Measuring method and apparatus for mask bench scanning inclination

A measurement method and a technology of a measurement device, which are applied in the direction of photolithography exposure devices, microlithography exposure equipment, etc., can solve the problems of large random errors, consumption of glue-coated silicon wafers, and long time consumption, so as to avoid errors and reduce energy consumption. time, the effect of simplifying the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The method and device for measuring the scanning tilt of the mask stage of the present invention will be further described in detail in conjunction with embodiments below.

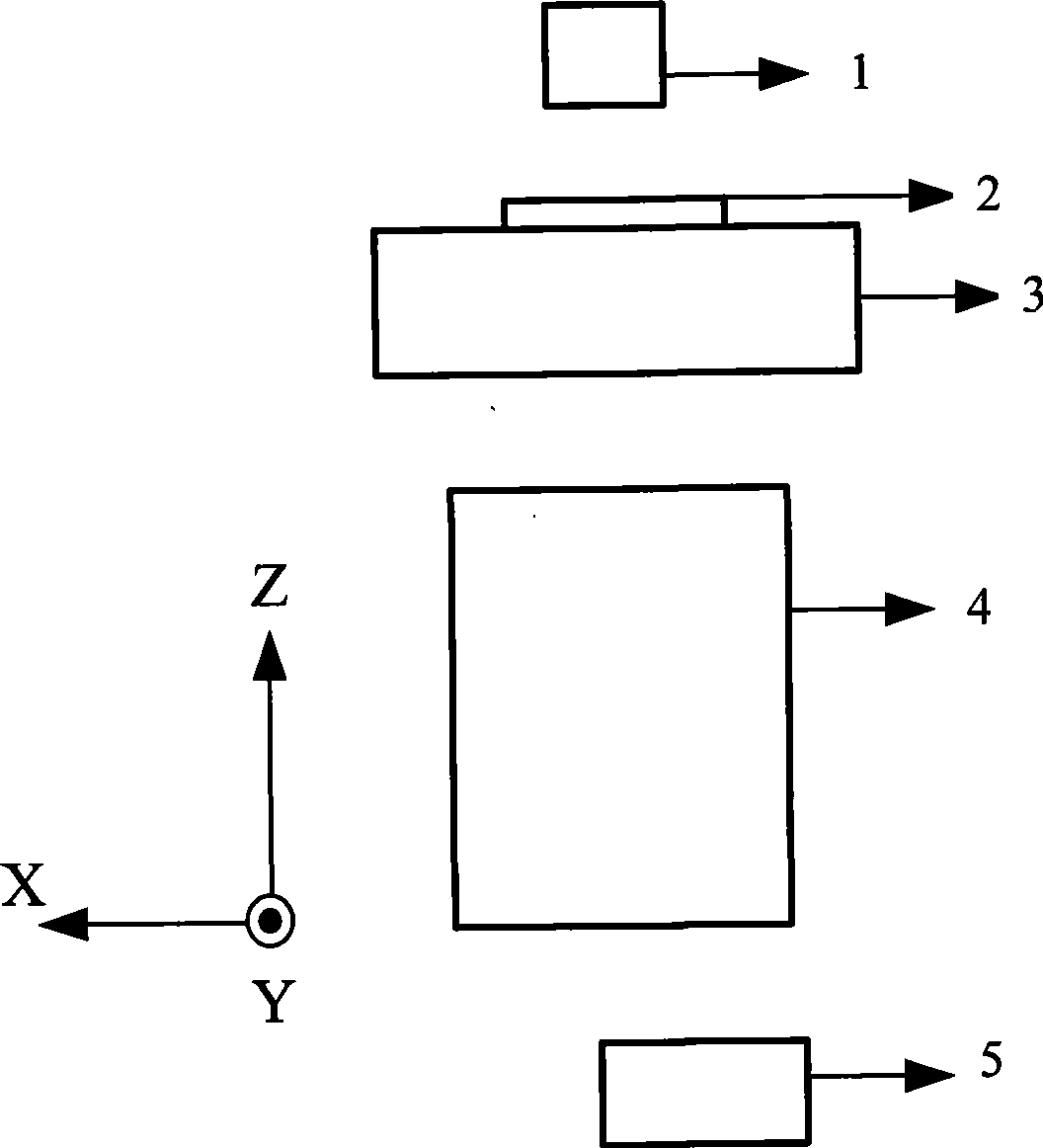

[0023] see image 3 A schematic structural diagram of a lithography machine system is shown, and the lithography machine system includes: an exposure light source 1 , a mask table 3 carrying a test mask 2 , a projection objective lens 4 and an image sensor system 5 .

