Polymeric reactor and polyester production method

A polymerization reaction kettle and cylinder technology, applied in the field of polyester production, can solve the problems of low devolatilization efficiency, small film forming area, poor fluidity, etc., achieve high devolatilization efficiency, fast polymerization reaction speed, and increase polymerization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

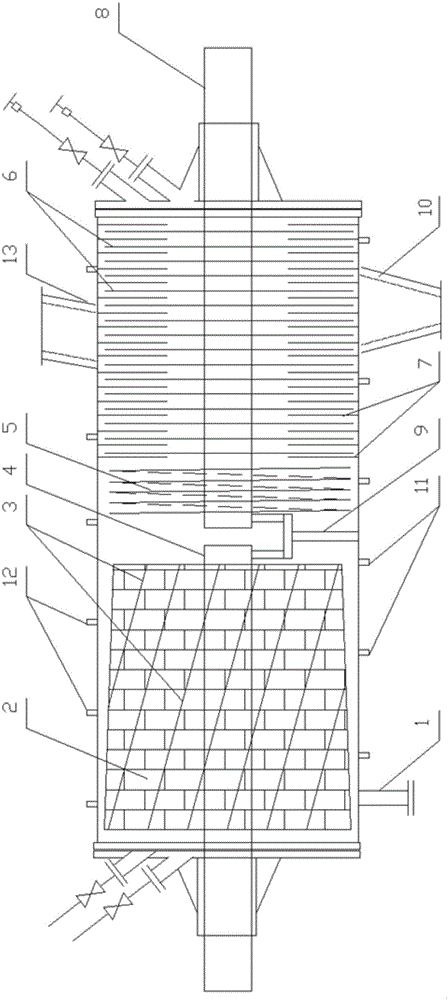

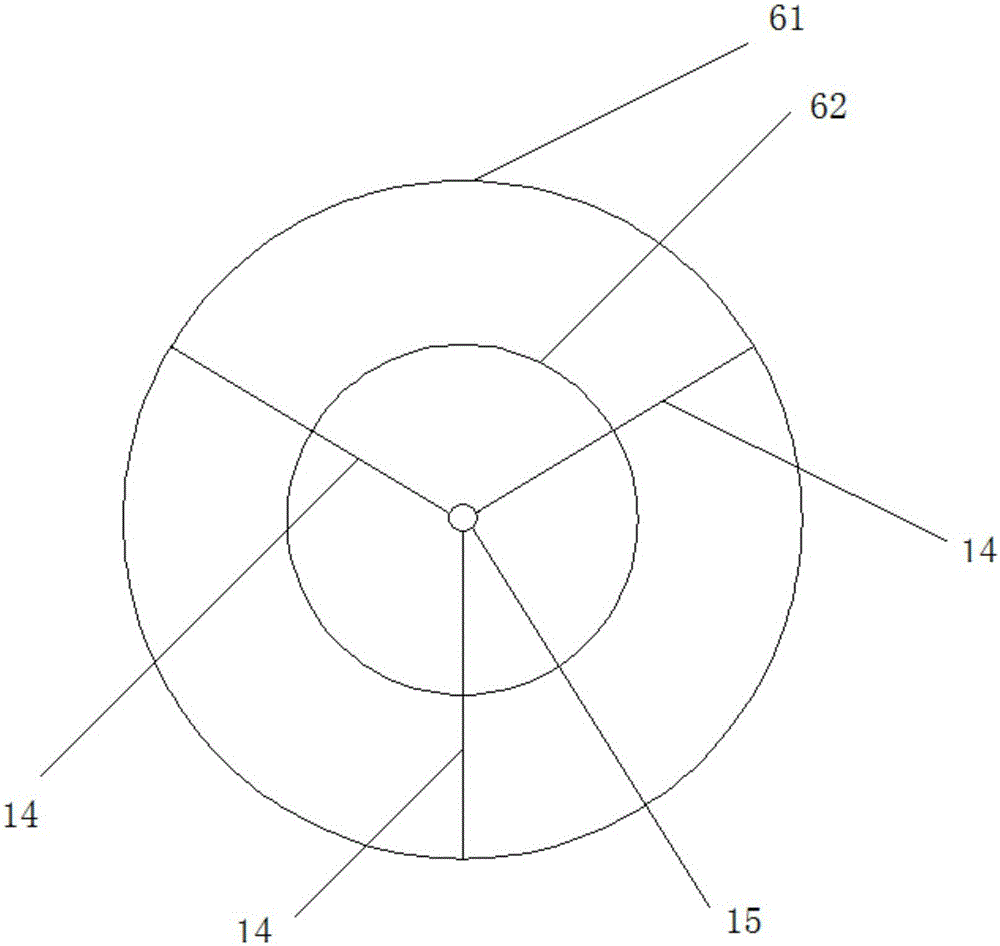

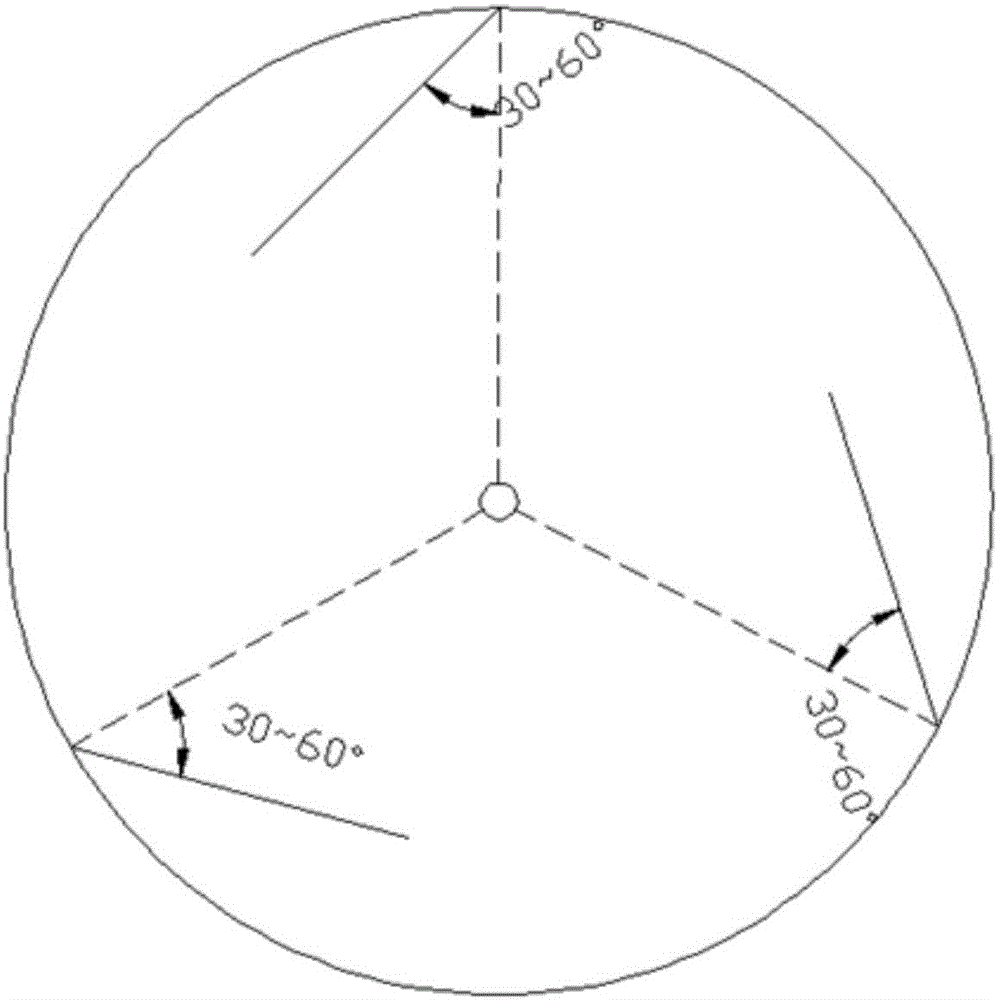

[0036] Such as figure 1As shown, a kind of polymerization reactor of the present invention, it comprises the horizontal cylinder body of sealing, described cylinder body one end is provided with material inlet 1, and the other end is provided with material outlet 10; Described cylinder body is provided with gas phase outlet 13 and is connected with The vacuum system is connected; the front-end shaft 4 is arranged near the material inlet in the cylinder, and one end of the front-end shaft protrudes from the cylinder and is connected with the power unit; the rear-end shaft 8 is arranged in the cylinder near the material outlet, and one end of the rear shaft is connected to the cylinder. The body protrudes and is connected with the second power unit; the front-end rotating shaft and the rear-end rotating shaft are respectively connected to the cylinder body through mechanical seals; the cylinder body is provided with a supporting structure 9 supporting the front-end rotating shaft...

Embodiment 2

[0044] A kind of method that utilizes the polymerization reactor described in embodiment 1 to carry out polyester production is as follows:

[0045] The polyester melt with an intrinsic viscosity of 0.25dL / g was continuously fed into the above polymerization reactor, and reacted for 150min at a temperature of 275°C and an absolute pressure of 400Pa to prepare a polyester melt with an intrinsic viscosity of 0.87dL / g. body.

Embodiment 3

[0047] A kind of method that utilizes the polymerization reactor described in embodiment 1 to carry out polyester production is as follows:

[0048] The polyester melt with an intrinsic viscosity of 0.40dL / g was continuously fed into the above-mentioned polymerization reactor, and reacted for 150min at a temperature of 270°C and an absolute pressure of 250Pa to prepare a polyester melt with an intrinsic viscosity of 1.0dL / g. body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com