Graphene sheet film linked with carbon nanotubes, method for producing same and graphene sheet capacitor using same

A graphene sheet, carbon nanotube technology, applied in nanostructure manufacturing, graphene, capacitors and other directions, can solve the problems of capacitor performance deterioration, performance deterioration, failure to make full use of large specific surface area, etc., to achieve capacitor performance improvement, The effect of improving conductivity and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] (Example 1, Comparative Examples 1 and 2)

[0130]

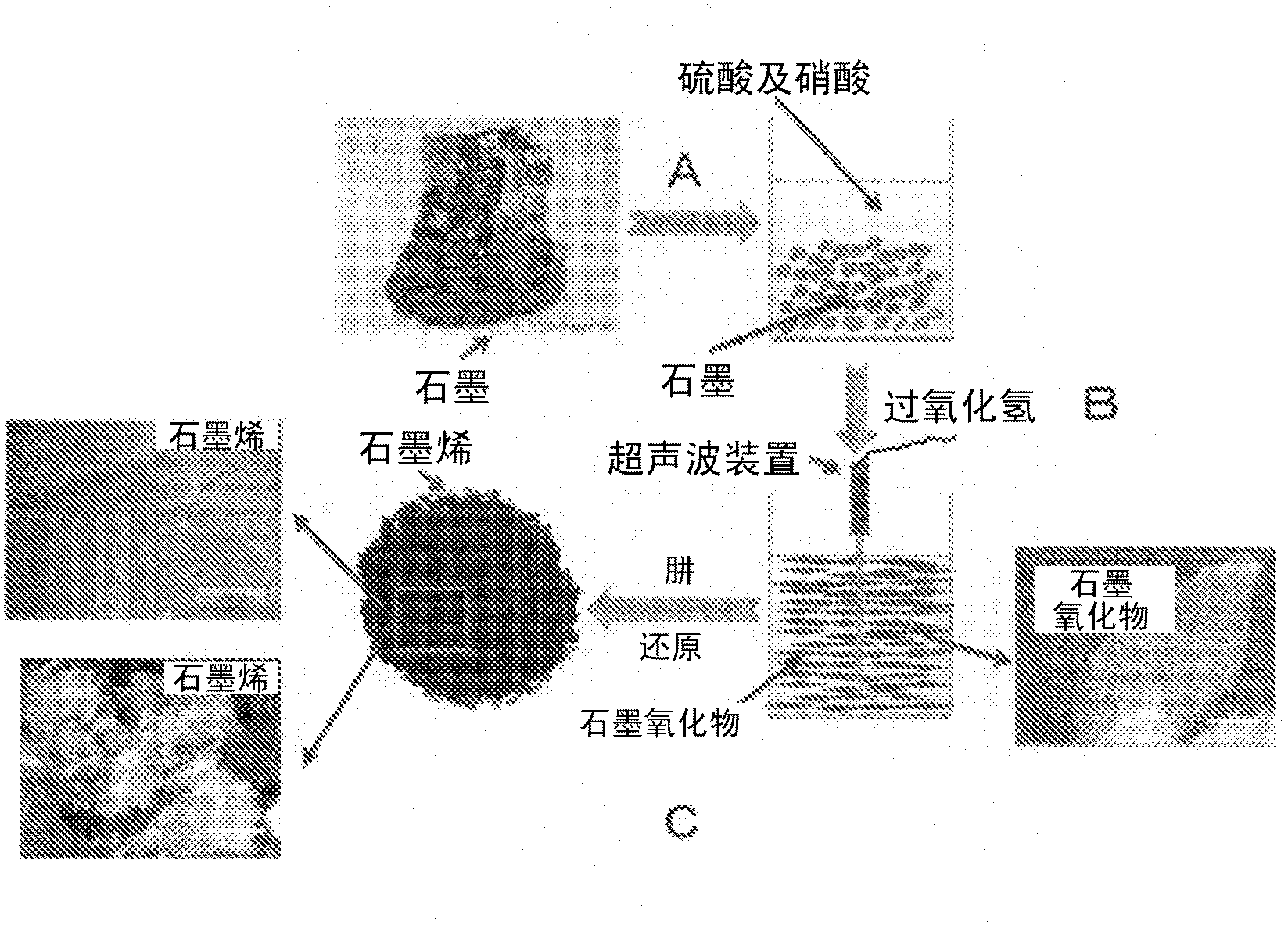

[0131] according to figure 2 The graphene generation procedure shown in , generates graphene.

[0132] First, graphite oxide was produced by the following modified Hummer's method using graphite particles as a raw material.

[0133] Specifically, first, 3 g of graphite and sodium nitrate (NaNO 3 ) 1.5g was added to the flask and mixed, then sulfuric acid (H 2 SO 4 , 95%) 100ml, stirred in an ice bath.

[0134] Then, slowly add potassium permanganate (KMnO 4 ) 8g, kept stirring at room temperature for 2 hours. At this point, the suspension gradually turned bright brown.

[0135] Next, 90 ml of distilled water was added to the flask with stirring. The temperature of the suspension rose to 90°C, and the suspension turned yellow.

[0136] Next, 30% hydrogen peroxide (H 2 o 2 ) 30ml, stirred at 98°C for 12 hours.

[0137] Next, in order to refine the product, first, rinse with 5% hydrochloric acid (HCl), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com