Relative molecular mass controlled polyquaternium color fixing agent and synthesizing method thereof

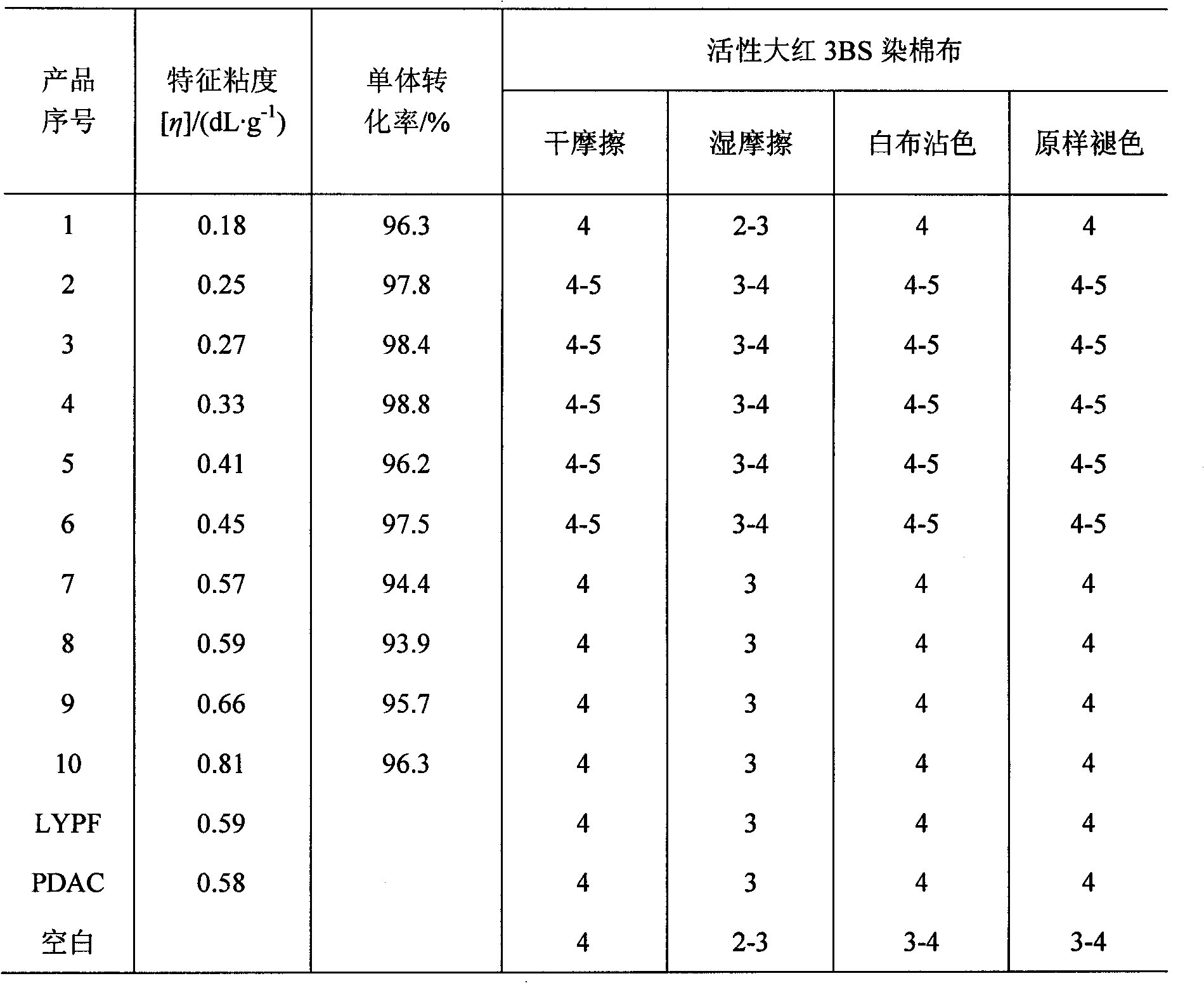

A relative molecular weight, polyquaternium technology, applied in dyeing, textiles and papermaking, etc., can solve the problem of limited reference value, no product yield and color fixing performance stability, no PDMDAAC color fixing agent dry friction and other problems. Research on fastness issues such as wet rubbing, etc., to achieve good color fixing performance, high product yield, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