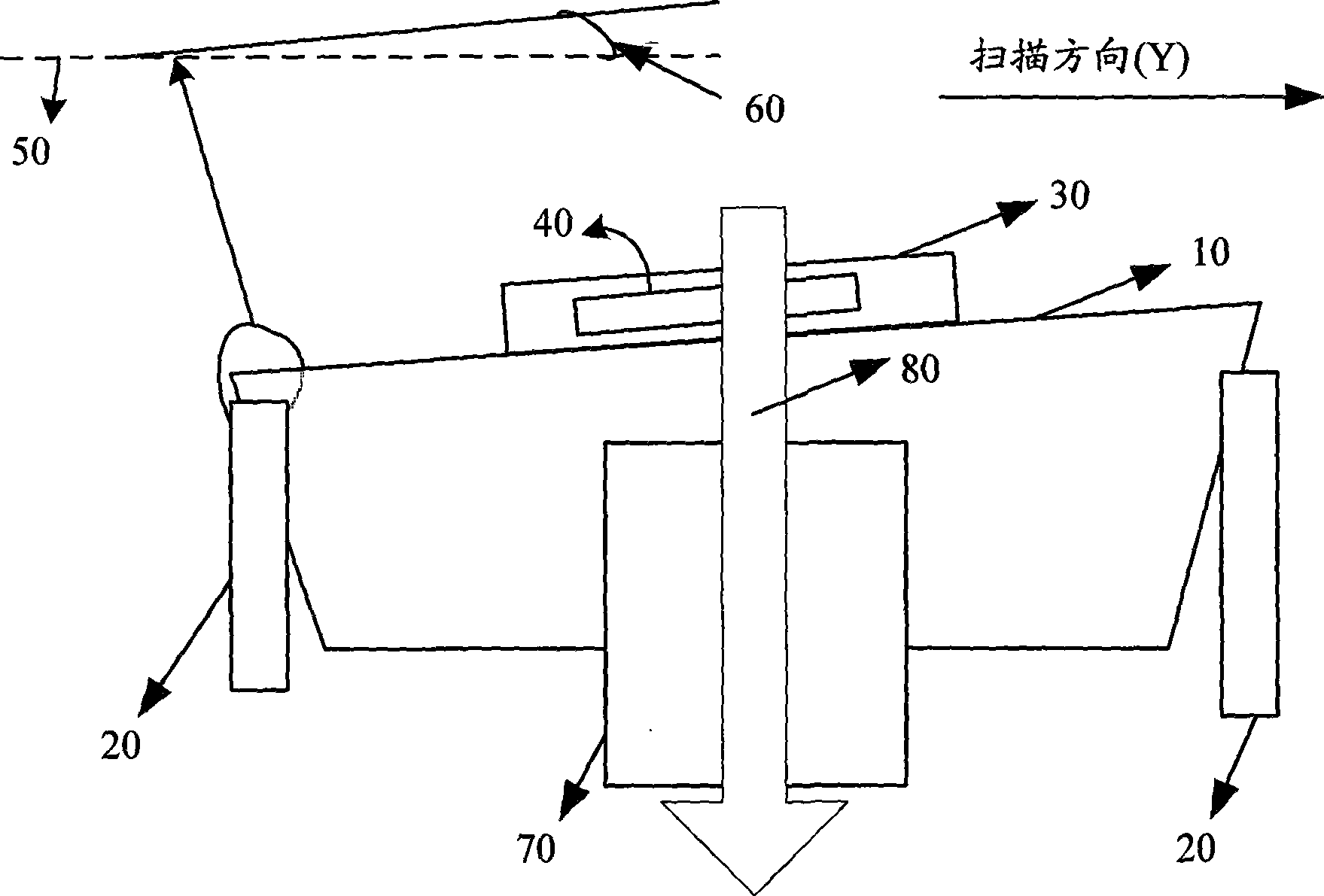

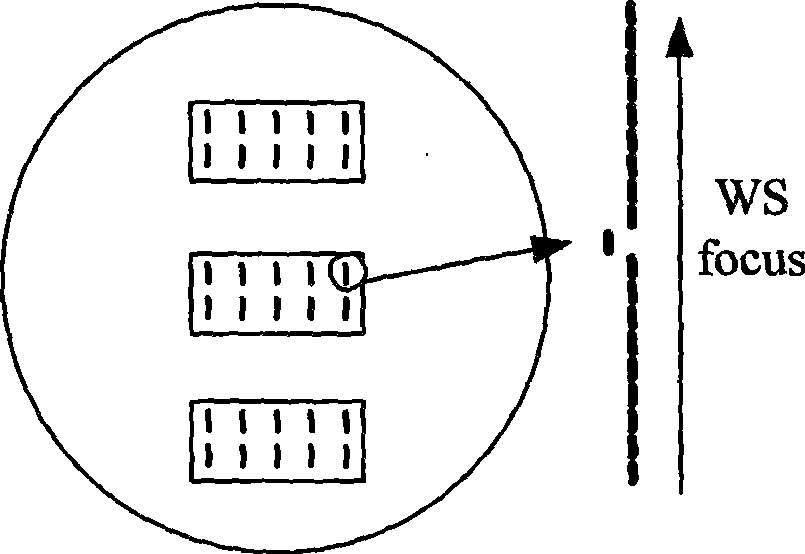

[0024] Next, please combine Figure 4 , which shows a schematic diagram of the process of measuring the scanning tilt of the mask stage in the present invention. As shown in the figure, the test mask 2 can move along the scanning direction (Y direction) of the mask table driven by the mask table 3, and the movement can be forward or reverse. There are a plurality of alignment marks 20 on the test mask 2, and the structure of these alignment marks can be as follows figure 2 As shown, other marking structures can also be used, mainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com