Determination method for dispersibility of carbon nano-tubes in resin

A carbon nanotube and determination method technology, applied in nanotechnology, measuring device, particle size analysis and other directions, can solve the problems of cumbersome sample preparation, long detection period, difficult real-time detection, etc., to overcome the cumbersome steps, reduce the test cost, The effect of the simple and easy measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

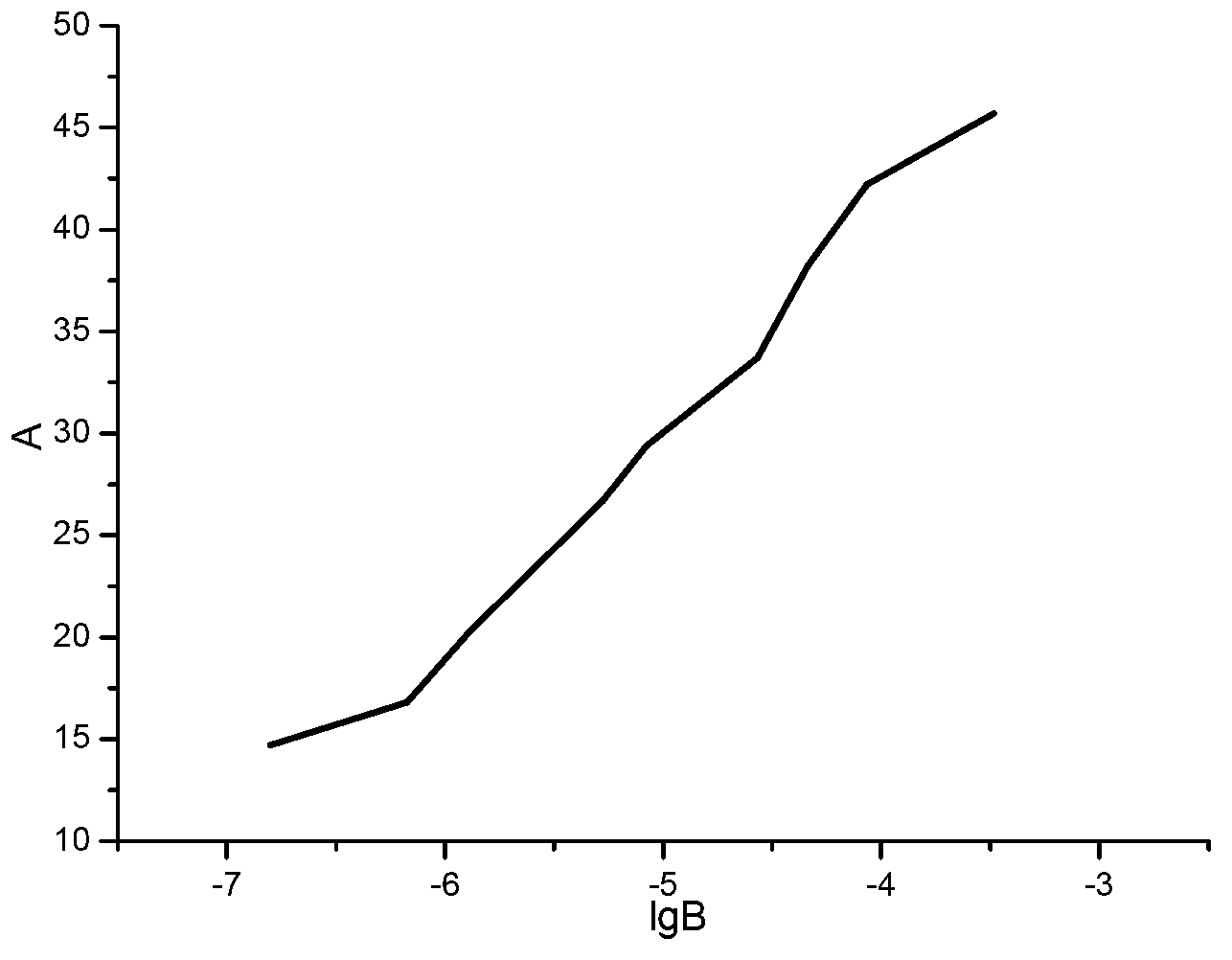

Embodiment 1

[0045] Step (1), using different methods to prepare epoxy resin with a mass percentage of carbon nanotubes of 1%, including mechanical stirring, ultrasonic dispersion, and shear dispersion, among which three different methods of mechanical stirring, ultrasonic dispersion, and shear dispersion The process conditions were changed respectively, and a total of 9 kinds of epoxy resins with a mass percentage of carbon nanotubes of 1% were prepared as the resins to be tested, numbered 1-9. The carbon nanotubes are multi-walled carbon nanotubes modified by carboxylation.

[0046] Step (2), first clean the surface of the scraper fineness meter and place it stably, pour the epoxy resin numbered 1 with a mass percentage of carbon nanotubes of 1% into the bottom of the groove of the scraper fineness meter. The specification of the scraper fineness meter is 0-100μm.

[0047] Step (3), the two-handed scraper blade is pressed longitudinally to the groove of the scraper fineness meter at an an...

Embodiment 2

[0052] Step (1) to step (6) are the same as in Example 1.