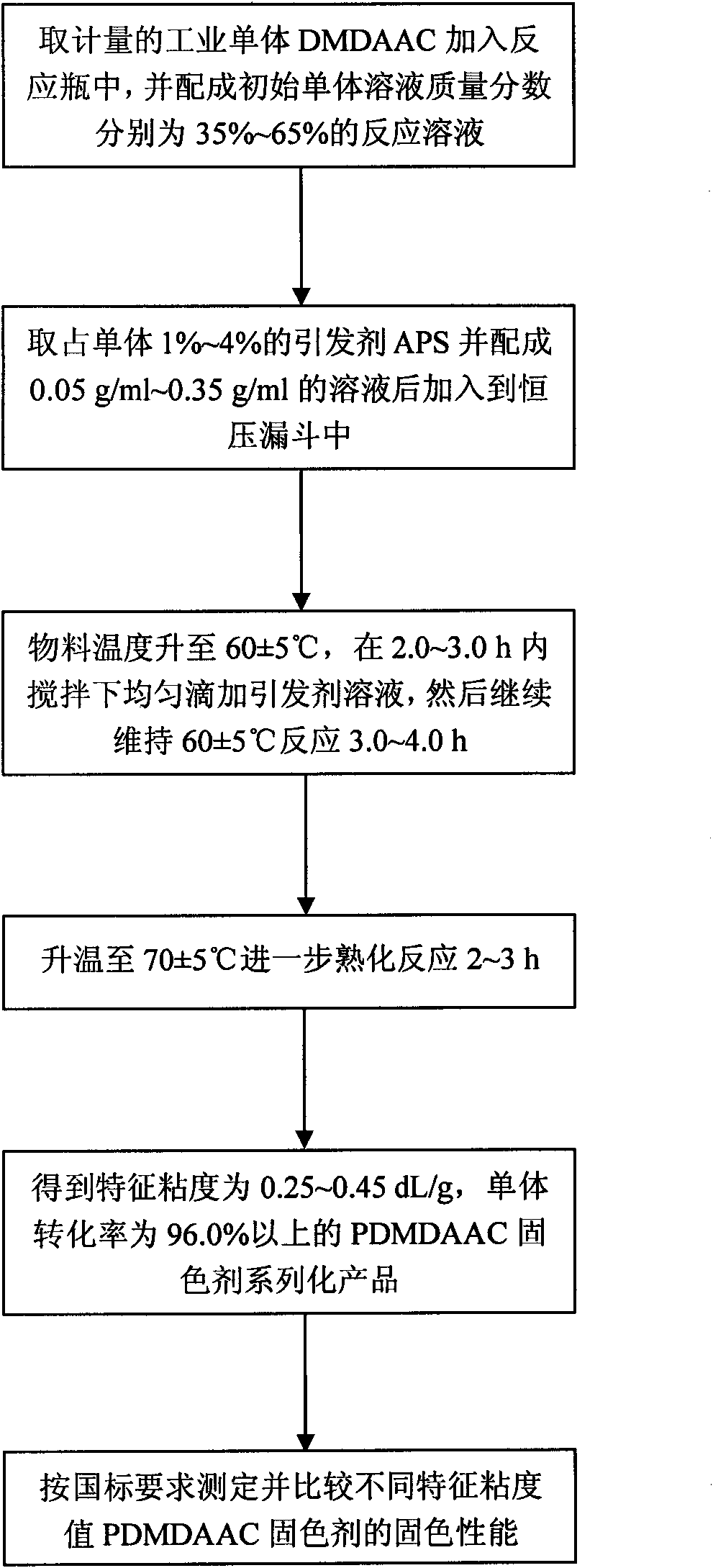

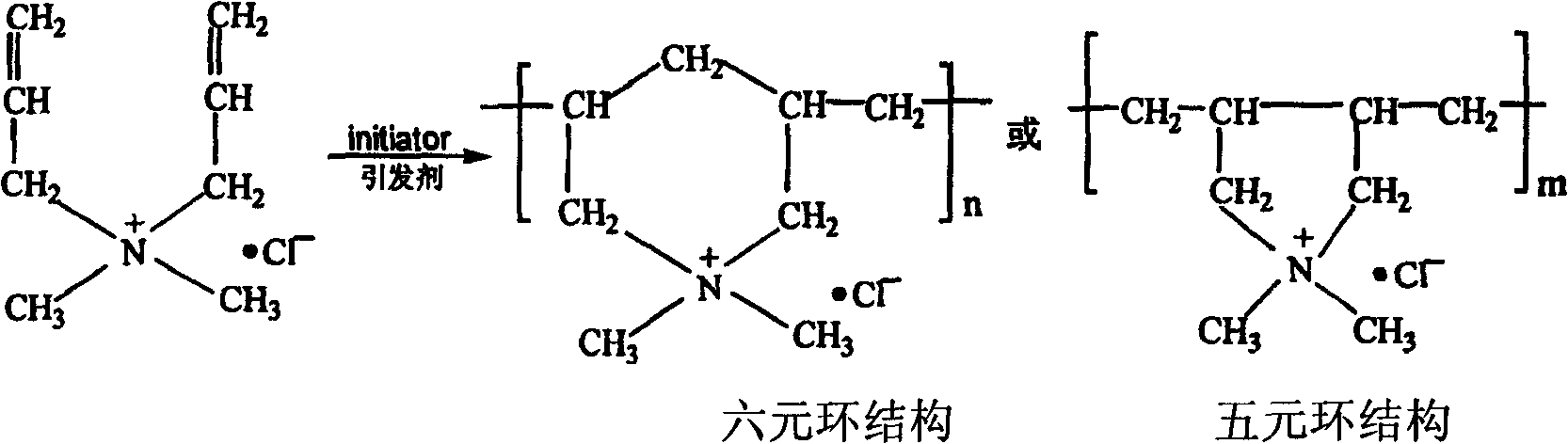

[0022] The relative molecular mass of the present invention is controlled polyquaternary ammonium salt color-fixing agent PDMDAAC and its synthetic method, and the steps are as follows:

[0023] In the first step, the metered industrial DMDAAC monomer is added into the reactor and prepared into a reaction solution whose mass fraction is 35%-65% of the initial monomer solution.

[0024] In the second step, the initiator ammonium persulfate APS accounting for 1%-4% of the mass of the reaction monomer DMDAAC is weighed and prepared into a 0.05g / ml-0.35g / ml initiator solution, and then added to the constant pressure funnel.

[0025] In the third step, the temperature of the reaction solution is raised to 60±5°C, and the ammonium persulfate (APS) initiator solution is evenly added dropwise from the constant pressure funnel under stirring, and the dropping time is 2.0-3.0h. Continue the reaction at ±5°C for 3.0-4.0h (the best total reaction time is 6h at 60±5°C).

[0026] The fourt...

Embodiment 1

[0033] The present invention is designed to effectively control the relative molecular mass of PDMDAAC within a specific viscosity range by synergistically controlling the reaction monomer concentration (initial monomer mass fraction) and the amount of initiator and other factors to obtain a corresponding high-efficiency color-fixing agent product. The specific steps as follows:

