Stain removal process using combination of low and high speed spin

a high-speed spin and stain removal technology, applied in the field of clothing article treatment, can solve problems such as the potential risk of “suds lock” and achieve the effect of high spin speed and high spin speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

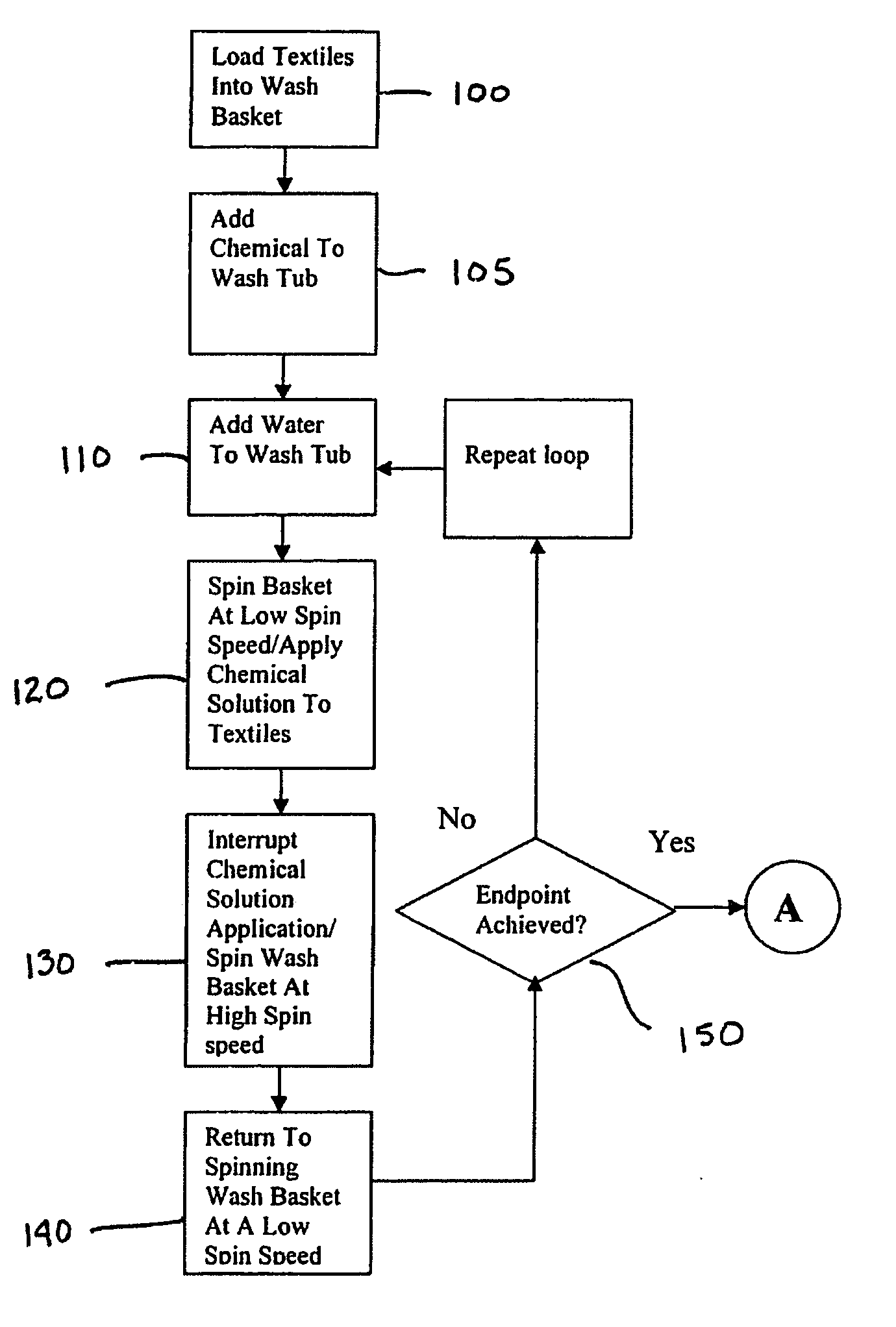

[0047] Table 1, below, summarizes the steps of a detergent pretreatment process. Table 2, below, summarizes the steps of a concentrated bleach treatment process.

