Ultra-micro glue dispensing device and method

A dispensing device and ultra-micro-quantity technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of complicated cleaning, high price, cumbersome precise adjustment, etc., and achieve the effect of large viscosity range and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be further introduced below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

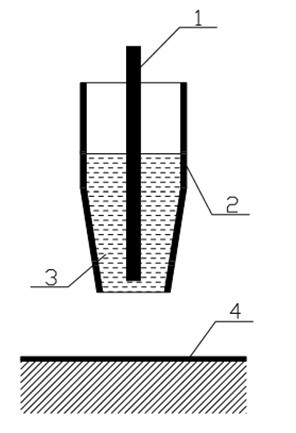

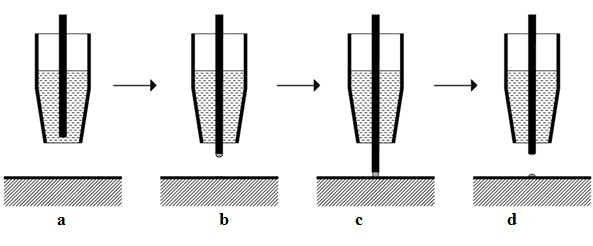

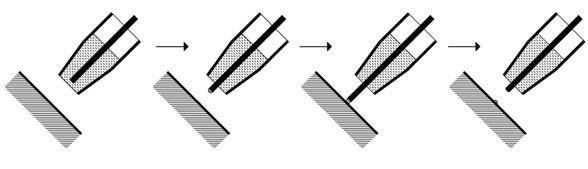

[0027] figure 1 Shown is an ultra-micro-volume dispensing device, including a pipetting needle 1, a glass microtube 2, and a glue solution 3; Insert the glue solution 3, the pipette needle 1 can move up and down through the glue solution. The tip of the glass microtube 2 is in the shape of a truncated cone, wherein the lower end is thin and the upper end is thicker, and the ratio of the thickness to the inner diameter is about 3:2, and the length of the glass microtube is about 1 cm to 2 cm. The ratio of the diameter of the pipetting needle 1 to the inner diameter of the end of the glass microtube 2 facing the dispensing surface 4 is about 1:2˜1:10. The axial centerline of the pipetting needle 1 coincides with the axial centerline of the glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com