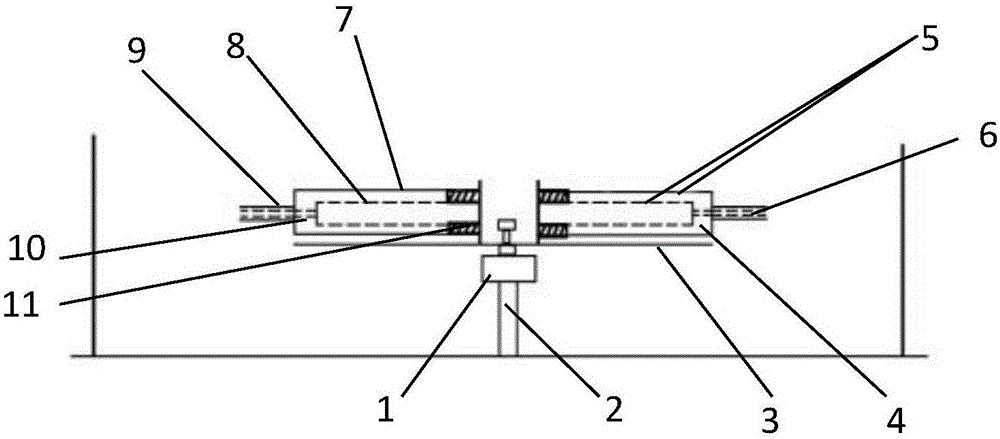

Coaxial centrifugal spinning device and method

A technology of centrifugal spinning and centrifugal devices, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of imperfect technology, complicated equipment, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

