Water solution polymerization preparation method for dimethyl diallyl ammonium chloride and acrylamide copolymers

A technology of dimethyl diallyl ammonium chloride and acrylamide copolymer, which is applied in the field of preparation of water-soluble polymers, and can solve the problems of restricting the industrial application of the preparation process, low molecular weight of PDA products, and restricting the industrialization of the preparation process, etc. problems, to achieve the effect of simple production process, low material cost and high relative molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

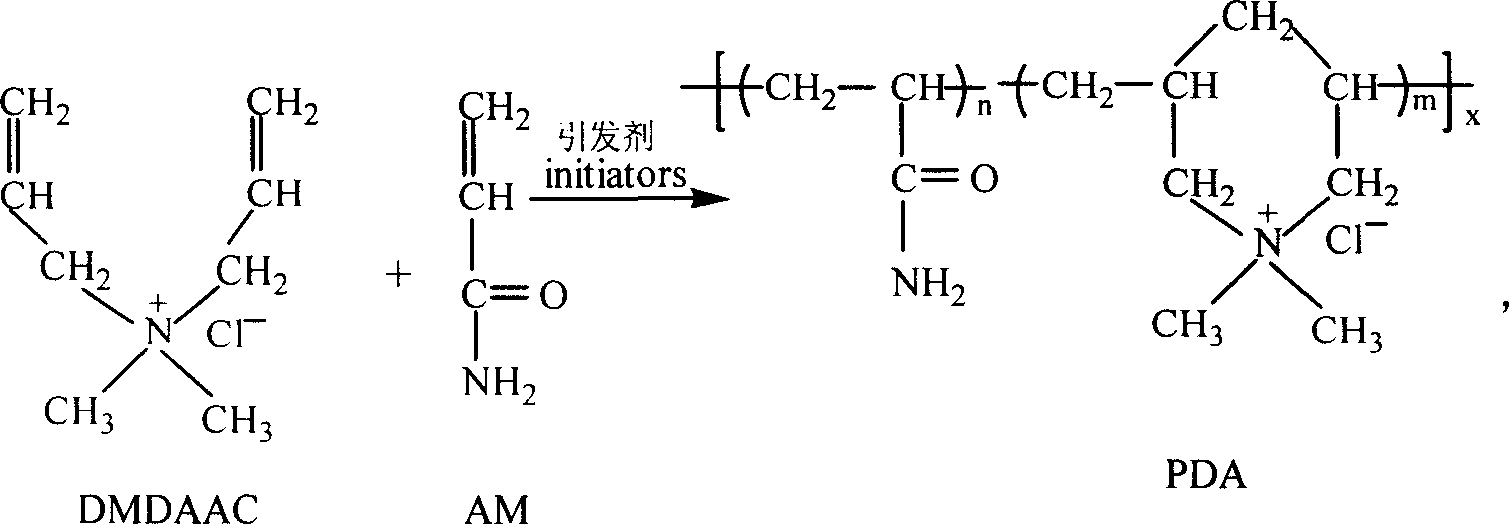

Method used

Image

Examples

Embodiment 1

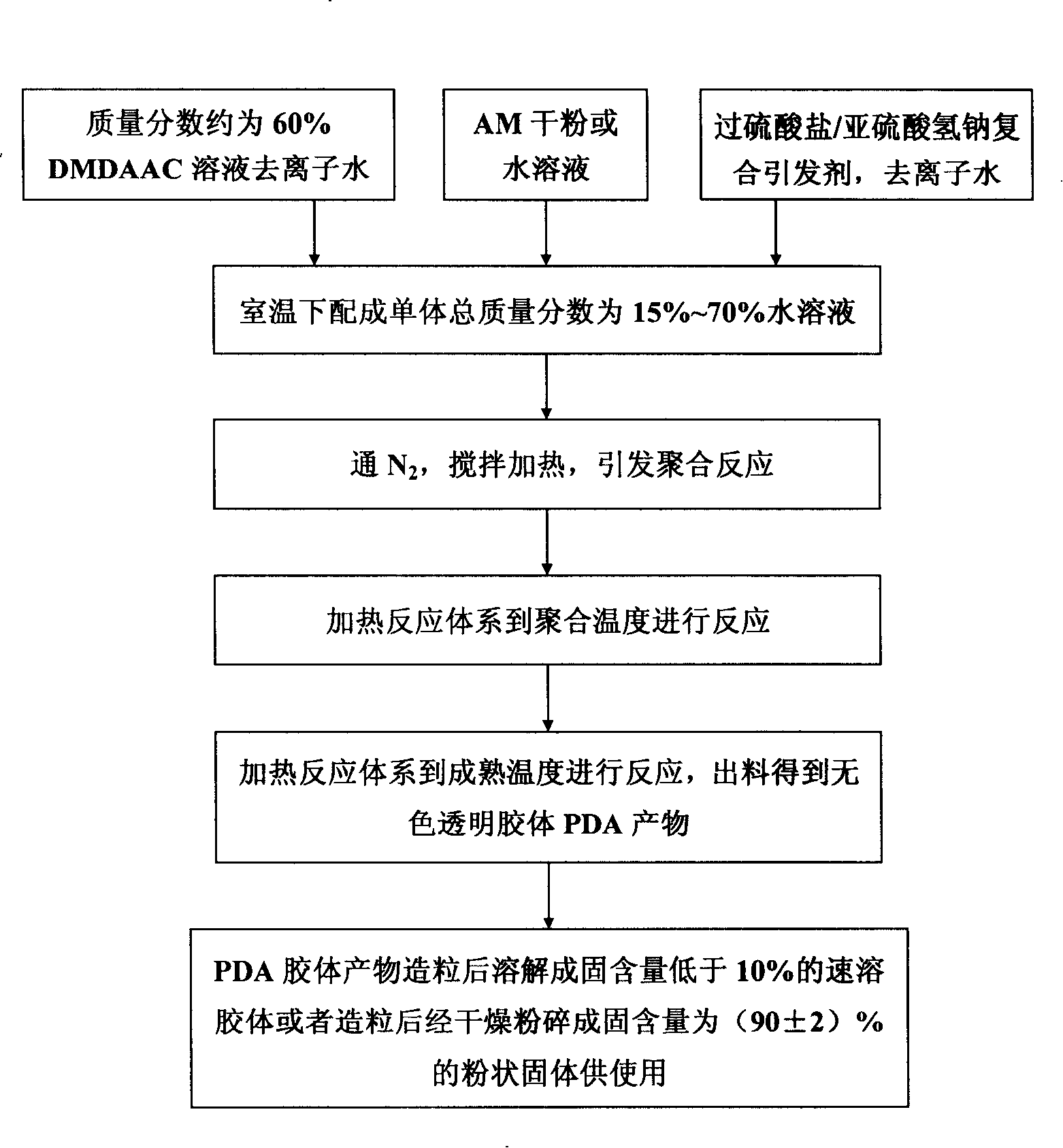

[0046] Embodiment 1: the step of the aqueous solution polymerization system method of the copolymer PDA of dimethyl diallyl ammonium chloride of the present invention and acrylamide is:

[0047] In the first step, add 0.28kg of industrial one-step cationic monomer DMDAAC solution with a mass fraction of 60% in a 15L reactor at room temperature (≤25°C), 1.42kg of industrial monomer AM dry powder (or 4.73kg of an aqueous solution containing AM30%) ), through N 2 Add 0.04kg of ammonium persulfate with a mass fraction of 0.36% and an initiator solution with a mass ratio of ammonium persulfate to sodium bisulfite of 1:2.00±0.05, and add 8.20kg (or 4.89kg) of deionized water under stirring;

[0048] The second step is to enter N 2 , stir and heat up the reaction solution to the polymerization temperature of 28±2°C, stop stirring, and pass N 2 , react for 3 to 4 hours;

[0049] The third step is to reheat the reaction system to the polymerization temperature of 60±2°C and react fo...

