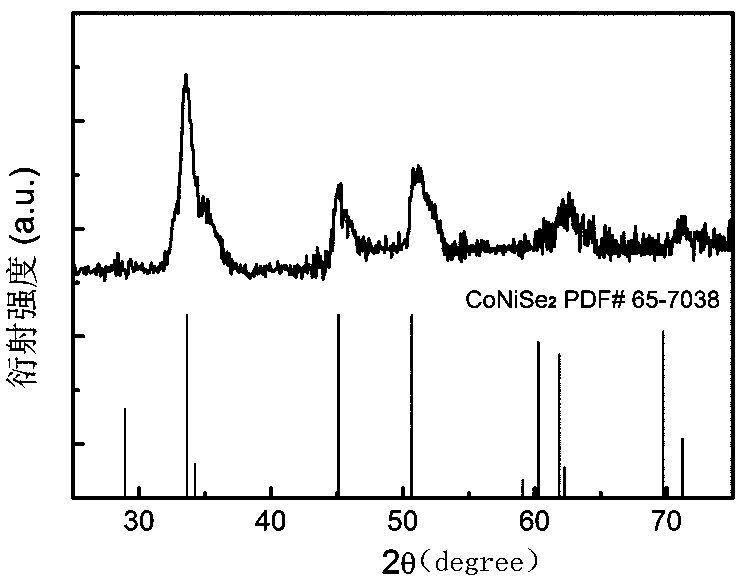

A kind of conise2 nano-array material and preparation method thereof for supercapacitor

A technology of supercapacitors and nanoarrays, applied in nanotechnology for materials and surface science, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problem of less research and application of supercapacitors, and achieve electrochemical Excellent stability, increased specific surface area, and high electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Cut the nickel foam into a size of 18mm in diameter and place it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0037] (2) Weigh 0.125mmol of nickel nitrate hexahydrate and 0.125mmol of cobalt nitrate hexahydrate as raw materials and dissolve them in 40 mL of isopropanol, then add 8mL of glycerin and stir for 30min to obtain a precursor solution.

[0038] (3) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated by (1) in it, put the reaction kettle into a drying oven, react at 180°C for 6h, and then cool Reactor to room temperature, collect foamed nickel, rinse with ethanol and deionized water respectively, and dry, the product attached to the foamed nickel is CoNiSe 2 Precursor nanospheres.

Embodiment 2

[0042] (1) Cut the nickel foam into a diameter of 18mm, and then put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0043] (2) Weigh 0.125mmol of nickel nitrate hexahydrate and 0.25mmol of cobalt nitrate hexahydrate as raw materials and dissolve them in 40mL of isopropanol, then add 8mL of glycerol and stir for 30min to obtain a precursor solution.

[0044] (3) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated by (1) in it, put the reaction kettle into a drying oven, react at 180°C for 6h, and then cool Reactor to room temperature, collect foamed nickel, rinse with ethanol and deionized water respectively, and dry, the product attached to the foamed nickel is CoNiSe 2 Precursor nanospheres.

Embodiment 3

[0048] (1) Cut the nickel foam into a diameter of 18mm, and then put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0049] (2) Weigh 0.125mmol of nickel nitrate hexahydrate and 0.125mmol of cobalt nitrate hexahydrate as raw materials and dissolve them in 40 mL of isopropanol, then add 8mL of glycerin and stir for 30min to obtain a precursor solution.

[0050] (3) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated by (1) in it, put the reaction kettle into a drying oven, react at 160°C for 6h, and then cool Reactor to room temperature, collect foamed nickel, rinse with ethanol and deionized water respectively, and dry, the product attached to the foamed nickel is CoNiSe 2 Precursor nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com