Cable fault simulating and positioning system

A cable fault and positioning system technology, applied in the fault location, using the pulse reflection method to detect faults, teaching models, etc., can solve problems such as waste of manpower, material resources, bad social impact, power loss, etc., to achieve reliable work, easy to carry, The effect of simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

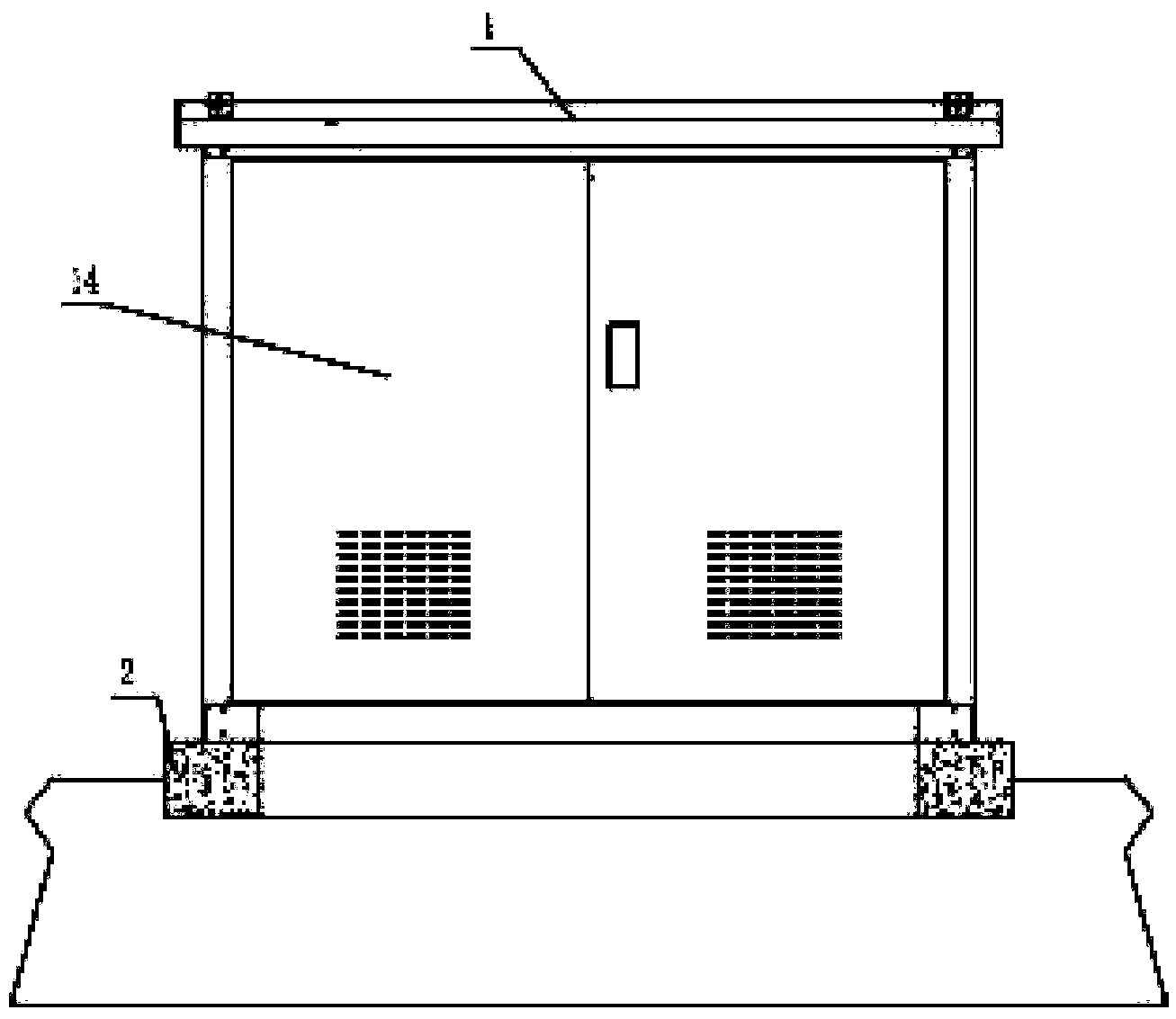

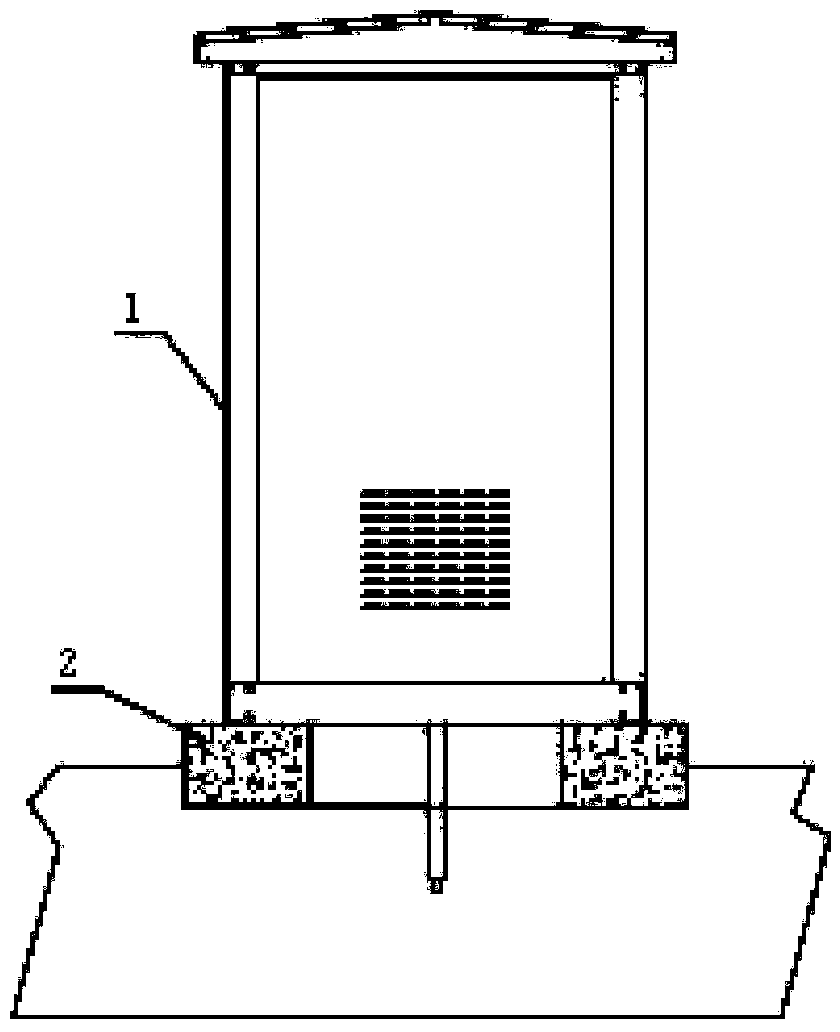

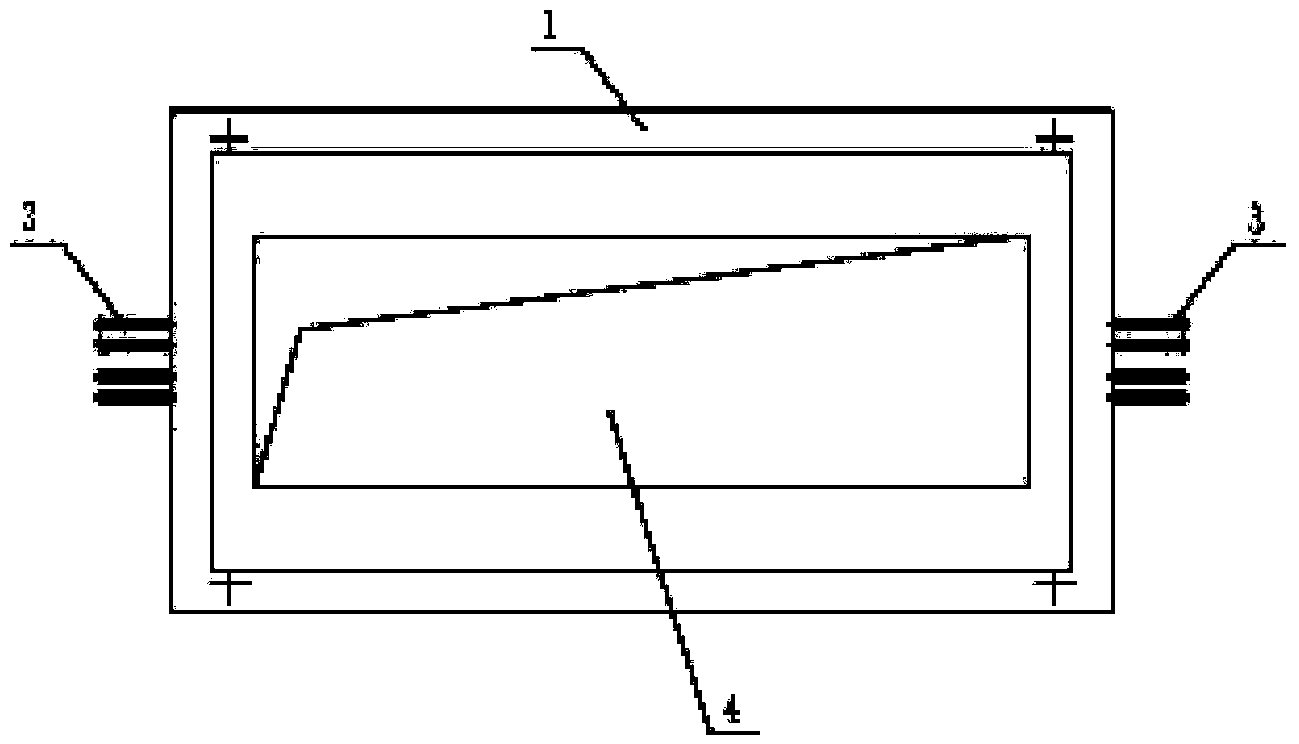

[0024] See Figure 1-9 , the cable fault simulation and positioning system of this embodiment includes: a cable fault simulation box 1 located on the concrete foundation 2, an electrode mounting plate 5 located in the cable fault simulation box 1, and three electrodes located on the electrode mounting plate 5 One incoming electrode 6 and three outgoing electrodes 7; three incoming electrodes 6 are connected with the three-phase cores in the incoming cable 8 respectively, and three outgoing electrodes 7 are respectively connected with the three-phase cores in the first outgoing cable 9 connected. The reinforced concrete foundation 2 is fixedly connected with the cable fault simulation box 1 through foundation feet and expansion bolts. Both sides of the bottom of the cable fault simulation box 1 are provided with threading pipes 3, the center of the bottom of the cable fault simulation box 1 has an opening 4, and the front end of the cable fault simulation box 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com