Production method and production system of low-volatile vinyl silicone oil

A technology of vinyl silicone oil and production method, which is applied in the field of production method and production system implementing the method, can solve the problems of limited application and expensive equipment, and achieve the effects of convenient procurement, short production cycle and wide application viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

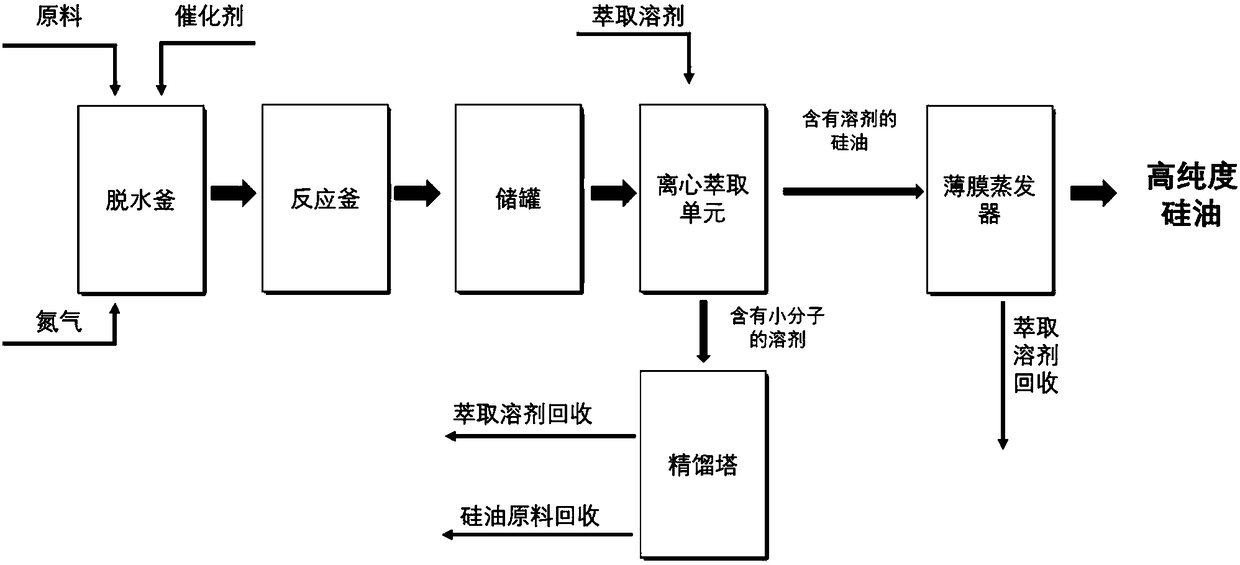

[0025] Such as figure 1 The production system of a low-volatility vinyl silicone oil shown starts from the dehydration kettle, which is connected to the reaction kettle, the storage tank, and the centrifugal extraction unit in sequence. The two-phase outlets of the centrifugal extraction unit are respectively connected to the thin film evaporator and the rectification tower.

[0026] The centrifugal extraction unit is composed of three centrifugal extraction machines in series, and the silicone oil feed and solvent feed are realized by metering pumps and the feeding speed is controlled.

[0027] The production method of low volatile vinyl silicone oil is as follows:

[0028] Add octamethylcyclotetrasiloxane and tetramethyldivinyldisiloxane to the dehydration kettle at a mass ratio of 290:1, remove water under reduced pressure and nitrogen gas, and then add catalyst tetramethylhydroxide For ammonium alkali gel, the ratio of the catalyst mass to the total mass of the material i...

Embodiment 2

[0035] Such as figure 1 The production system of a low-volatility vinyl silicone oil shown starts from the dehydration kettle, which is connected to the reaction kettle, the storage tank, and the centrifugal extraction unit in sequence. The two-phase outlets of the centrifugal extraction unit are respectively connected to the thin film evaporator and the rectification tower.

[0036] Wherein the centrifugal extraction unit is composed of 4 centrifugal extraction machines connected in series, and the silicone oil feed and the solvent feed are realized by a metering pump (not shown in the figure) and the feeding speed is controlled.

[0037] The production method of low volatile vinyl silicone oil is as follows:

[0038]Add octamethylcyclotetrasiloxane and tetramethyldivinyldisiloxane to the dehydration kettle at a mass ratio of 180:1, remove water under reduced pressure and nitrogen, and then add catalyst tetramethyl hydroxide For ammonium alkali gel, the ratio of the catalyst...

Embodiment 3

[0045] Such as figure 1 The production system of a low-volatility vinyl silicone oil shown starts from the dehydration kettle, which is connected to the reaction kettle, the storage tank, and the centrifugal extraction unit in sequence. The two-phase outlets of the centrifugal extraction unit are respectively connected to the thin film evaporator and the rectification tower.

[0046] The centrifugal extraction unit is composed of one centrifugal extraction machine connected in series, and the feeding of silicone oil and solvent is realized by a metering pump (not shown in the figure) and the feeding speed is controlled.

[0047] The production method of low volatile vinyl silicone oil is as follows:

[0048] Add octamethylcyclotetrasiloxane and tetramethyldivinyldisiloxane to the dehydration kettle at a mass ratio of 60:1, remove water under reduced pressure and nitrogen gas, and then add catalyst tetramethyl hydroxide For ammonium alkali glue, the ratio of the catalyst mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com