Method for preparing Ni3Se4 nanowire for supercapacitor

A technology of supercapacitors and nanowires, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of less application of supercapacitors, and achieve the effects of controllable morphology, mild conditions and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

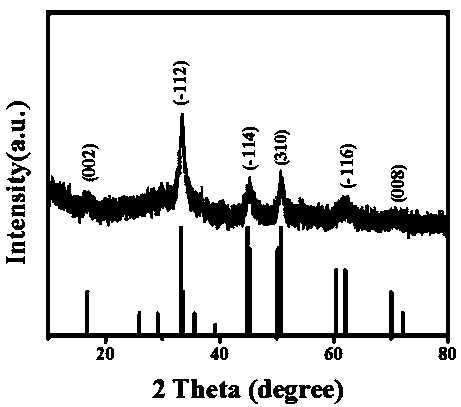

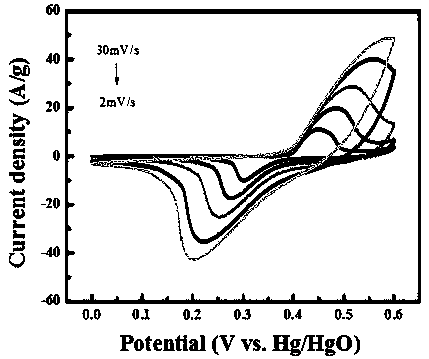

[0031] Ni for a supercapacitor 3 Se 4 Preparation of nanowires:

[0032] (1) Weigh 2.576 g of nickel sulfate hexahydrate and dissolve it in 40.0 mL of distilled water, then add 0.196 g of sodium hydroxide and stir for 30 min to obtain a reaction mixture;

[0033] (2) Transfer the reaction mixture obtained in step 1 into a polytetrafluoroethylene liner and seal it in a stainless steel reactor for solvothermal reaction. The reaction temperature is 120°C and the reaction time is 24 h. After the reaction is completed, naturally cool to room temperature. Centrifuge, wash the precipitate with water and ethanol in turn, and dry the precipitate in vacuum at 60°C to obtain nickel hydroxide nanowire powder;

[0034] (3) Under ultrasonic conditions, 200 mg of nickel hydroxide nanowires were dispersed in 25.0 mL of ethanol, and the resulting dispersion was designated as liquid A;

[0035] (4) Weigh 0.34 g of selenium powder and 0.34 g of sodium borohydride, add 5.0 mL of water, and sti...

Embodiment 2

[0037] The difference between Example 2 and Example 1 lies in that the temperature of the hydrothermal reaction in step 4 is 120° C., and the reaction time is 6 hours. All the other reaction processes are the same.

Embodiment 3

[0039] The difference between Example 3 and Example 1 is that in Step 4, the precipitate was dried in a vacuum oven at 50° C. for 12 h. All the other reaction processes are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com