Nano carbon lubricating additive

A technology of lubricating additives and nano-carbon materials, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of lubricating performance and friction coefficient reduction that have not been seen yet, and achieve the reduction of friction coefficient, surface wear condition improvement and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

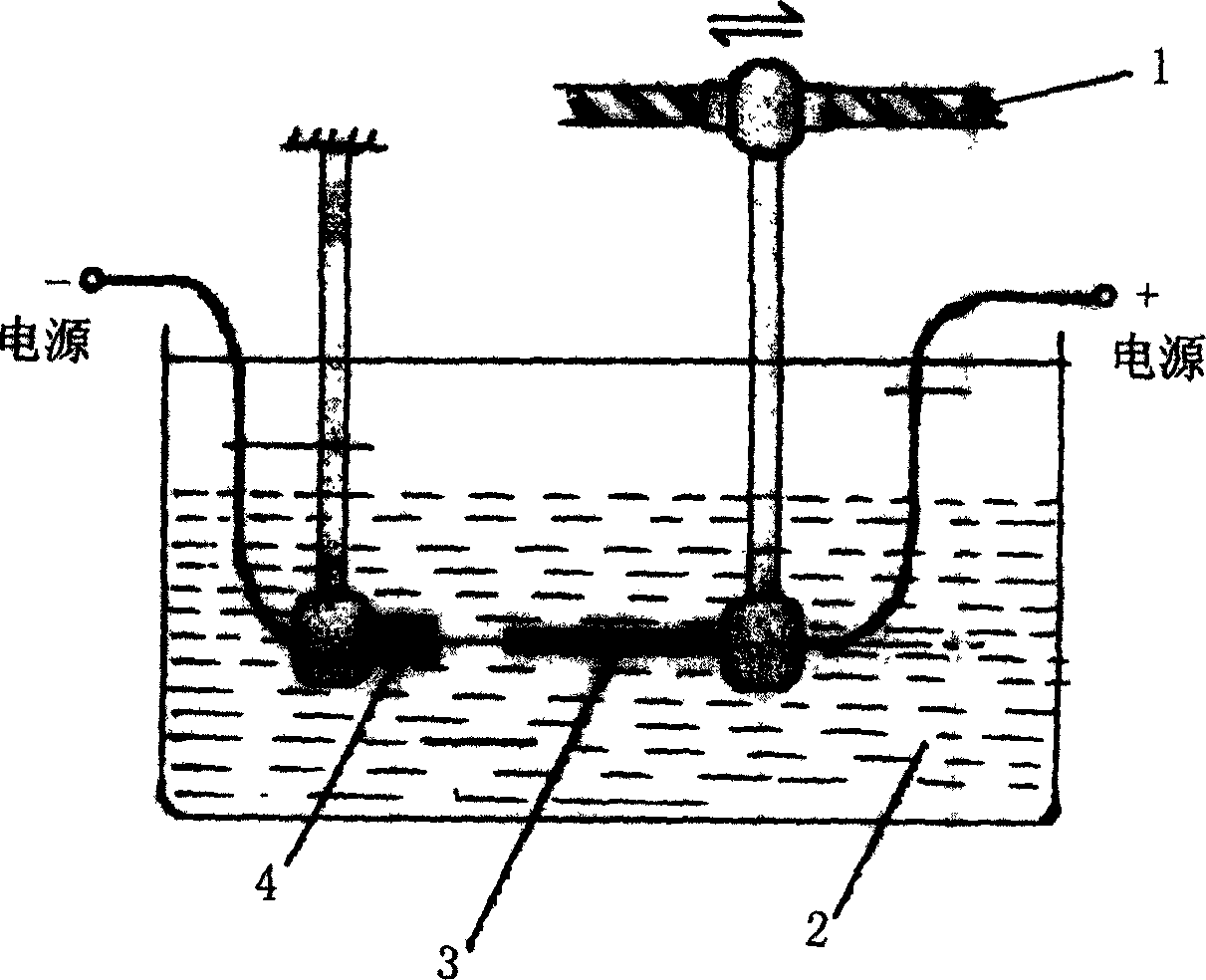

[0015] (1) The positive output terminal of the power supply of the arc discharge device is connected with the graphite anode 3, the negative output terminal of the power supply is connected with the graphite cathode 4, and put into deionized water 2; the graphite anode 3 is also fed with the graphite electrode Device 1 connection (eg figure 1 shown);

[0016] (2) Set the output parameters of the power supply: the output current density is: 1~2A / mm 2 , Voltage: 16-20V. ;

[0017] (3) Start the power supply, start the graphite electrode feeding device, and use an automatic adjustment device to automatically adjust the feeding speed to keep the arc stable;

[0018] (4) Collect and purify carbonaceous nanosphere products: collect carbonaceous nanospheres by filtration, dehydrate by centrifugation or drying;

[0019] (5) Surface grinding treatment: grinding the nanospheres for 0.5-1 hour;

[0020] (6) Add the collected carbonaceous nanospheres into the lubricating oil at a rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com