Preparation method of para fanglun slurry cake

A para-aramid pulp and slurry technology, applied in textiles and papermaking, fiber processing, filament/thread forming, etc., can solve the problems of poor comprehensive physical and mechanical properties, low intrinsic viscosity of aramid pulp, long process flow, etc. problems, to achieve the effect of reducing pollution, good physical and mechanical properties, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

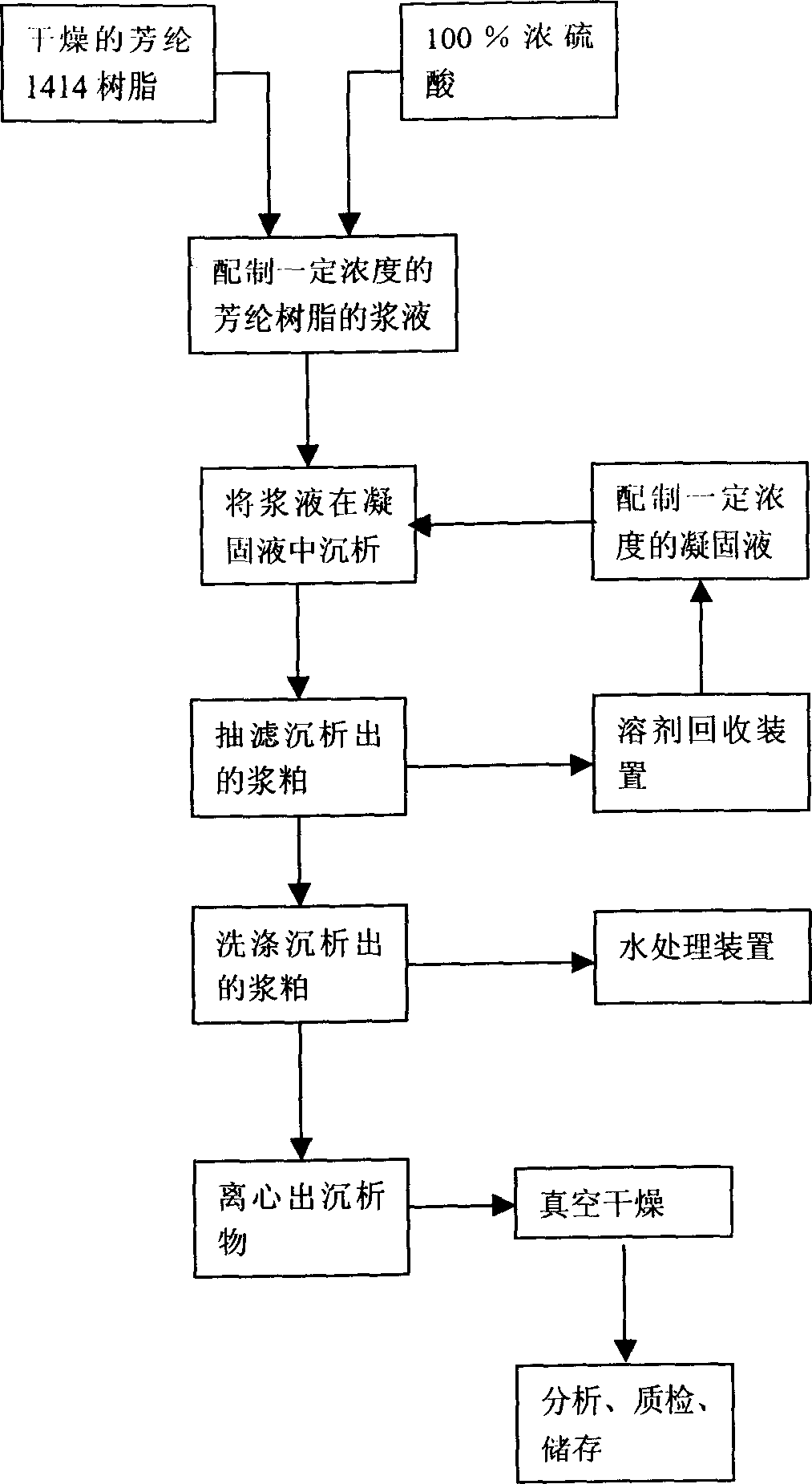

[0009] A method for preparing para-aramid pulp, comprising completely dissolving terephthalamide p-phenylene diamide resin in concentrated sulfuric acid with a concentration of 95%-101% to form a slurry, adding the slurry to a coagulation solution, and undergoing intense After stirring, the pulp-like fibers of p-phenylene terephthalamide are directly precipitated, washed and dried to obtain para-aramid pulp. The intrinsic viscosity of the said p-phenylene terephthalamide resin is 2.5-7.5 dl / g. Preferably, the intrinsic viscosity of the p-phenylene terephthalamide resin is 3.5-6.5 dl / g. In the slurry, the concentration of p-phenylene terephthalamide resin is 1%-15%. In the slurry, the concentration of p-phenylene terephthalamide resin is 3% to 8%.

[0010] The coagulation liquid is amide solvent or concentrated sulfuric acid or glycerin or acetic acid with a concentration of 60-85%.

[0011] The amide solvent is an aqueous solution or ethanol solution of N-methylpyrrolidone,...

example 1

[0013] Example 1. the aramid fiber 1414 resin (chemical name: terephthalamide p-phenylenediamine resin) that intrinsic viscosity is 3.5dl / g, in 100% concentrated sulfuric acid, dissolve completely and be formulated with the slurry that concentration is 5%, In 100% acetic acid solution at 20°C, at a stirring rate of 1500 rpm, the slurry rapidly precipitates into pulp-like fibers with a certain length-to-diameter ratio and a large specific surface area, and continues stirring for 2 minutes to wash the precipitate , suction filtration, and drying to obtain para-aramid pulp with rich surface hairiness, the average length is 2mm, and the aspect ratio is about 60-80.

example 2

[0014] Example 2. The aramid fiber 1414 resin that the intrinsic viscosity is 5.1dl / g is completely dissolved in 100% concentrated sulfuric acid and is formulated into a 4% slurry, and the slurry contains 50% glycerin in an aqueous solution at 30°C at 2000 rpm Rapidly precipitate into a pulp shape at a certain stirring rate, continue to stir for 2 minutes, wash the precipitate, filter with suction, and dry to obtain para-aramid pulp with rich surface hairiness, the average length is 2.5-3.5mm, and the aspect ratio It is about 80-90.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com