Grading and separating method for protecting crystalline graphite flakes

A crystalline graphite and quality separation technology, applied in the directions of graphite, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of insufficient application, and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

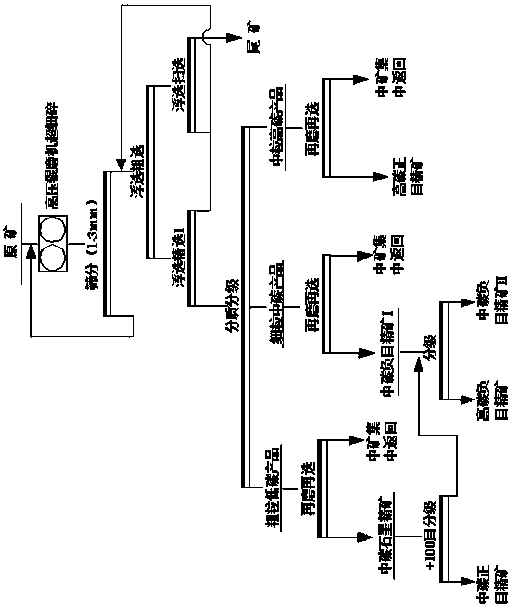

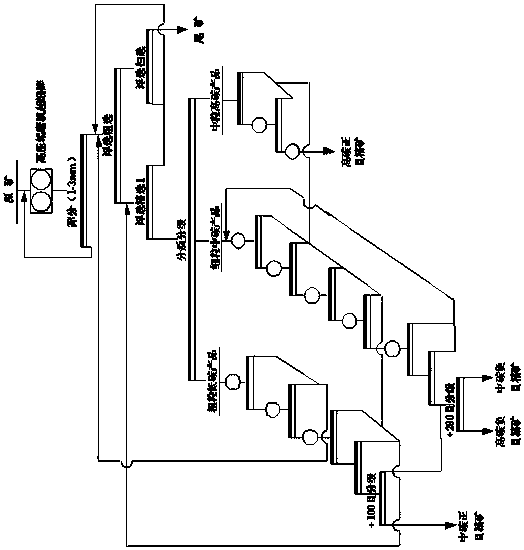

Image

Examples

Embodiment

[0031] Example: The raw ore used is crystalline graphite ore in the Alashan area of Inner Mongolia. The fixed carbon content of the raw ore is about 4.7%. The gangue minerals mainly include quartz (mineral content 30%-35%) and mica (mineral content 15%-20%) , Feldspar (mineral content 25% to 35%), also contains a small amount of carbonate minerals, hornblende, chlorite and pyrite. Graphite crystals are in the form of flakes and scales, and there are also dense massive aggregates arranged in a directional arrangement. After closed-circuit crushing in a high-pressure roller mill, the sieve hole size is controlled to 1.5 mm. The results of particle size and fixed carbon content distribution are shown in Table 1.

[0032] It can be seen from the results in Table 1 that in the finely crushed products of the high pressure roller mill, the yield rate of +100 mesh size fraction is 54.90%, and the fixed carbon distribution rate is 59.43%.

[0033] Table 1 (1.5mm raw ore particle siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com