Measuring method of remoteness grain based on laser feedback effect

A laser feedback and fine particle technology, which is applied to devices using optical methods, devices using electrical/magnetic methods, measuring devices, etc., can solve problems such as measurement difficulty, and achieve strong repeatability, reliable data, and simple implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0021] A method for measuring fine particles based on laser feedback effect: its specific steps are:

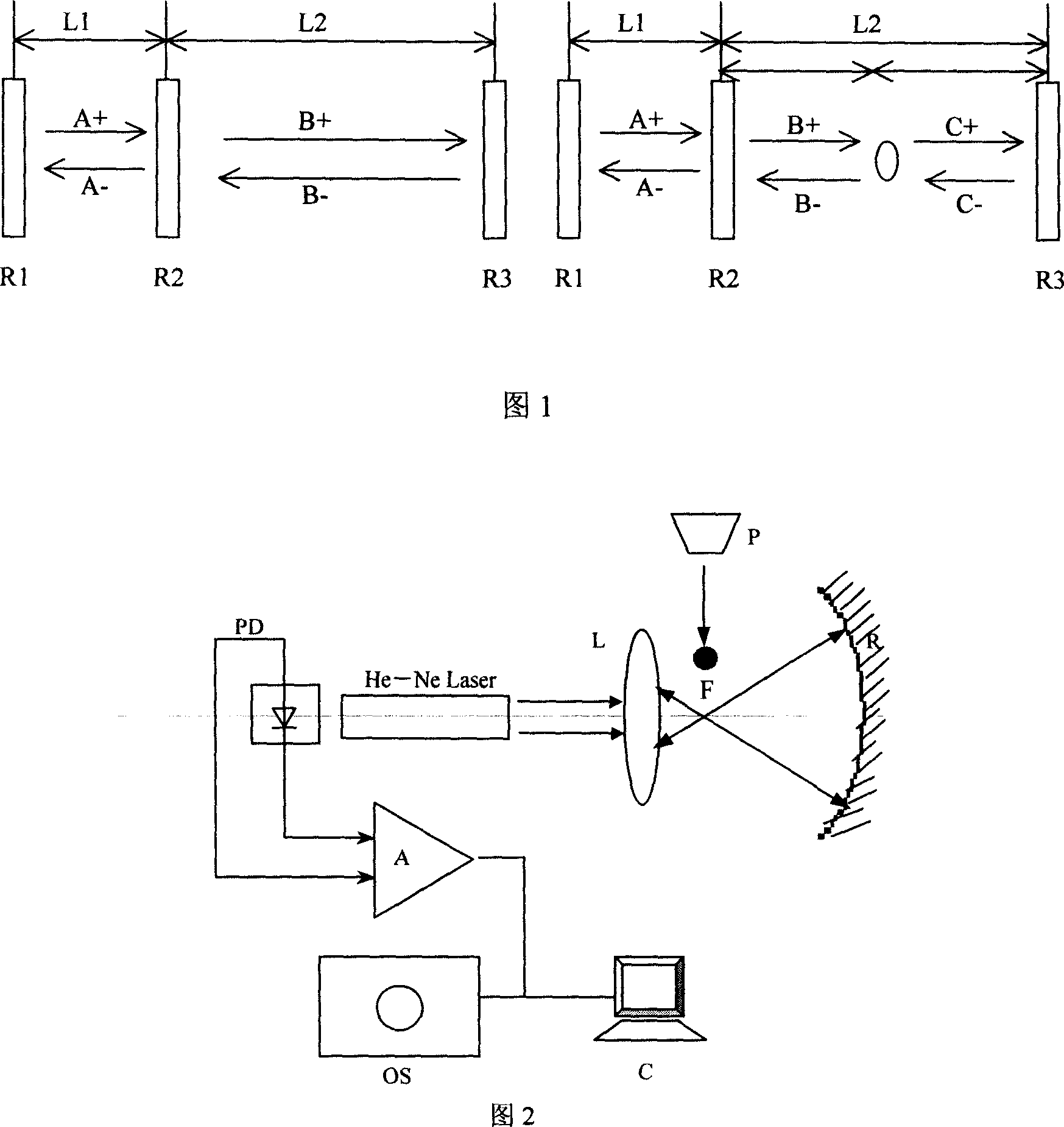

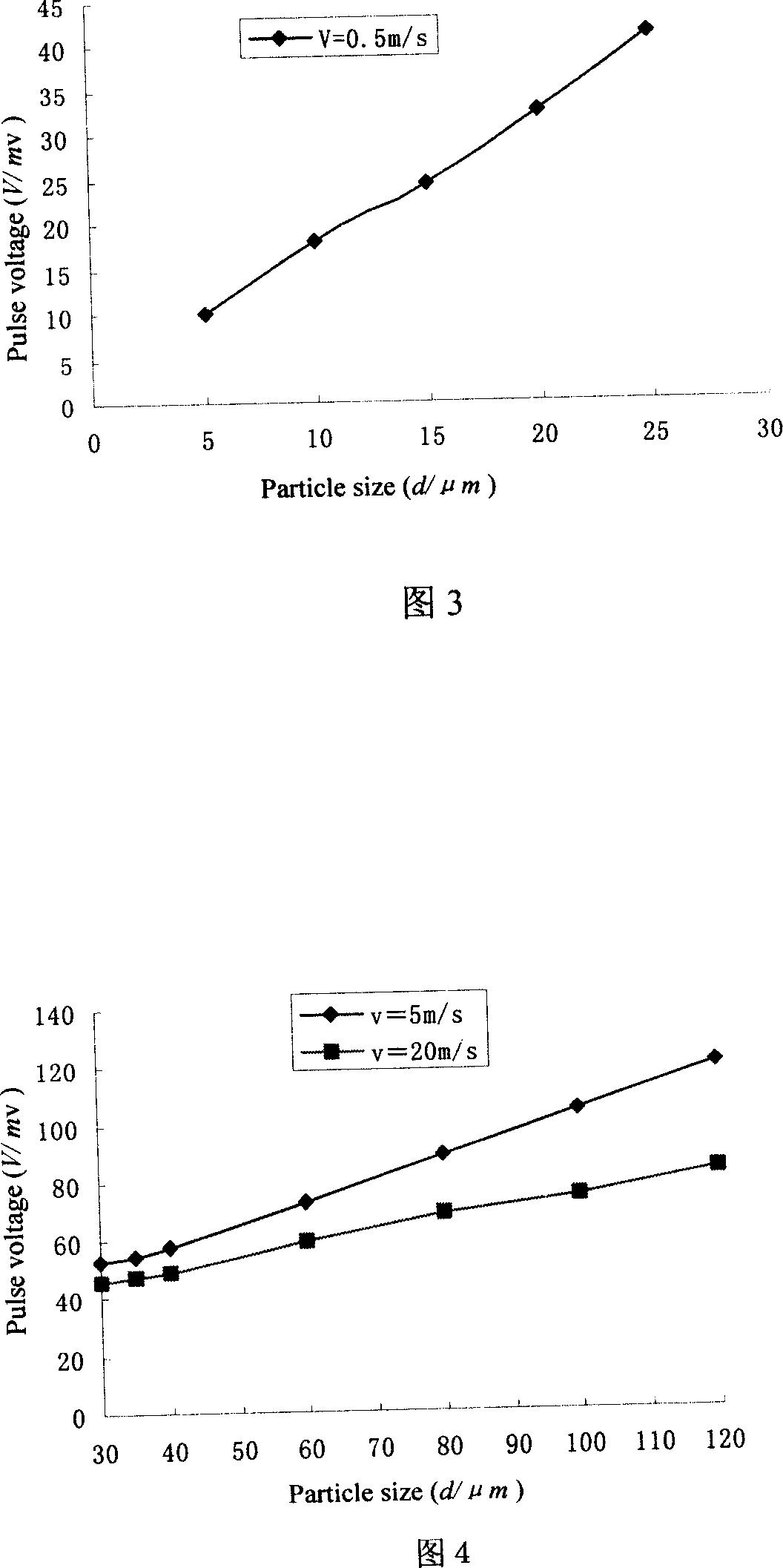

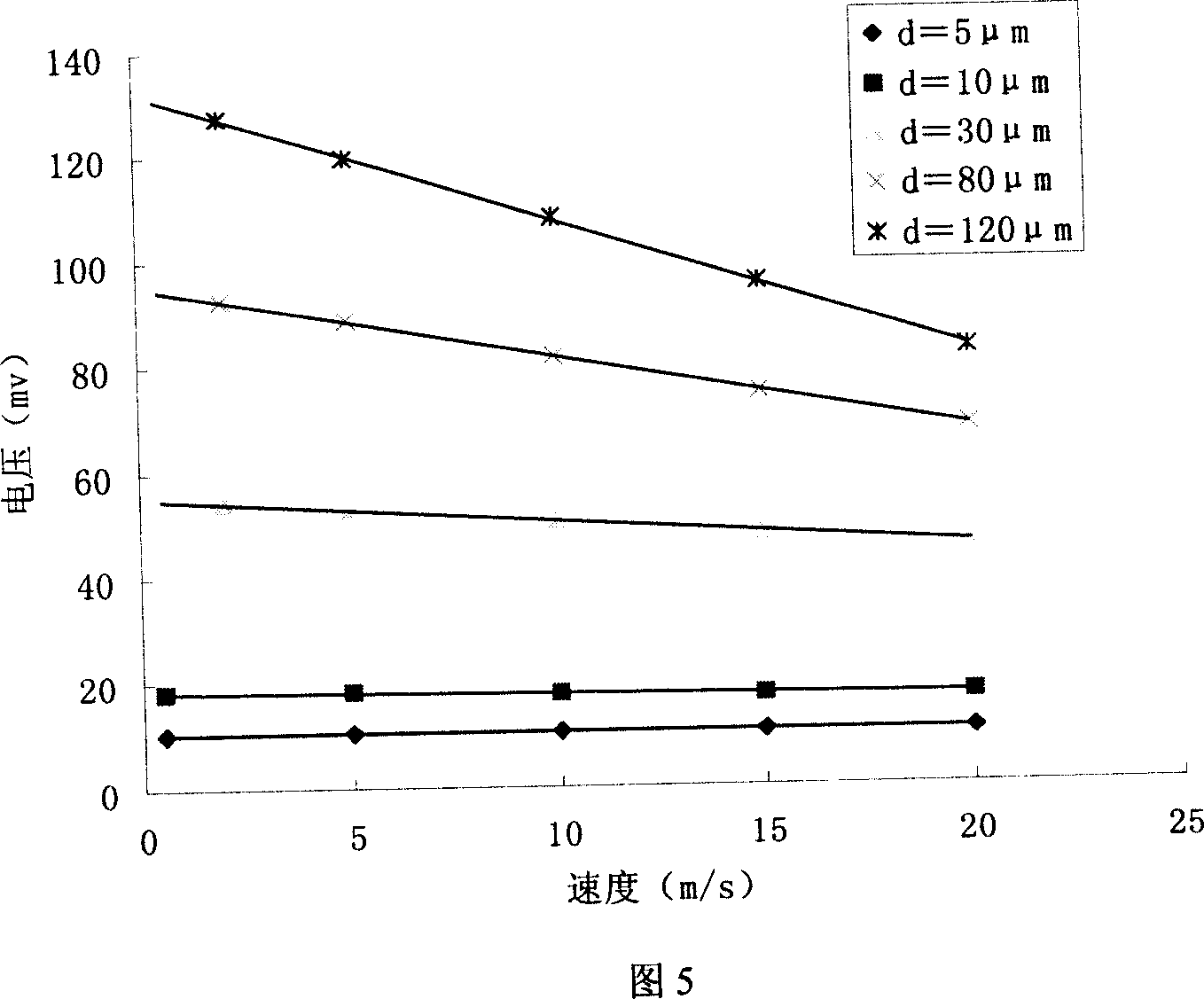

[0022] 1. Build a single particle measurement device based on the laser feedback effect (Fig. 2), select a single-mode helium-neon laser, R in Fig. 2 is a concave total reflection mirror, L is a focus conversion lens, focal length f = 20mm, and the concave total reflection mirror The focal length is 30mm, and F is the confocal focus. The confocal mode of the concave total reflection mirror R and the condenser lens L is adopted to form an additional resonant cavity with the laser resonant cavity. When the outgoing laser is in the additional resonant cavity, in the focal point F area, the appearance of the measured particles is very sensitive, and the scattered light is fed back to the laser, causing a change in the output laser power. PD is a ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com