader, the dry mixing time is 35 minutes, and the dry mixing temperature is 120°C; When the dry mixing temperature reaches the set time and temperature, add coal tar pitch at 175°C for wet mixing, the wet mixing time is 30 minutes, and the kneading temperature is 160°C to form a composite plastic body;

[0028] (2) Molding, the ...

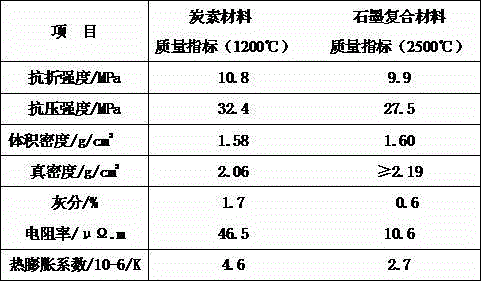

Embodiment 2

[0039] The ingredients are: ≤1mm microcrystalline graphite 5%, ≤0.075mm calcined petroleum coke 28%, 1~4mm calcined petroleum coke 15%, 4~l0mm electric calcined anthracite 10%, 10-16mm electric calcined anthracite 5%, 10-16mm Calcined pitch coke 15%, acetylene carbon black 2%, coal tar pitch 20%. Plus 1% T300PAN chopped carbon fiber (diameter 12μm, length 10mm).

[0040] (1) Ingredients and kneading, first add carbon black, natural graphite, calcined petroleum coke powder, calcined petroleum coke, electric calcined anthracite and calcined pitch coke into the kneader, and then add chopped carbon fiber for dry mixing after an interval of 5-6 minutes , the dry mixing time is 35 minutes, and the dry mixing temperature is 120°C; when the dry mixing temperature reaches the set time and temperature, add coal tar pitch at 175°C for wet mixing, the wet mixing time is 30 minutes, and the kneading temperature is 160°C , forming a composite plastic body;

[0041] (2) Molding, the compos...

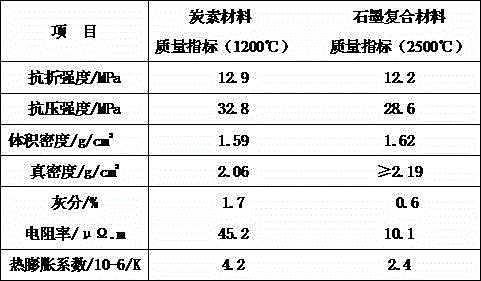

Embodiment 3

[0052] Using the same ingredients as in Example 2, plus 2% T300PAN chopped carbon fiber (diameter 12 μm, length 10 mm), the process is the same as in Example 1, and the measured performance indicators of the sample are shown in Table 3.

[0053] Table 3 The carbon material and graphite composite material quality index that embodiment 3 makes

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com