Preparation method for crosslinking type polyimide aerogel

A technology of polyimide and airgel, which is applied in the field of nanoporous material preparation, can solve the problems of high density, poor thermal stability of organic aerogels, and limited application prospects, etc., and achieve good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

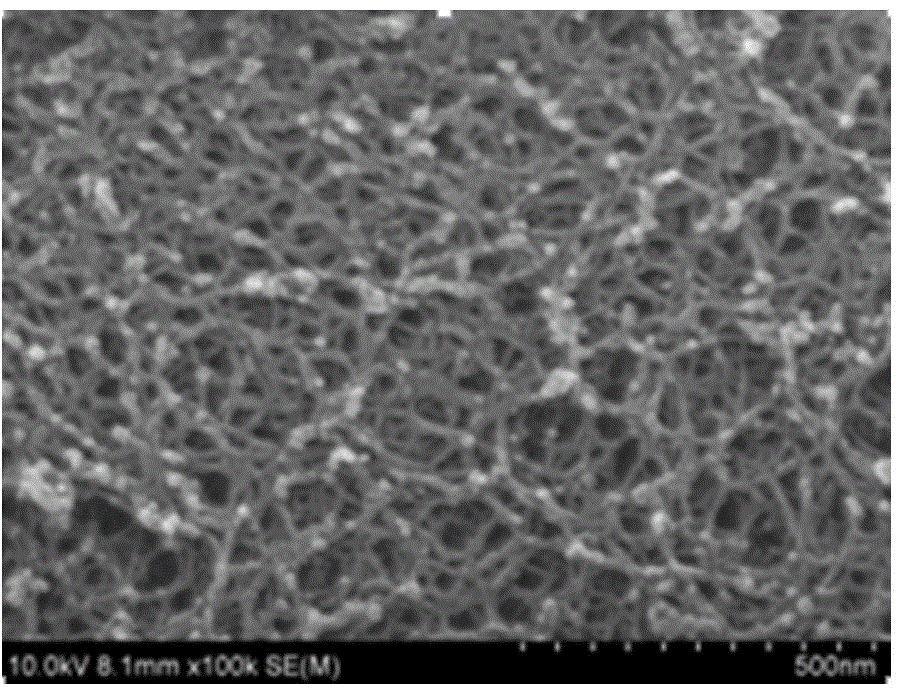

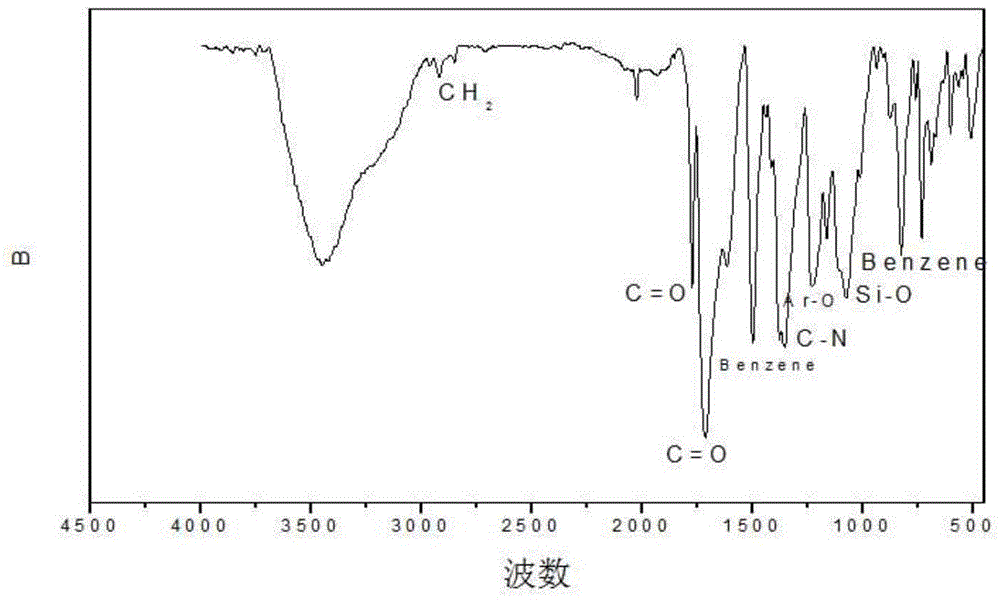

[0021] Preparation of cross-linked polyimide airgel

[0022] Diamine, dianhydride and silane coupling agent (2,2'-bis[4-(4-aminophenoxyphenyl)]propane, 3,3',4,4'-biphenyltetracarboxylic acid di Anhydride, 3-aminopropyltriethoxysilane mass ratio is 2.5:3.4:0.15) dissolved in N-methylpyrrolidone, mixed into a 48ml mixed solution, stirred rapidly, then added dehydrating agent 11.1ml (acetic anhydride, The volume ratio of pyridine is 6.5:5.6), and after rapid stirring, it gels at room temperature. After 24 hours, use pure N-methylpyrrolidone for 2 solvent replacements, with an interval of 6-10 hours each time, and then use a mixed solution of N-methylpyrrolidone and acetone for 2 solvent replacements, each time for 6-10 hours. Finally, the gel was replaced with pure acetone for 3 times of solvent, each time for 6-10h, and finally supercritical drying was carried out. The resulting density is 130mg / cm 3 , The specific surface area is 530m 2 / g of cross-linked polyimide airgel. ...

Embodiment 2

[0025] Preparation of cross-linked polyimide airgel

[0026] Diamine, dianhydride and silane coupling agent (2,2'-bis[4-(4-aminophenoxyphenyl)]propane, 3,3',4,4'-biphenyltetracarboxylic acid di Anhydride, 3-aminopropyltriethoxysilane mass ratio is 2.5:3.4:0.15) dissolved in N-methylpyrrolidone, mixed into a 35ml mixed solution, stirred rapidly, then added dehydrating agent 11.1ml (acetic anhydride, The volume ratio of pyridine is 6.5:5.6), and after rapid stirring, it gels at room temperature. After 24 hours, use pure N-methylpyrrolidone for 2 solvent replacements, with an interval of 6-10 hours each time, and then use a mixed solution of N-methylpyrrolidone and acetone for 2 solvent replacements, each time for 6-10 hours. Finally, the gel was replaced with pure acetone for 3 times of solvent, each time for 6-10h, and finally supercritical drying was carried out.

Embodiment 3

[0028] Preparation of cross-linked polyimide airgel

[0029] Diamine, dianhydride and silane coupling agent (2,2'-bis[4-(4-aminophenoxyphenyl)]propane, 3,3',4,4'-biphenyltetracarboxylic acid di Anhydride, 3-aminopropyltriethoxysilane mass ratio is 2.5:3.4:0.15) dissolved in N-methylpyrrolidone, mixed into a 70ml mixed solution, stirred rapidly, then added dehydrating agent 11.1ml (acetic anhydride, The volume ratio of pyridine is 6.5:5.6), and after rapid stirring, it gels at room temperature. After 24 hours, use pure N-methylpyrrolidone for 2 solvent replacements, with an interval of 6-10 hours each time, and then use a mixed solution of N-methylpyrrolidone and acetone for 2 solvent replacements, each time for 6-10 hours. Finally, the gel was replaced with pure acetone for 3 times of solvent, each time for 6-10h, and finally supercritical drying was carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com