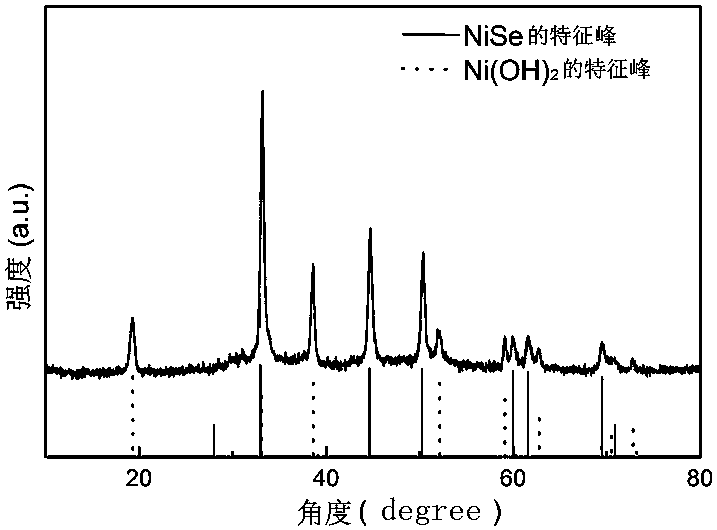

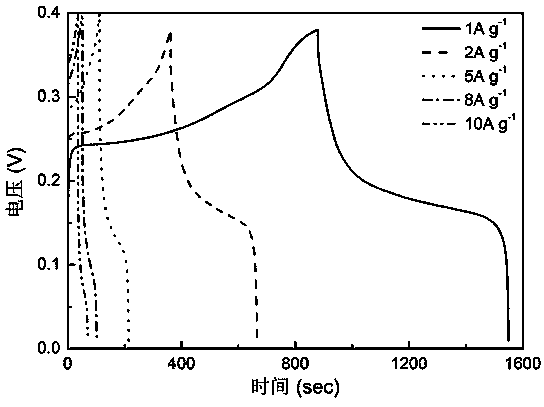

A kind of ni(oh)2/nise nanorod material and preparation method thereof for supercapacitor

A supercapacitor, nanorod technology, applied in nanotechnology for materials and surface science, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems of less research and application of supercapacitors, and achieve superior circulation Effects of stability, increased contact, high electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Cut the nickel foam into a size of 4cm×2cm and put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0038] (2) Weigh 4mmol of nickel chloride hexahydrate and 4mmol of sodium hydroxide as raw materials and dissolve them in 40mL of water, and stir for 30min to obtain a precursor solution.

[0039] (3) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated in step (1) in it, put the reaction kettle into a drying oven, and react at 180°C for 12h, then Cool the reactor to room temperature, collect the nickel foam, rinse with ethanol and deionized water, and dry.

[0040] (4) Weigh 1mmol of selenium powder and 2mmol of sodium borohydride as raw materials and dissolve them in 40mL of water, stir at room temperature for 10min, make a clear aqueous...

Embodiment 2

[0043] (1) Cut the nickel foam into a size of 4cm×2cm, and put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0044] (2) Weigh 4mmol of nickel chloride hexahydrate and 4mmol of sodium hydroxide as raw materials and dissolve them in 40mL of water, and stir for 30min to obtain the precursor solution.

[0045] (3) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated in step (1) in it, put the reaction kettle into a drying oven, and react at 160°C for 12h, then Cool the reactor to room temperature, collect the nickel foam, rinse with ethanol and deionized water, and dry.

[0046] (4) Weigh 1mmol of selenium powder and 2mmol of sodium borohydride as raw materials and dissolve them in 40mL of water, stir at room temperature for 10min to prepare a clear...

Embodiment 3

[0049] (1) Cut the nickel foam into a size of 4cm×2cm, and put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0050] (2) Weigh 4mmol of nickel chloride hexahydrate and 4mmol of sodium hydroxide as raw materials and dissolve them in 40mL of water, and stir for 30min to obtain the precursor solution.

[0051] (3) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated by (1) in it, put the reaction kettle into a drying oven, react at 200°C for 12h, and then cool The reaction kettle was brought to room temperature, and nickel foam was collected, rinsed with ethanol and deionized water, and dried.

[0052] (4) Weigh 1mmol of selenium powder and 2mmol of sodium borohydride as raw materials and dissolve them in 40mL of water, stir at room temperature for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com