Method for preparing filaments for spinning through recycled PET (polythylene terephthalate) bottle

A technology of filaments and fragments, applied in the direction of single-component copolyester artificial filaments, etc., can solve the problem of high cost and achieve the effects of high production efficiency, perfect crystal structure and small interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

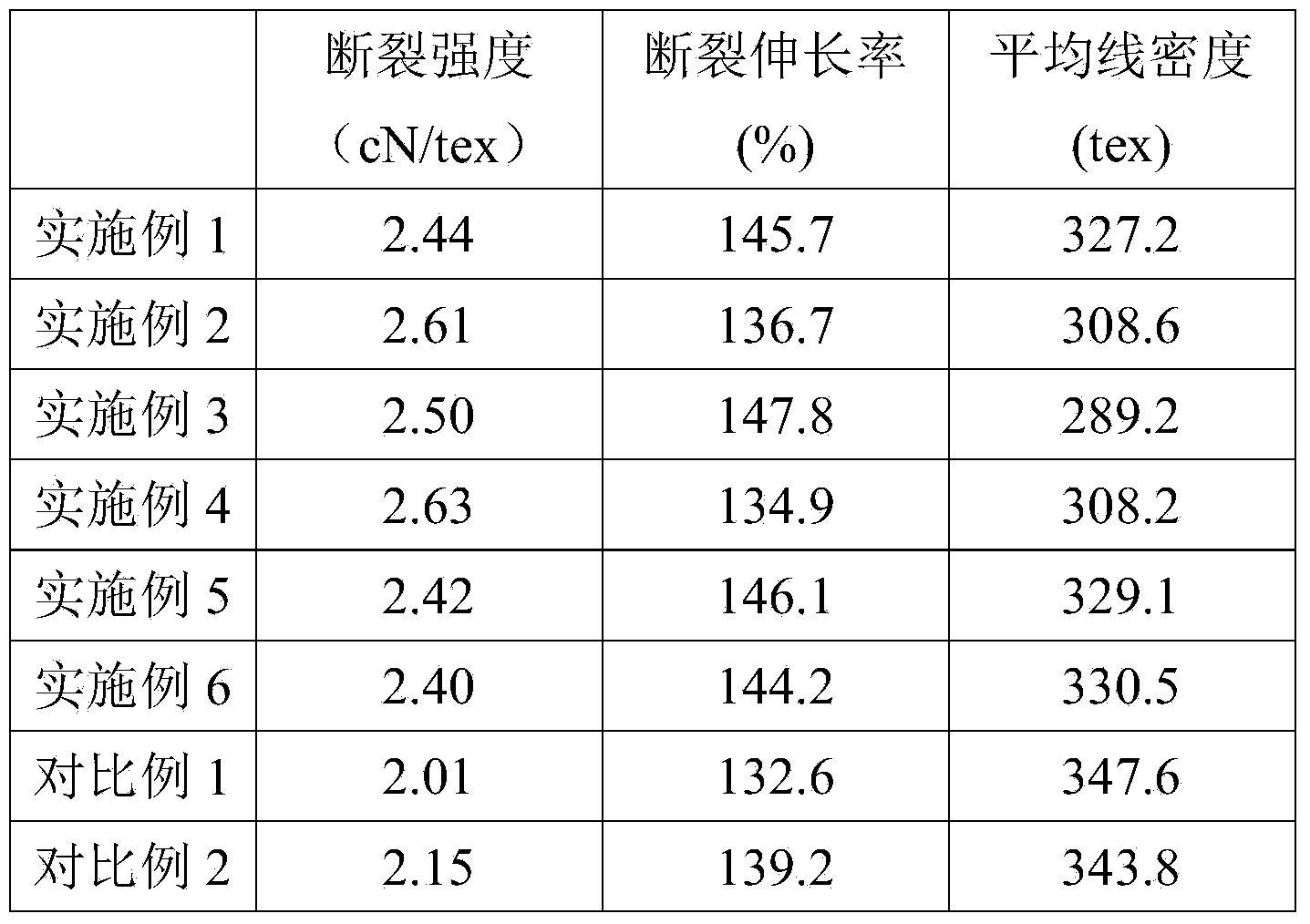

Examples

Embodiment 1

[0026] (1) The recycled PET bottles are crushed, washed and dried to obtain PET fragments. The average size of the PET fragments is 4mm;

[0027] (2) Add the PET chips to the parallel co-rotating twin-screw extruder, the temperature of the feeding section in the barrel of the parallel co-rotating twin-screw extruder: 200℃ in the first zone, 250℃ in the second zone; temperature in the melting zone: three, Zone 4 and zone 5 are both at 265°C, zone 6 is at 270°C; the homogenization zone temperature is 265°C; the screw speed is 60r / min, and the melt is obtained through melt blending and filtration;

[0028] (3) Send the melt to the closed reactor A, inject nitrogen into the closed reactor A, add 3-fluoro-1,2-propanediol under the agitation of the nitrogen flow, the quality of 3-fluoro-1,2-propanediol The mass percentage of the PET chips is 3%, and then the aluminum-based catalyst aluminum glycol is added. The mass percentage of the aluminum glycol aluminum and the mass percentage of 3-...

Embodiment 2

[0031] (1) The recycled PET bottles are crushed, washed and dried to obtain PET fragments. The average size of the PET fragments is 4mm;

[0032] (2) Add the PET chips to the parallel co-rotating twin-screw extruder, the temperature of the feeding section in the barrel of the parallel co-rotating twin-screw extruder: 200℃ in the first zone, 250℃ in the second zone; temperature in the melting zone: three, Zone 4 and Zone 5 are both at 265°C, zone 6 is 270°C; the homogenization zone temperature is 265°C; the screw speed is 60r / min, and the melt is obtained through melt blending and filtration;

[0033] (3) Send the melt to the closed reactor A, inject nitrogen into the closed reactor A, add 3-fluoro-1,2-propanediol under the agitation of the nitrogen flow, the quality of 3-fluoro-1,2-propanediol The mass percentage of the PET fragments is 4%, and then the aluminum-based catalyst aluminum glycol is added. The mass percentage of the aluminum glycol aluminum to the mass percentage of 3-...

Embodiment 3

[0036] (1) The recycled PET bottles are crushed, washed and dried to obtain PET fragments. The average size of the PET fragments is 4mm;

[0037] (2) Add the PET chips to the parallel co-rotating twin-screw extruder, the temperature of the feeding section in the barrel of the parallel co-rotating twin-screw extruder: 200℃ in the first zone, 250℃ in the second zone; temperature in the melting zone: three, Zone 4 and Zone 5 are both at 265°C, zone 6 is 270°C; the homogenization zone temperature is 265°C; the screw speed is 60r / min, and the melt is obtained through melt blending and filtration;

[0038] (3) Send the melt to the closed reactor A, inject nitrogen into the closed reactor A, add 3-fluoro-1,2-propanediol under the agitation of the nitrogen flow, the quality of 3-fluoro-1,2-propanediol The mass percentage of PET fragments is 5%, and then the aluminum-based catalyst aluminum acetate is added. The mass percentage of aluminum acetate and 3-fluoro-1,2-propanediol is 0.06%. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com