Calcium phosphate composite material for filling root canal and preparation method thereof

A composite material, calcium and magnesium phosphate technology, used in dental preparations, dentistry, dental prostheses, etc., can solve the problems of difficult ingrowth of new bone, slow degradation, irregular root canal shape, etc. The effect of improving collapse resistance and promoting bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

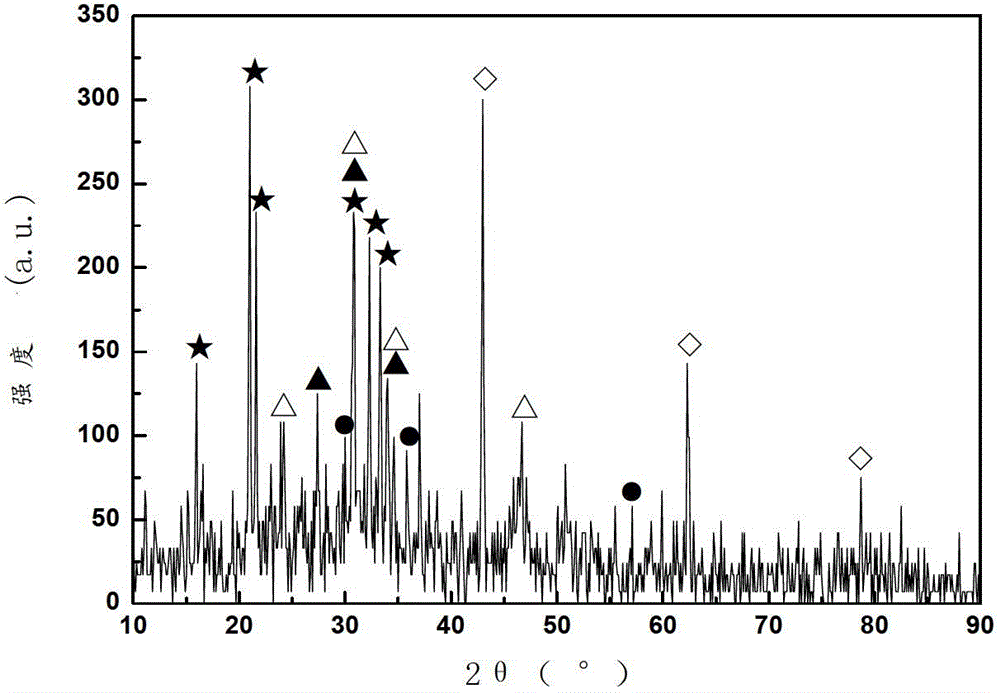

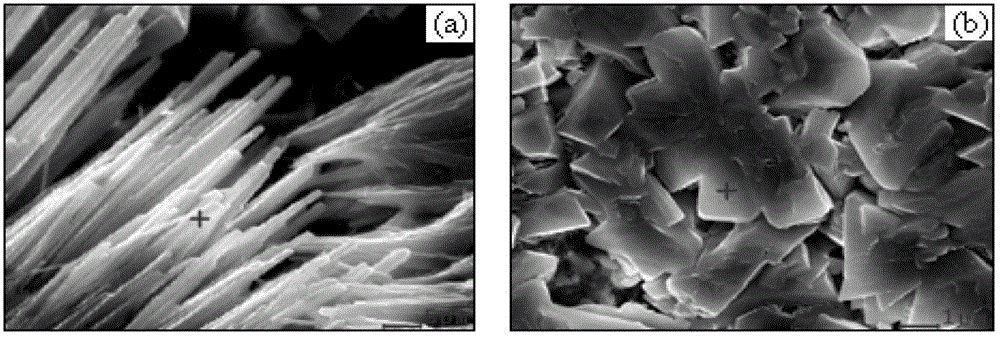

[0043] Weigh 5.0g α-tricalcium phosphate, 2.0g tetracalcium phosphate, 1.0g magnesium oxide, 1.5g potassium dihydrogen phosphate, 0.5g iodoform, the particle size is less than 20μm, and mix uniformly to form a solid phase powder. Weigh 2.0 g of sodium dihydrogen phosphate, 0.5 g of sucrose, and 0.5 g of glucose and fully dissolve them in 10 ml of 0.5 mol / L citric acid solution to obtain a solidified liquid in the liquid phase. Pour the solidification liquid into the solid phase powder at a liquid-solid ratio of 0.3ml: 1mg, and mix it evenly in a syringe to obtain a filling material.

Embodiment 2

[0045] Weigh 6.0g of α-tricalcium phosphate, 1.5g of magnesium oxide, 1.5g of potassium dihydrogen phosphate, and 1.0g of iodoform, the particle size of which is less than 20 μm, and mix them uniformly to form a solid phase powder. Weigh 1.0 g of disodium hydrogen phosphate, 1.0 g of sodium dihydrogen phosphate, and 0.8 g of glucose and fully dissolve them in 10 ml of 0.6 mol / L citric acid solution to obtain a solidified liquid in the liquid phase. Pour the solidified liquid into the solid phase powder at a liquid-solid ratio of 0.4ml: 1mg, and mix it evenly in the vessel to obtain the filling material. Example 3:

Embodiment 3

[0046] Weigh 8.0g of α-tricalcium phosphate, 1.0g of magnesium oxide, and 1.0g of iodoform, the particle size of which is less than 20μm, and mix them uniformly to form a solid phase powder. Weigh 2 g of potassium dihydrogen phosphate and 1.0 g of dextrin and fully dissolve them in 10 ml of 1.0 mol / L citric acid solution to obtain a solidified liquid in the liquid phase. Pour the solidified liquid into the solid phase powder at a liquid-solid ratio of 0.5ml: 1mg, and mix it evenly in the vessel to obtain the filling material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com