Beam pumping unit indicator diagram soft measurement method based on neural network

A technology of beam pumping unit and neural network is applied in the field of dynamometer measurement of the beam pumping unit, which can solve the problems of wasting energy, affecting oil production, troublesome measurement process, etc., and achieving the effect of simple measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

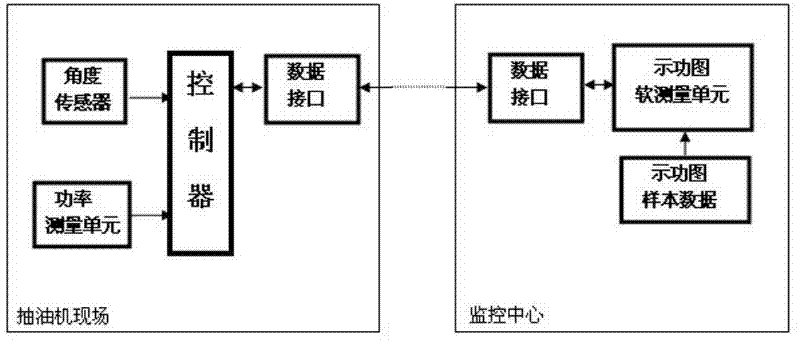

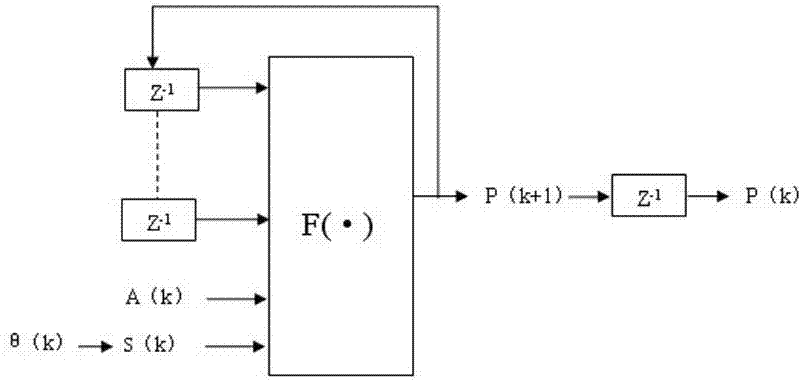

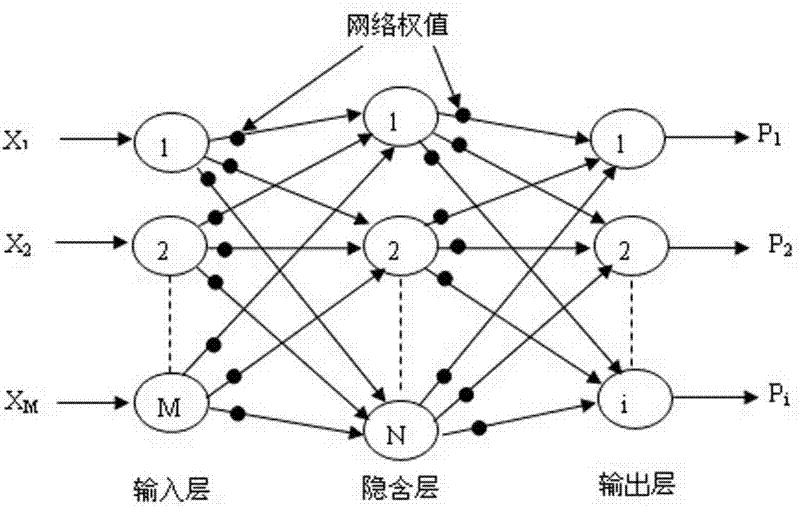

[0018] A neural network-based dynamometer soft-measurement method for a beam pumping unit is composed of an on-site data acquisition device and a neural network dynamometer measurement part of a monitoring center. The on-site data acquisition device includes an angle sensor device, a power measurement unit, a controller, and a data interface. The angle sensor is used to measure the swing angle of the beam, and the angle sensor device can use a patented product (patent: ZL 2007 2 0015325.2); the power measurement unit is used to measure the motor power; the controller completes data collection and calculation; the core of the controller can use a DSP chip Or PLC device; the data interface is used to exchange data between devices. The neural network dynamometer measurement part of the monitoring center includes data interface, dynamometer sample data and dynamometer soft measurement unit. The sample data of the dynamometer diagram is used for neural network learning; the data i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com