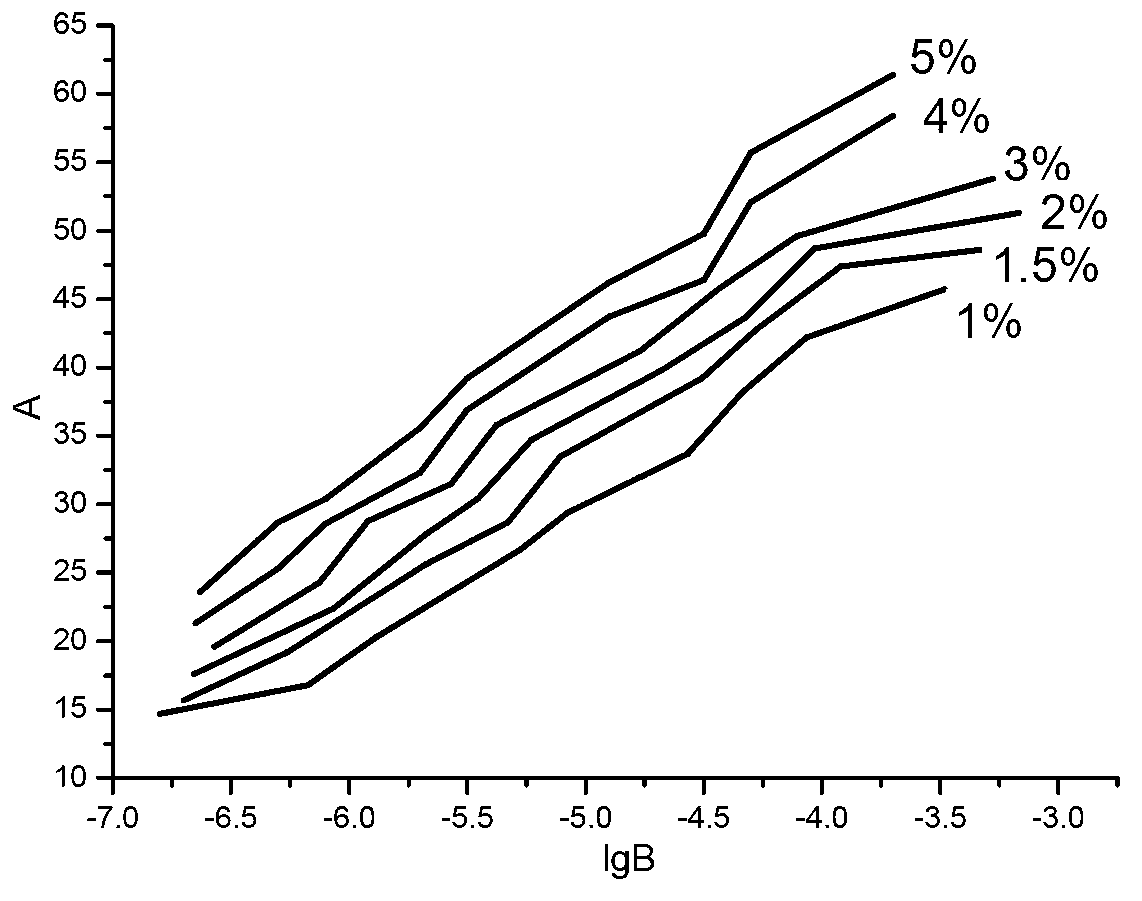

[0053] Step (7), change the mass percentage of carbon nanotubes in the epoxy resin to be tested to 1.5%, 2%, 3%, 4%, and 5%, repeat steps (1) to (5), and measure A series of data of fineness A and dispersibility B, obtain the relationship curve of fineness A changing with dispersibility B when the content of carbon nanotubes in a group of epoxy resins to be tested is different (comprising 1 in embodiment 1, altogether 6 curves). Such as image 3 Shown is a set of relationship curves in which the fineness A varies with the dispersion B in Example 2 of the present invention.

[0054] In practical applications, for example, given the epoxy resin to be tested with a carbon nanotube content of 3%, follow the above steps (1) to (3) to first measure the fineness A of the epoxy resin 2 , and then find a curve corresponding to an epoxy resin with a carbon nanotube content of 3% from the relationship curve in step (7), and o...

Embodiment 3

[0056] Step (1), using different methods to prepare vinyl ester resins with a mass percentage of carbon nanotubes of 3%, including mechanical stirring, ultrasonic dispersion, and shear dispersion, wherein three different methods of mechanical stirring, ultrasonic dispersion, and shear dispersion In the method, the process conditions were changed respectively, and a total of six kinds of vinyl ester resins with a mass percentage of carbon nanotubes of 3% were prepared as the resins to be tested, numbered 1-6. Wherein the carbon nanotubes are multi-walled carbon nanotubes modified by hydroxylation.

[0057] Step (2), first clean the surface of the scraper fineness meter and place it stably, and pour the vinyl ester resin numbered 1 with a carbon nanotube mass percentage of 3% into the bottom of the groove of the scraper fineness meter. The specification of the scraper fineness meter is 0-150μm.

[0058] Step (3), the two-handed scraper blade is pressed longitudinally against th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com