Co-FPOH microsphere material for aqueous zinc-air battery and preparation method thereof

A technology of air cells and microspheres, which can be applied to fuel cell type half cells and secondary cell type half cells, battery electrodes, circuits, etc., and can solve the problems of less research and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix 50 wt.% phytic acid and deionized water and stir for 20 min to obtain the water phase, wherein the ratio of phytic acid and deionized water is 0.60 ml : 40 ml;

[0038] (2) Mix cobalt stearate, iron stearate and toluene, and prepare a uniformly dispersed toluene solution at room temperature for over 240 minutes, which is the oil phase. The ratio of cobalt stearate, iron stearate and toluene is 0.8mmol: 1.6 mmol: 40mL;

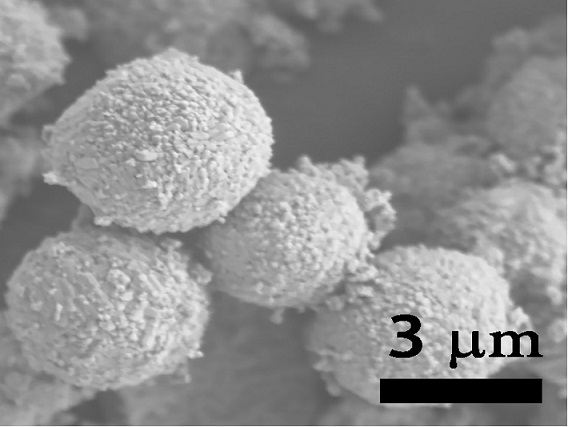

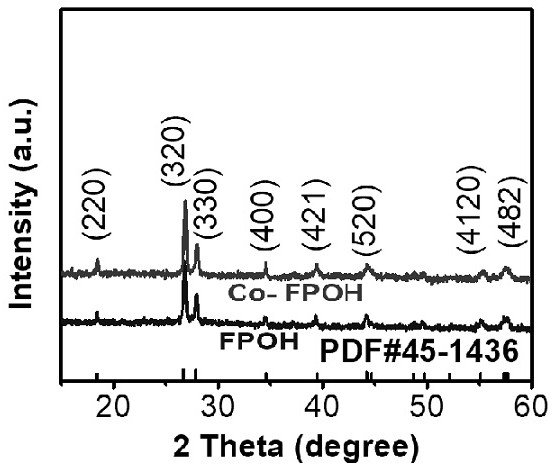

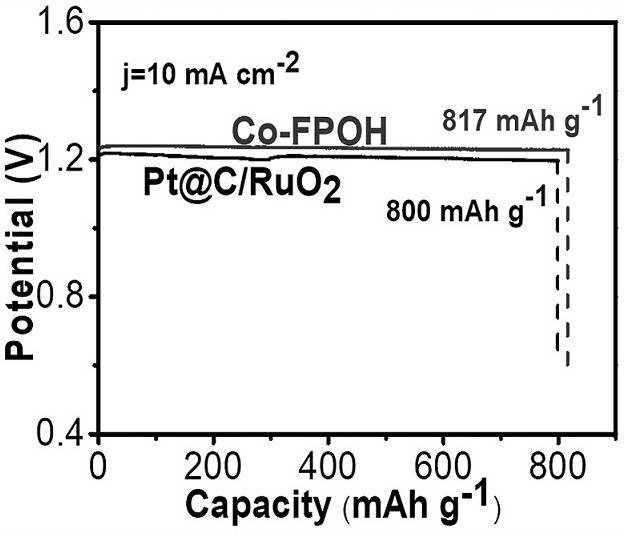

[0039] (3) First transfer the water phase obtained in step (1) to the reactor, and then transfer the oil phase obtained in step (2) to the reactor for two-phase hydrothermal reaction of water and oil at a reaction temperature of 120 ℃ for 24 hours, cooled to room temperature, collected the final product that sank to the bottom of the water, washed with deionized water and ethanol for 3 to 5 times, dried, and ground to obtain the Co-FPOH microsphere water-based zinc-air battery material, namely Co doped Fe 5 (PO 4 ) 4 (OH) 3 •H 2 O.

[0040...

Embodiment 2

[0043] (1) Mix 50 wt.% phytic acid and deionized water and stir for 20 min to obtain the water phase, wherein the ratio of phytic acid and deionized water is 0.60 ml : 40 ml;

[0044] (2) Mix cobalt stearate, iron stearate and toluene, and prepare a uniformly dispersed toluene solution at room temperature for over 240 minutes, which is the oil phase. The ratio of cobalt stearate, iron stearate and toluene is 0.8mmol: 1.6 mmol: 40mL;

[0045] (3) First transfer the water phase obtained in step (1) to the reactor, and then transfer the oil phase obtained in step (2) to the reactor for two-phase hydrothermal reaction of water and oil at a reaction temperature of 160 ℃ for 24 hours, cooled to room temperature, collected the final product that sank to the bottom of the water, washed with deionized water and ethanol for 3 to 5 times, dried, and ground to obtain the Co-FPOH microsphere water-based zinc-air battery material, namely Co doped Fe 5 (PO 4 ) 4 (OH) 3 •H 2 O.

[0046...

Embodiment 3

[0049] ((1) Mix phytic acid with a mass fraction of 50 wt.% and deionized water, and stir for 20 min to obtain an aqueous phase, wherein the ratio of phytic acid to deionized water is 0.60 ml : 40 ml;

[0050] (2) Mix cobalt stearate, iron stearate and toluene, and prepare a uniformly dispersed toluene solution at room temperature for over 240 minutes, which is the oil phase. The ratio of cobalt stearate, iron stearate and toluene is 0.8mmol: 1.6 mmol: 40mL;

[0051] (3) First transfer the water phase obtained in step (1) to the reactor, then transfer the oil phase obtained in step (2) to the reactor, and carry out the water-oil two-phase hydrothermal reaction, the reaction temperature is 180 ℃ for 24 hours, cooled to room temperature, collected the final product that sank to the bottom of the water, washed with deionized water and ethanol for 3 to 5 times, dried, and ground to obtain the Co-FPOH microsphere water-based zinc-air battery material, namely Co doped Fe 5 (PO 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com