[0034] In the first step, take metered industrial DMDAAC monomer and add it into a clean four-necked flask and prepare a reaction solution with an initial monomer mass fraction of 35%;

[0035] In the second step, open the nitrogen valve, remove the air in the reaction bottle with a larger volume, and stop nitrogen after 30 minutes;

[0036] In the third step, take by weighing the initiator ammonium persulfate APS accounting for 4% of the mass of the reaction monomer DMDAAC and add it to the constant pressure funnel after being made into an initiator solution of 0.35g / ml;

[0037] In the fourth step...

Embodiment 2

[0041] The present invention is designed to effectively control the relative molecular mass of PDMDAAC within a specific viscosity range by synergistically controlling the reaction monomer concentration (initial monomer mass fraction) and the amount of initiator and other factors to obtain a corresponding high-efficiency color-fixing agent product. The specific steps as follows:

[0042] In the first step, take metered industrial DMDAAC monomer and add it into a clean four-neck flask to form a reaction solution with an initial monomer mass fraction of 50%;

[0043] In the second step, open the nitrogen valve, remove the air in the reaction bottle with a larger volume, and stop nitrogen after 30 minutes;

[0044] In the third step, take by weighing the initiator ammonium persulfate APS accounting for 4% of the mass of the reaction monomer DMDAAC and add it to the constant pressure funnel after being made into an initiator solution of 0.2g / ml;

[0045] In the fourth step, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com