Process for preparing high-molecular aliphatic polyester

A technology of aliphatic polyester and high molecular weight, which is applied in the field of preparation of aliphatic polyester, can solve the problems of difficult synthesis and difficult control of feeding ratio, and achieve the effect of fast reaction speed and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

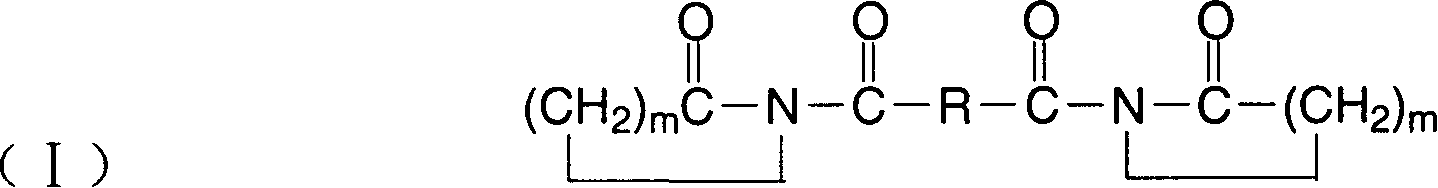

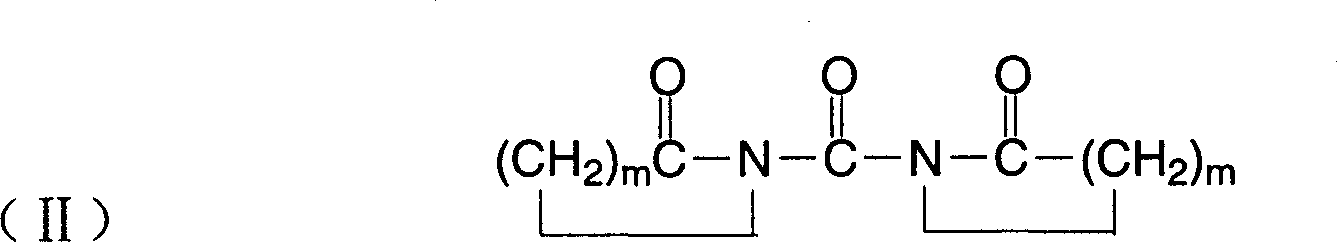

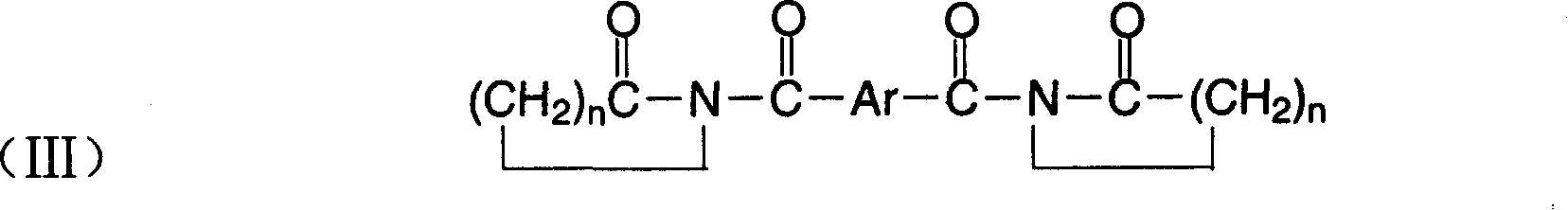

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the preparation of polybutylene adipate (PBA): with 50 parts of adipic acid, 37.5 parts of butanediol in parts by weight, 0.22 part of dibutyl tin oxide, 0.17 part of phosphorous acid under nitrogen protection , gradually increase the temperature from 140°C to 170°C for polycondensation, collect 70-80% of the generated water, switch to a decompression device, and gradually reduce the pressure to 1mmHg, and react at a temperature range of 190-220°C for 4-5 hours until the acid value is reduced to 3 or less, a PBA oligomer having a number average molecular weight of 3577 was obtained.

Embodiment 2

[0043] Example 2: 50 parts by weight of PBA oligomer (number average molecular weight is 3577) and 8.9 parts of N, N'-adipyl biscaprolactam prepared in Example 1 were reacted under nitrogen protection at 240°C under normal pressure for 30 Minutes, under reduced pressure (below 50mmHg) for 1.5 hours, the number average molecular weight of the polymer obtained was 26589.

Embodiment 3

[0044] Example 3: With reference to Example 1, the molar ratio of butanediol to adipic acid was changed to 1.17, and other conditions were exactly the same to synthesize PBA with a number average molecular weight of 5752. 50 parts by weight of PBA oligomers, 7.3 parts of N,N'-adipyl biscaprolactam, reacted at 240°C under normal pressure for 30 minutes under nitrogen protection, and reacted under reduced pressure (below 10mmHg) for 1.5 hours, the number of polymers obtained The average molecular weight is 32843.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com