An ultra-precise glue dispensing system and method

An ultra-precise, dispensing technology, applied to the surface coating liquid device, coating, etc., can solve the problems affecting the size and shape of the glue droplet, vibration, and affect the dispensing accuracy, etc., to improve dispensing Accuracy and stability, the effect of reducing the number of jitters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

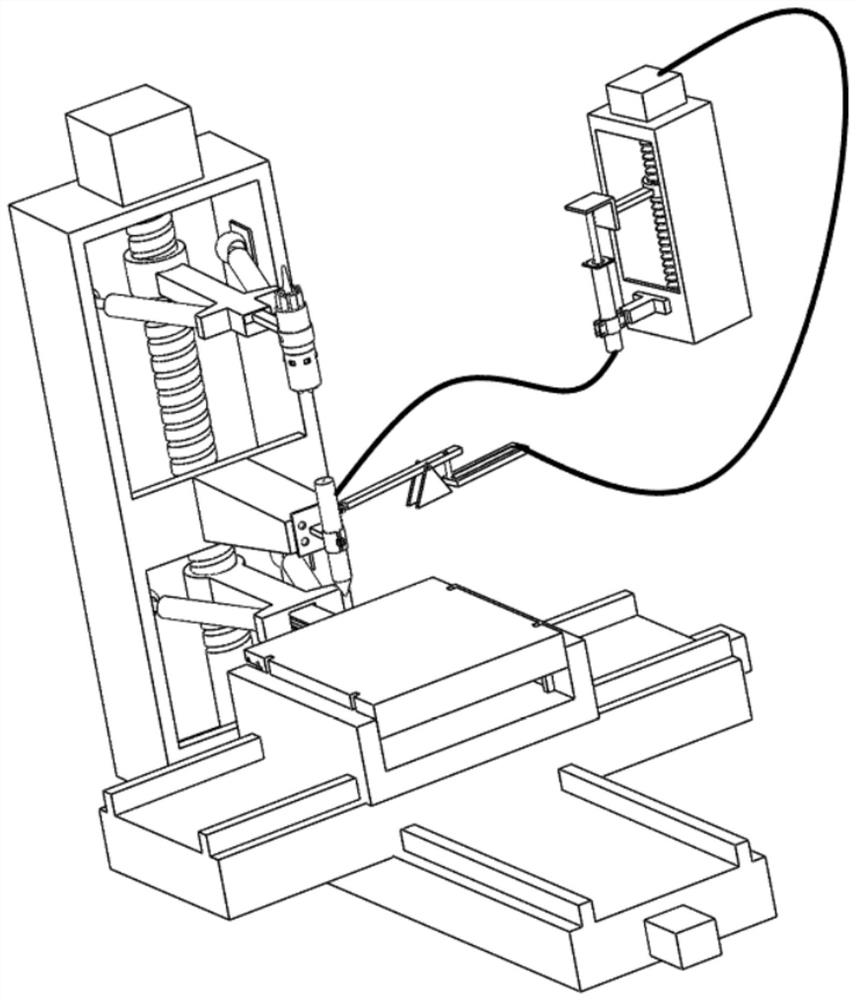

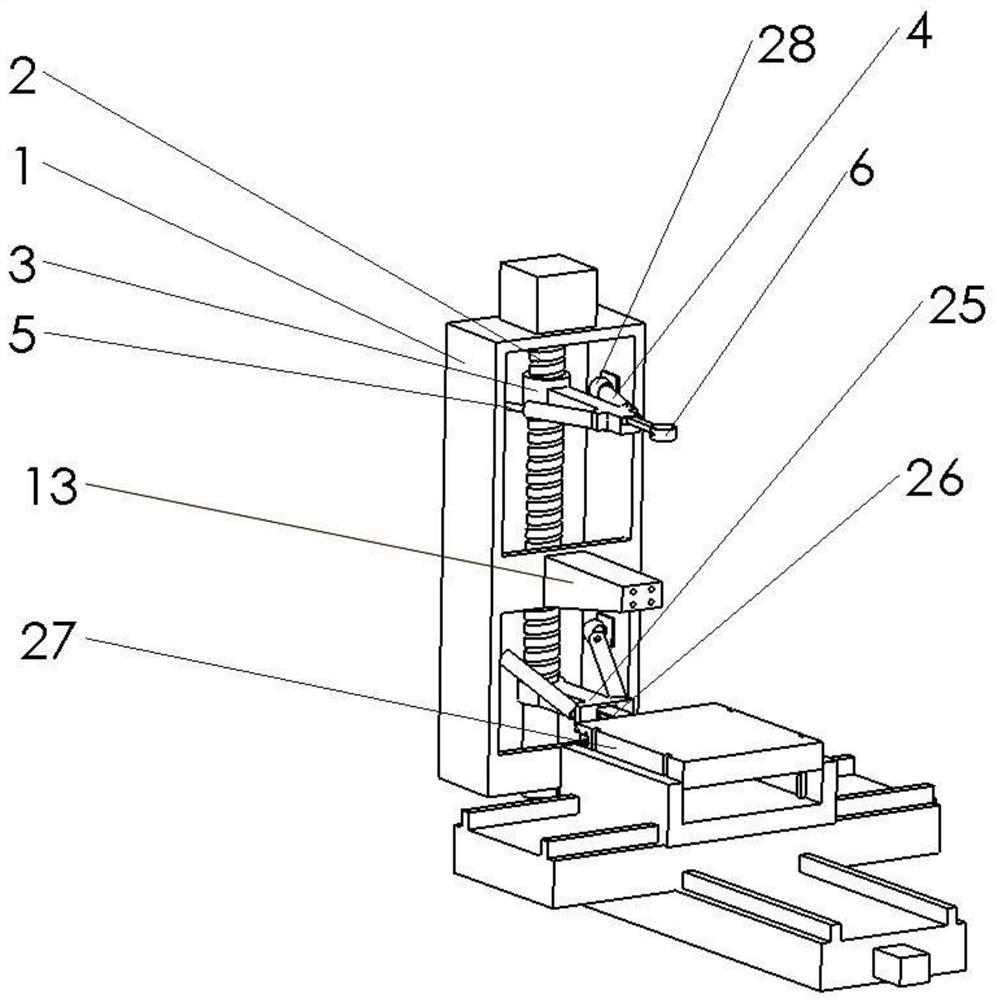

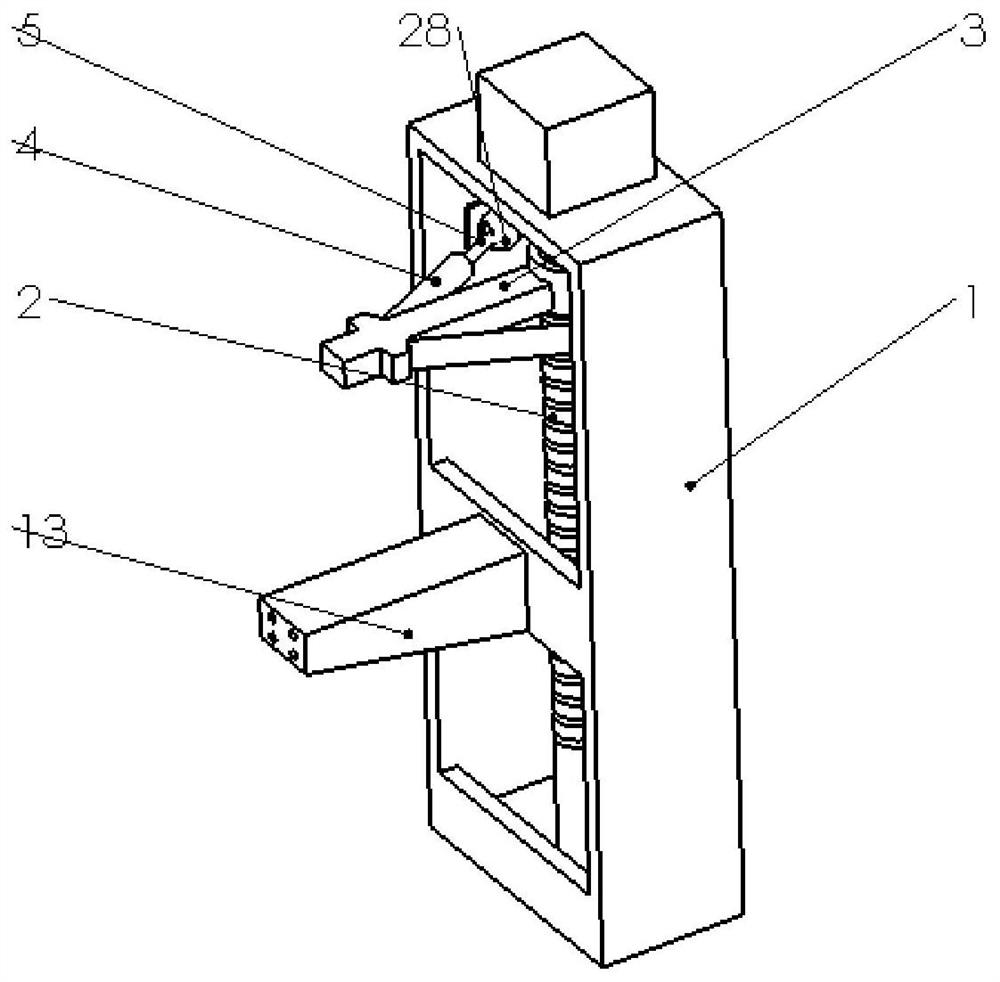

[0073] Such as figure 1 , figure 2 , image 3 As shown, an ultra-precision dispensing system, the dispensing machine is connected with the dispensing plane 27, the glue supply device is connected with the rubber storage cylinder 14; the housing 1 of the dispensing machine is provided with a motor, and the motor is connected with the The inner threaded rod 2 is connected, the screw rod 2 is installed above the threaded rod 2, the screw rod 3 is connected with the rubber syringe, several rubber needle tubes 10 are installed in the rubber syringe, and the dispensing plane installed under the threaded rod 2 The support frame 25 is connected with the dispensing plane 27 .

[0074] Such as figure 2 , image 3 As shown, the upper end of the threaded rod 2 protrudes from the housing 1 to connect with the motor, the lower end of the threaded rod 2 is in interference fit with the bearing installed under the housing 1, and the upper and lower ends of the threaded rod 2 are respecti...

Embodiment 2

[0124] Concrete structure is identical with embodiment 1, adds PLC, computer and driver simultaneously.

[0125] Input the program into the PLC through the computer, monitor the dispensing process in the computer interface, and change the GAP value by changing the initial distance between the glue needle and the dispensing surface in the program. The overall connection process is: one end of the PLC is connected to the switching power supply For power supply, the other end is connected to the driver to control the movement of the motor. The communication interface on the PLC is connected to the computer to realize the input of the program. One end of the driver is connected to the motor through a cable to convert the pulse signal sent by the PLC to the motor. Motion signal, the other end is connected to the PLC to receive the pulse signal sent by the PLC, and one end is connected to the power supply to provide power for the driver. The PLC can control the movement of the dispen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com