Method for preparing dispersant-free semi-conductive single-walled carbon nanotube film

A single-walled carbon nanotube and semiconducting technology, which is applied in the field of preparing semiconducting single-walled carbon nanotube films without dispersant, can solve the problems such as the influence of the purity of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

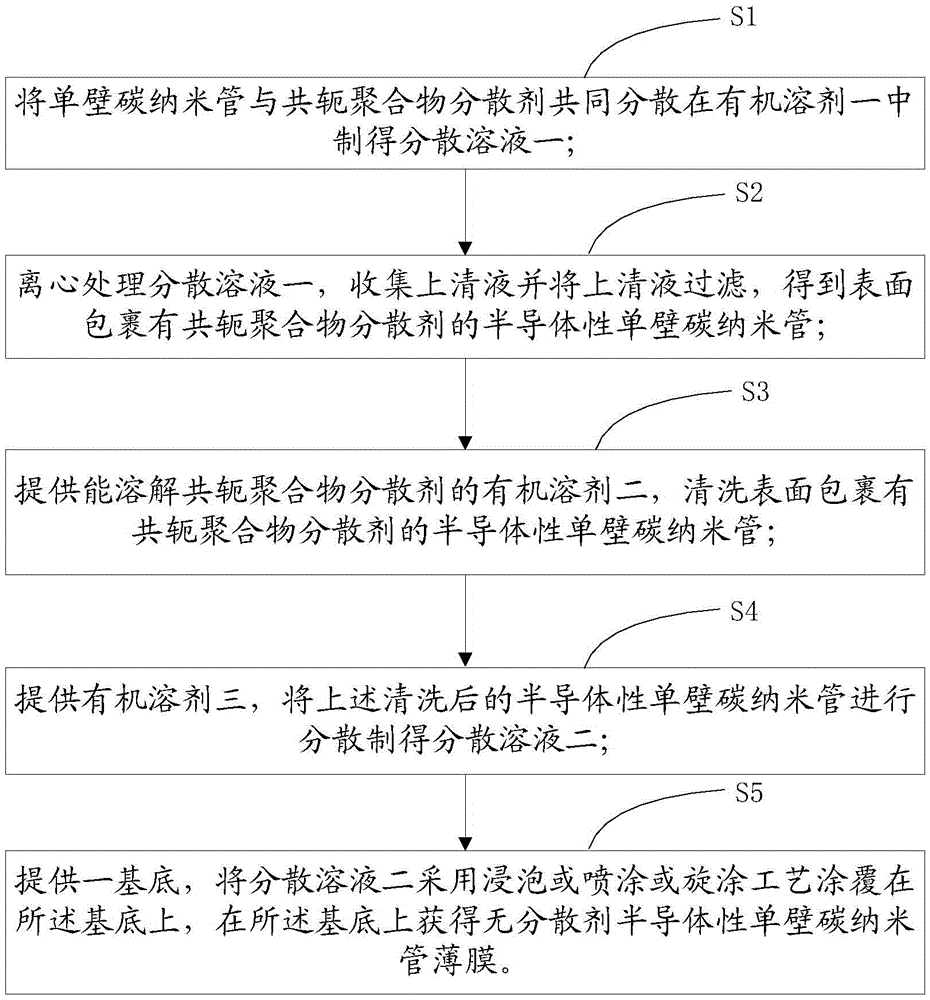

[0037] ginseng figure 1 Introduce a specific embodiment of a method for preparing a dispersant-free semiconducting single-walled carbon nanotube film of the present invention, the method specifically includes the following steps:

[0038] S1. Disperse the single-walled carbon nanotubes and the conjugated polymer dispersant in the organic solvent 1 to prepare a dispersion solution 1 . Specifically, the single-walled carbon nanotubes are single-walled carbon nanotubes grown by chemical vapor deposition, arc discharge or laser evaporation, wherein the single-walled carbon nanotubes include metallic single-walled carbon nanotubes and semiconductive single-walled carbon nanotubes. nanotubes; conjugated polymer dispersant is polycarbazole; organic solvent one is toluene or N-methylpyrrolidone (NMP). Mix single-walled carbon nanotubes, polycarbazole and toluene or N-methylpyrrolidone (NMP), and perform ultrasonic dispersion treatment. The ultrasonic power is 20W-100W, and the time i...

Embodiment 1

[0048] 1. Weigh 50 mg of conjugated polymer dispersant and 5 mg of single-walled carbon nanotubes prepared by chemical vapor deposition into a beaker, then add 100 ml of toluene to form a mixed solution;

[0049] 2. Ultrasonicize the above mixed solution, set the power to 100W, and the time is 0.5h, centrifuge after the ultrasonication is completed, set the centrifugal speed to 10000g, and the time is 20h. After the centrifugation is completed, the supernatant is collected, and the supernatant is filtered using a polytetrafluoroethylene filter membrane with a filter hole of 0.1 micron, and the semiconductive single-walled carbon nanotubes coated with a conjugated polymer dispersant remain on the filter membrane. Part of the conjugated polymer dispersant and metallic single-walled carbon nanotubes are filtered out through the filter pores;

[0050] 3. Soak the semiconducting single-walled carbon nanotubes on the filter membrane in a large amount of xylene solvent, and ultrasoni...

Embodiment 2

[0055] 1. Weigh 50mg of conjugated polymer dispersant and 100mg of single-walled carbon nanotubes prepared by arc discharge method into a beaker, then add 100ml of N-methylpyrrolidone (NMP) to make a mixed solution;

[0056] 2. Ultrasonicize the above mixed solution, set the power to 20W, and the time is 2h, centrifuge after the ultrasonication is completed, set the centrifugal speed to 1000000g, and the time is 0.5h. After the centrifugation is completed, the supernatant is collected, and the supernatant is filtered using a polytetrafluoroethylene filter membrane with a filter hole of 0.025 microns, and the semiconductive single-walled carbon nanotubes coated with a conjugated polymer dispersant remain on the filter membrane. Part of the conjugated polymer dispersant and metallic single-walled carbon nanotubes are filtered out through the filter pores;

[0057] 3. Soak the semiconducting single-walled carbon nanotubes on the filter membrane in a large amount of cyclohexane so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com