Method for linear directional measurement by utilizing laser in pipe jacking engineering

A technology of pipe jacking and laser, applied in measuring devices, measuring instruments, measuring angles, etc., can solve the problems of high work intensity, higher and higher accuracy requirements, and cumbersome instruments, achieve high construction accuracy, eliminate complex problems, etc. Difficulty in measurement and the effect of reducing measurement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

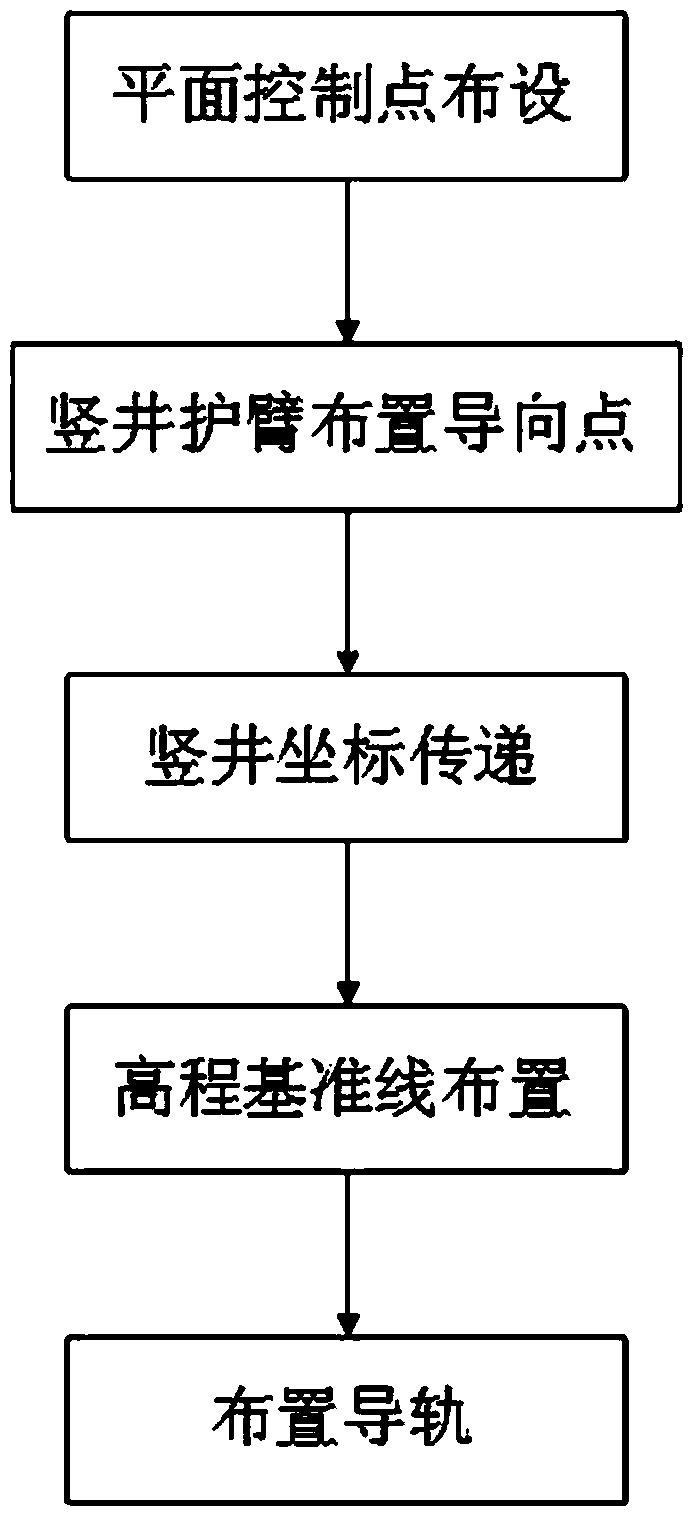

Method used

Image

Examples

example

[0094] 1. Pipe jacking project on the First Avenue of Airport New City, Xixian New District: The total length is 7.24km, which is the main line of the city and the main line of drainage facilities in the new city, with a pipe diameter of up to d3000.

[0095] 2. Fifth Avenue Municipal Project of Airport New City in Xixian New District: The total length is 6.8km, which is the main line of the city and the main line of drainage facilities in the new city.

[0096] 3. Pipe jacking project for No. 5 Road, Airport New City, Xixian New District: The maximum drainage pipeline of this road is d2600, the groundwater level is shallow, and the buried depth of the pipeline is large. The pipe jacking project is mainly used.

[0097] Verified by a number of engineering examples, the measurement method of the present invention has obtained excellent economic and social benefits:

[0098] 1. Economic benefits: The investment of measuring personnel is reduced, the measurement time is shortened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com