Poly(ethylene 2,5-furandicarboxylate), and preparation method thereof

A technology of ethylene glycol furandicarboxylate and furandicarboxylic acid, which is applied in the field of polyester, can solve the problems of terephthalic acid production limitation and high price, and achieve the effects of high synthesis efficiency, simple operation and wide sources

Inactive Publication Date: 2011-09-21

CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

View PDF5 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

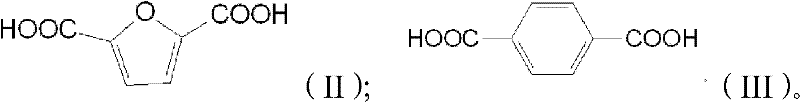

PET is synthesized from terephthalic acid and ethylene glycol through polycondensation reaction, where the molecular formula of ethylene glycol is C 2 h 6 o 2 , the molecular weight is 62.07, and the CAS registration number is 107-21-1. It can be synthesized not only by direct hydration of ethylene oxide, but also by biological fermentation process. It has a wide range of sources and is cheap; the molecular formula of terephthalic acid is C 8 h 6 o 4 , the molecular weight is 166.13, and the CAS registration number is 100-21-0. Although terephthalic acid is the dicarboxylic acid with the largest output, terephthalic acid is a chemical product that depends on petroleum resources. With the depletion of petroleum resources, the production of terephthalic acid will also be limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

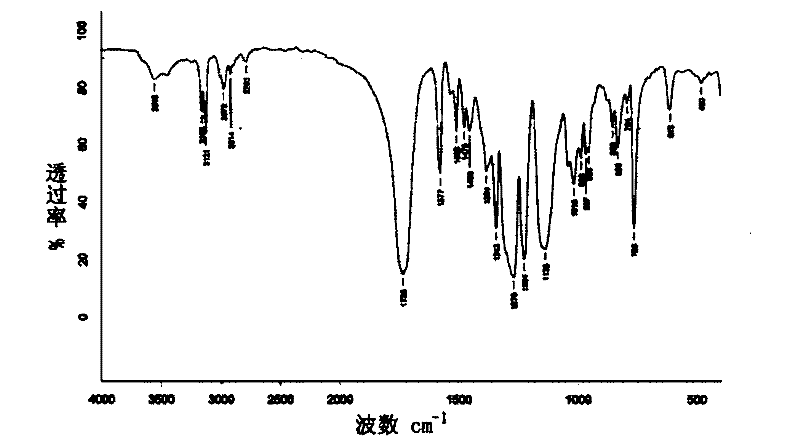

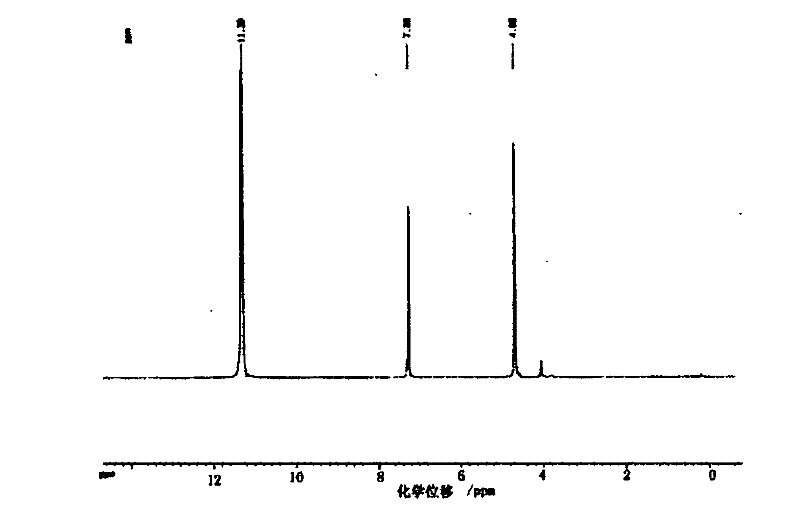

The invention provides poly(ethylene 2,5-furandicarboxylate), which contains the repeating units shown in formula (I) and has a characteristic viscosity not smaller than 0.2 dL / g. The invention also provides a preparation method for poly(ethylene 2,5-furandicarboxylate) provided by the technical scheme, which comprises the following steps of: carrying out esterification reaction on 2,5-furandicarboxylic acid and ethylene glycol under the action of a tin catalyst to obtain a first intermediate product, wherein the esterification reaction pressure is 0.1-0.4 MPa; and carrying out condensation polymerization reaction on the first intermediate product under the pressure of 10-70 Pa to obtain poly(ethylene 2,5-furandicarboxylate). Experiments show that poly(ethylene 2,5-furandicarboxylate) provided by the invention is dark brown, and has a characteristic viscosity of not smaller than 0.2 dL / g, a glass transition temperature of 60-63 DEG C and a melting point of 210-215 DEG C.

Description

Polyethylene glycol 2,5-furandicarboxylate and preparation method thereof technical field The invention belongs to the technical field of polyester, and in particular relates to polyethylene 2,5-furandicarboxylate and a preparation method thereof. Background technique Polyester is a general term for polymers obtained by polycondensation of polyols and polybasic acids. It is a class of engineering plastics with excellent performance and a wide range of uses, including polyethylene terephthalate (PET), polybutylene terephthalate (PBT) and polyarylate, etc. Among them, PET is widely used in the production of engineering plastics and mechanical parts due to its good fiber formation, mechanical properties, wear resistance, creep resistance and electrical insulation. PET is synthesized from terephthalic acid and ethylene glycol through polycondensation reaction, where the molecular formula of ethylene glycol is C 2 h 6 o 2 , the molecular weight is 62.07, and the CAS registr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G63/42C08G63/78

Inventor 周光远姜敏刘茜张强叶冲

Owner CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com