Dynamic error vision measurement method for five-axis numerical control machine tool

A CNC machine tool and visual measurement technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems that the simultaneous measurement of machine tools cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

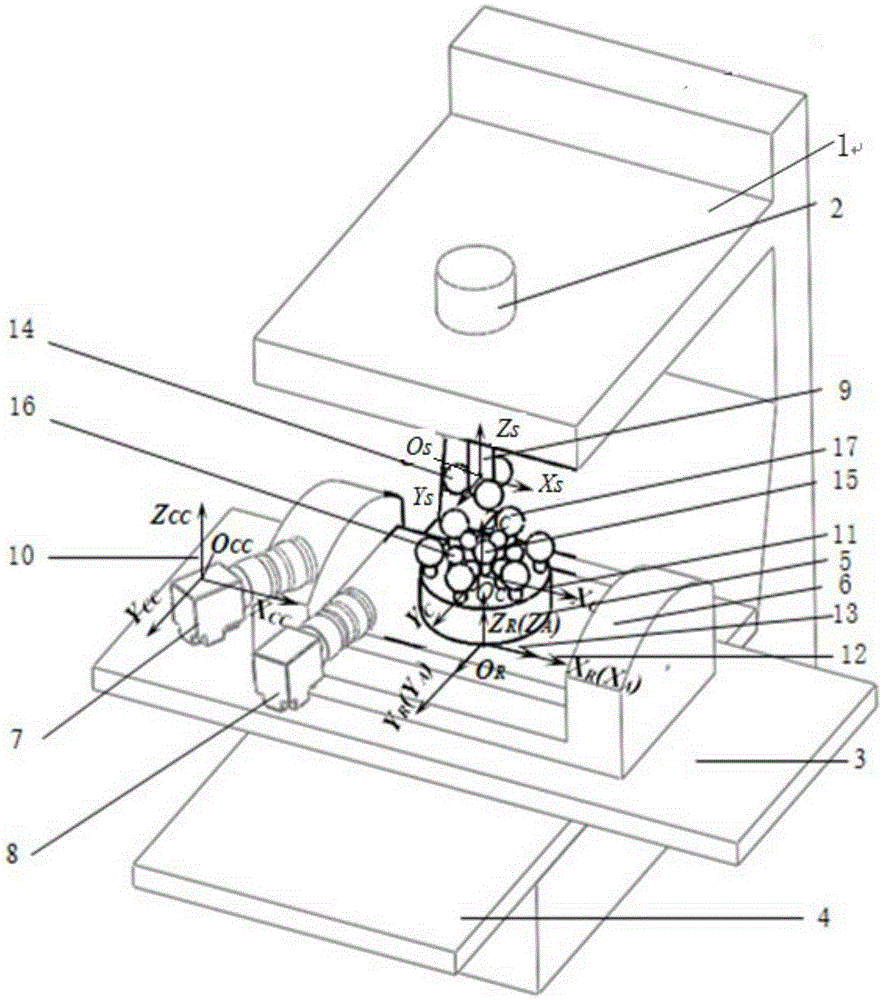

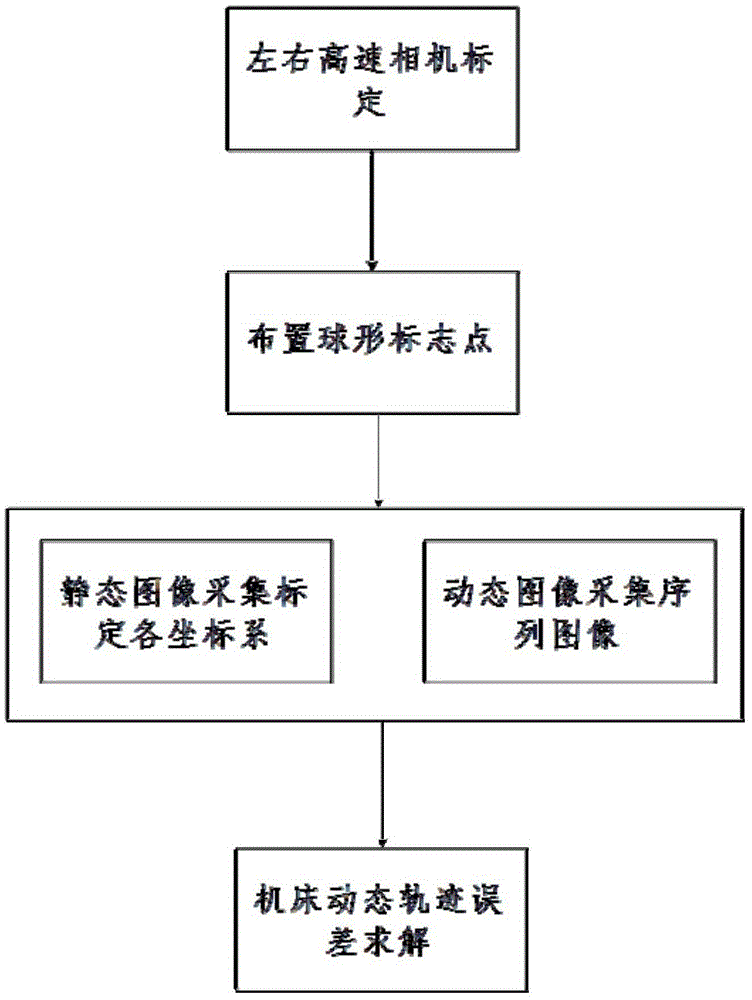

[0039] The following combined technical solutions and attached figure 1 and 2 Specific embodiments of the present invention will be described in detail.

[0040] attached figure 1 It is a schematic diagram of the visual measurement of the high-speed dynamic space trajectory error of the five-axis linkage CNC machine tool. The moving parts on the five-axis CNC machine tool 1 are composed of a machine tool spindle part 2, a machine tool X-axis part 3, a machine tool Y-axis part 4, a machine tool C-axis part 5, and a machine tool A-axis part 6; the machine tool spindle part 2 is a moving part , located on the Z-axis of the machine tool; the X-axis part 3 of the machine tool and the Y-axis part 4 of the machine tool constitute the workpiece table of the machine tool as moving parts; the installation sequence from the bottom to the top of the machine bed is Y-axis part 4 of the machine tool, X-axis part 3 of the machine tool, and A-axis component 6, machine tool C-axis component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com