Embodiment 2~7

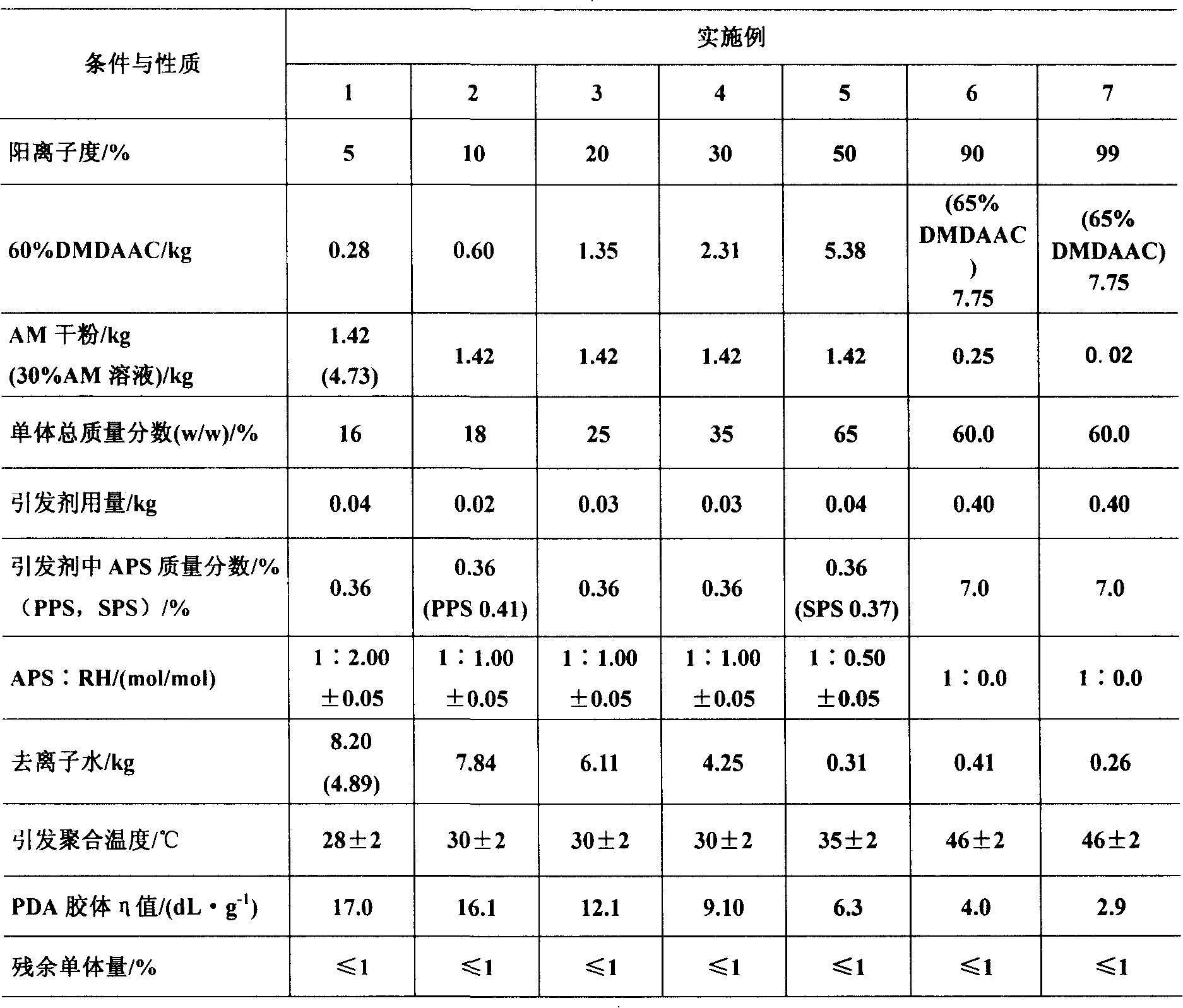

[0052] Embodiments 2-7: Except that the preparation conditions and results different from Embodiment 1 are listed in the following table, all the other steps are the same as Embodiment 1.

[0053] Preparation process conditions and product properties different from embodiment 1 in embodiment 2~7

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com