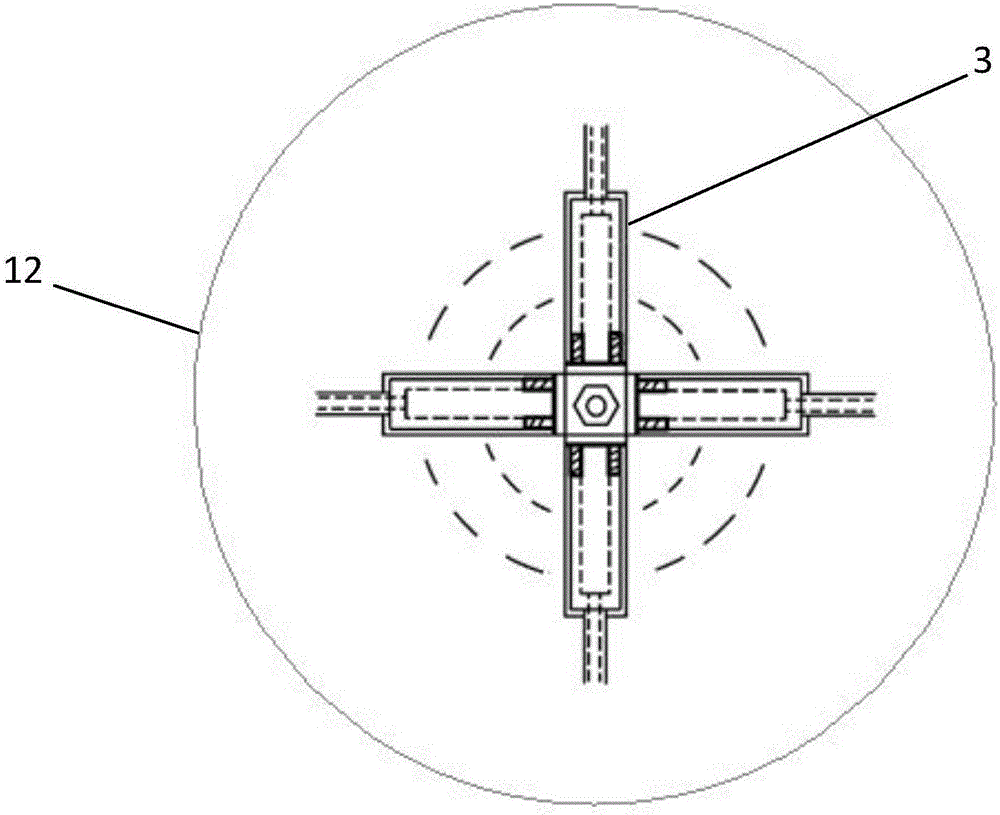

Embodiment 1

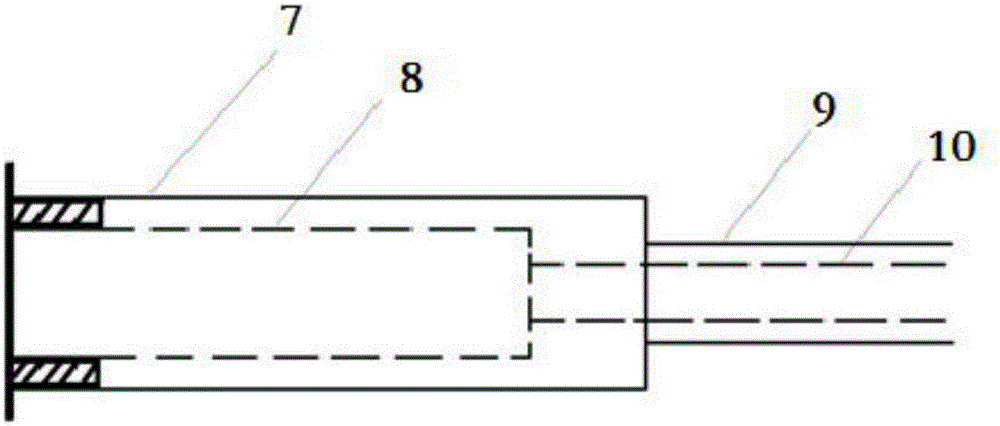

[0039] A certain amount of polyvinylpyrrolidone (PVP) with an average molecular weight of 1.5 million is dissolved in absolute ethanol, and mechanically stirred to completely dissolve the PVP to obtain a PVP ethanol solution with a mass fraction of 15-25% as the inner layer spinning solution; Dissolve a certain amount of polyacrylonitrile (PAN) with a weight average molecular weight of 150,000 in a mixed solution of a certain amount of N,N-dimethylformamide (DMF) and acetone at a mass ratio of 4:1, mechanically Stir to completely dissolve the PAN to obtain a PAN solution with a mass fraction of 10-20% as the outer layer spinning solution. Inject the inner and outer spinning solutions into the inner and outer centrifuge tubes respectively, the inner and outer diameters of the inner spinning needles 10 are 0.41mm and 0.7mm respectively, and the inner and outer diameters of the outer spinning needles 9 are respectively 0.84mm and 1.26mm; Adjust the rotational speed of the centrif...

Embodiment 2

[0041] Dissolve a certain amount of polyvinylpyrrolidone (PVP) with an average molecular weight of 1.5 million in absolute ethanol, and mechanically stir to completely dissolve the PVP to obtain a PVP ethanol solution with a mass fraction of 10--20% as the inner layer spinning solution ; A certain amount of polyvinylidene fluoride (PVDF) with a weight average molecular weight of 250,000 is dissolved in a mixed solution of a certain amount of N,N-dimethylformamide (DMF) and acetone in a mass ratio of 4:1 , Mechanical stirring to completely dissolve the PVDF to obtain a PVDF solution with a mass fraction of 15-25% as the outer layer spinning solution. Inject the inner and outer spinning solutions into the inner and outer centrifuge tubes respectively. The inner and outer diameters of the inner spinning needles are 0.3mm and 0.6mm respectively, and the inner and outer diameters of the outer spinning needles are respectively 0.8mm and 1.2mm; The rotation speed of the device is 500...

Embodiment 3

[0043] Dissolve a certain amount of polyacrylonitrile (PAN) with a weight average molecular weight of 150,000 in a mixed solution of a certain amount of N,N-dimethylformamide (DMF) and acetone at a mass ratio of 4:1, mechanically Stir to dissolve PAN completely, and obtain a PAN solution with a mass fraction of 5%-10%, as an inner layer spinning solution; dissolve a certain amount of polymethyl methacrylate (PMMA) with a weight average molecular weight of 110,000 in a certain amount N,N-dimethylformamide (DMF) and distilled water are mixed in the mixed solution of mass ratio 4:1, and mechanical stirring makes PMMA dissolve completely, obtains the PMMA solution that mass fraction is 10-20%%, as external layer spinning solution. Inject the inner and outer spinning solutions into the inner and outer centrifuge tubes respectively, the inner and outer diameters of the inner spinning needles are 0.4mm and 0.7mm respectively, and the inner and outer diameters of the outer spinning ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Inner and outer diameter | aaaaa | aaaaa |

| Inner and outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com