Base fluid for biomass drilling fluid, and preparation method and application thereof

A base fluid and drilling fluid technology, applied in the field of oil drilling, can solve the problems of biodegradability and environmental friendliness to be improved, and achieve the effects of good ecological safety and compatibility, wide viscosity range and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Correspondingly, the present invention provides a kind of preparation method of biomass drilling fluid base fluid, comprising:

[0044] In parts by weight, 60-90 parts of amino acid alcohol ester, 5-30 parts of polyetheramino alkyl glycoside and 5-10 parts of methyl silicone oil are mixed to obtain the base fluid of biomass drilling fluid.

[0045] In the embodiment of the present invention, add 60-90 parts of amino acid alcohol ester into a stirring tank with a heating device, control the temperature and stirring speed, and add 5-30 parts of polyetheramino alkyl glycoside, 5-10 parts of methyl silicone oil in sequence. After mixing, the base fluid for biomass drilling fluid is obtained, that is, the base fluid for biomass drilling fluid.

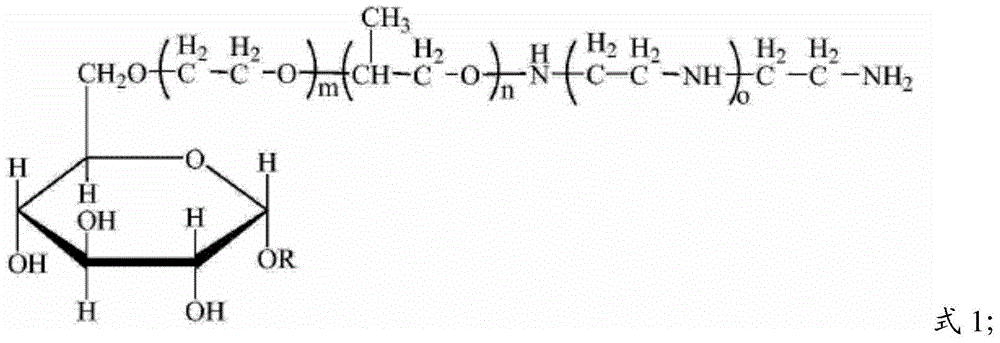

[0046] The present invention mainly adopts compound components of amino acid alcohol ester, polyether amino alkyl glycoside and methyl silicone oil to prepare biomass synthesis-based drilling fluid base fluid. The amino acid alcohol ...

Embodiment 1

[0066] In a stirring tank with a heating device, the temperature is controlled at 40°C and the stirring rate is 100r / min. In parts by weight, 60 parts of lauryl glutamate, 30 parts of polyether aminomethyl glycoside, and two 10 parts of methyl silicone oil, kept stirring for 1 hour, cooled to room temperature, and obtained biomass drilling fluid base fluid.

[0067] At a stirring speed of 8000r / min, take 100 parts by weight of the biomass drilling fluid base fluid obtained above, first add 2 parts by weight of dodecyltrimethylammonium bromide modified organic soil, stir for 5 minutes, and then add fatty acid alcohol poly 4 parts by weight of oxyethylene ether ammonium sulfate, stirred for 5 minutes, then sequentially added 3 parts by weight of organic modified humic acid amide and 2 parts by weight of quicklime, stirred for 5 minutes, and finally added 50 parts by weight of barite, stirred for 5 minutes to mix, and then packed Put it into the aging tank and roll it at 90°C for...

Embodiment 2

[0069] In a stirring tank equipped with a heating device, the temperature is controlled at 100°C and the stirring rate is 300r / min. In parts by weight, 90 parts of isopropyl sarcosinate, 5 parts of polyetheraminoethyl glycoside, two 5 parts of ethyl silicone oil, kept stirring for 3 hours, cooled to room temperature, and obtained biomass drilling fluid base fluid.

[0070] At a stirring speed of 10000r / min, take 100 parts by weight of the biomass drilling fluid base fluid obtained above, first add 3 parts by weight of cetyltrimethylammonium bromide modified organic soil, stir for 10 minutes, and then add fatty amide poly 6 parts by weight of oxyethylene ether, stirred for 10 minutes, then added 5 parts by weight of sulfonated asphalt and 4 parts by weight of quicklime, stirred for 10 minutes, and finally added 70 parts by weight of barite, stirred for 10 minutes to mix, and then put into an aging tank and heated at 120°C After hot rolling for 48 hours, the emulsion fluid, that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com