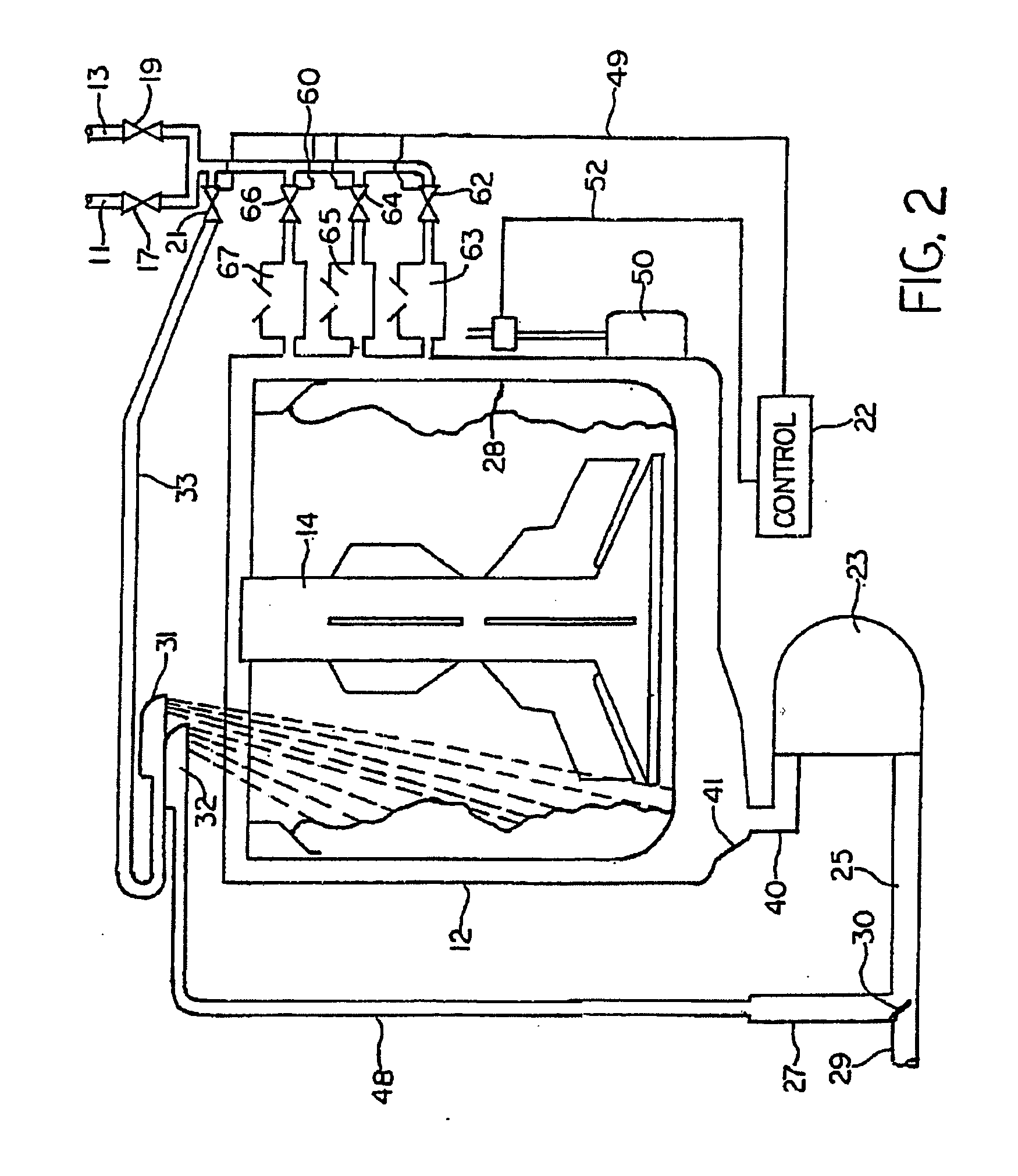

[0048] In the stain removal pretreatment process of Table 1, the manufacturer's recommended amount of powdered or liquid detergent is added to the wash tub of the automatic washer via the detergent dispenser. Warm tap water is added to the wash tub through the main wash dispenser in step 3. The steps 1-13 of Table 1 embody a concentrated detergent stain removal pretreatment process of this invention.

TABLE 1DescriptionDriveofMotorDrive MotorStepSequenceNotesActionProfileDuration (Min:Sec)1coastwaitOFFspeed = 02spin ONspinspeed = 20; ramp = 303fillWL = 15 mmOFF4recirc ONspin0:151recirc OFFspin0:206spin ONspinspeed = 100; ramp = 70:207spin ONspinspeed = 140; ramp = 800:158spin ONspinspeed = 190; ramp = 900:159spin ONspinspeed = 280; ramp = 900:2510coastOFF11spin ONLOOP: gospinspeed = 20; ramp = 30back to step#3; repeatloop 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com