Method for determining void saturation of large-void asphalt mixture in seepage state

A technology for determining the method of asphalt mixture, applied in the analysis of materials, permeability / surface area analysis, suspension and porous material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

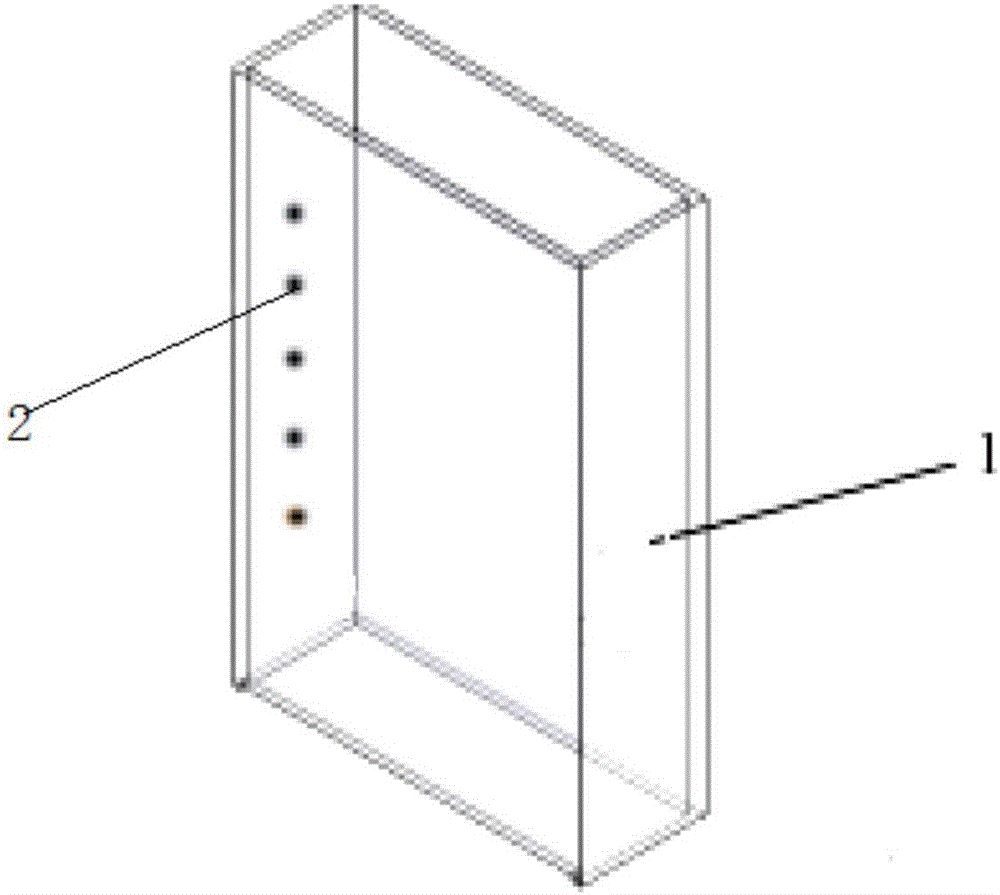

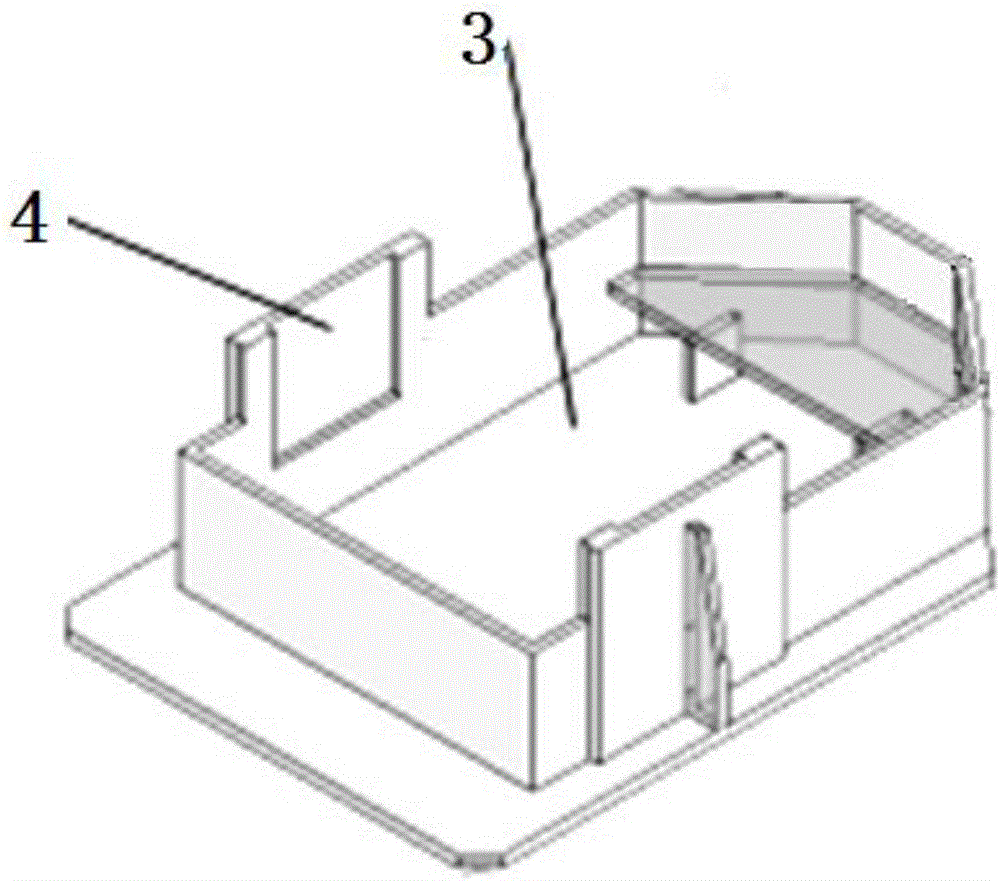

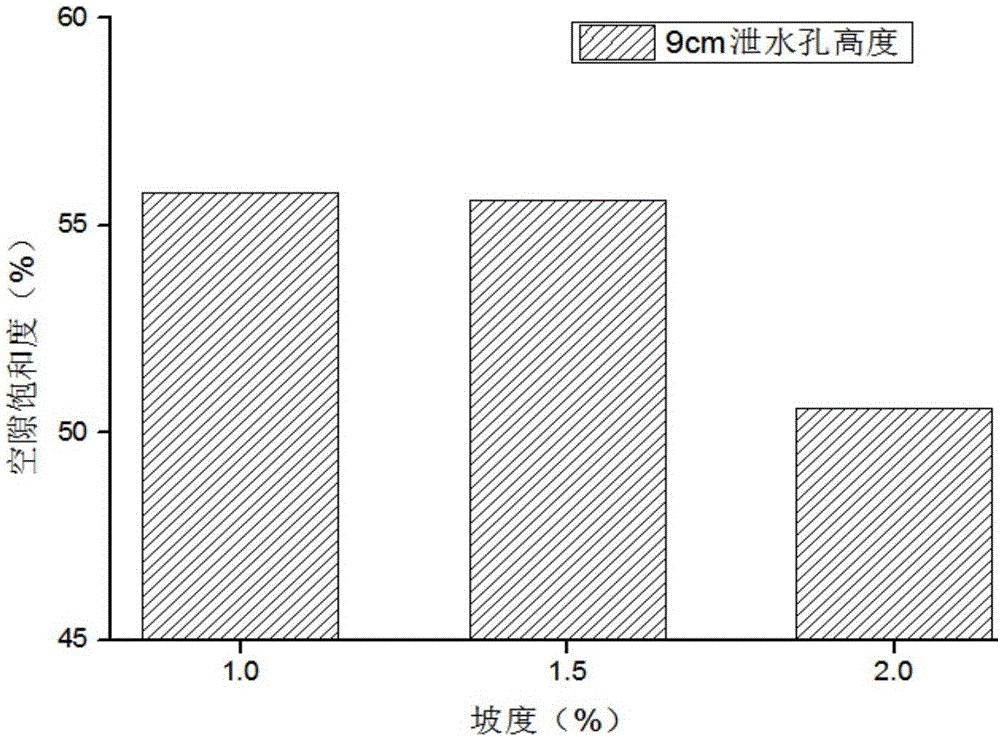

[0037] Embodiment: the determination method of void saturation of OGFC-13 composite plate type test piece, comprises the steps:

[0038] Step 1: Form the test piece and calculate the volume index.

[0039] According to the gradation shown in Table 1, when the oil-stone ratio is 4.9%, the OGFC-13 plate specimen is formed by the wheel rolling method, and the size is 300mm×300mm×60mm. The aggregate is basalt, the asphalt is high-viscosity modified asphalt, and the filler is limestone powder.

[0040] Table 1 OGFC-13 Grading

[0041] Sieve hole(mm) 16.0 13.2 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0.075 Passing rate(%) 100 92.0 66.4 28.1 16.7 13.1 10.3 7.4 6.3 4.9

[0042] For the middle position of the four sides of the formed plate-type test piece, the thicknesses measured by vernier calipers are 58mm, 63mm, 59mm and 60mm respectively, and their average value of 60mm is taken as the thickness of the test piece, and the volume V of the test piece ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com