Assembly type self-resetting buckling restrained brace

A buckling restraint and self-resetting technology, which is applied in protective buildings/shelters, building components, earthquake resistance, etc., can solve the problems of high cost, large internal force and damage of connecting nodes and adjacent components, and achieve structural interlayer deformation Uniformity, improve collapse resistance, and prevent concentrated deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below with reference to the drawings and specific implementation methods.

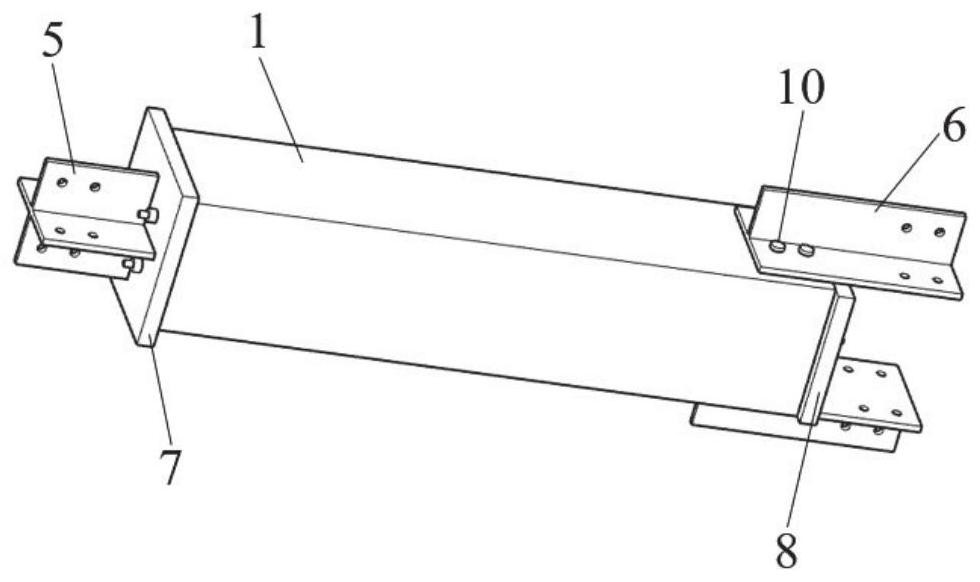

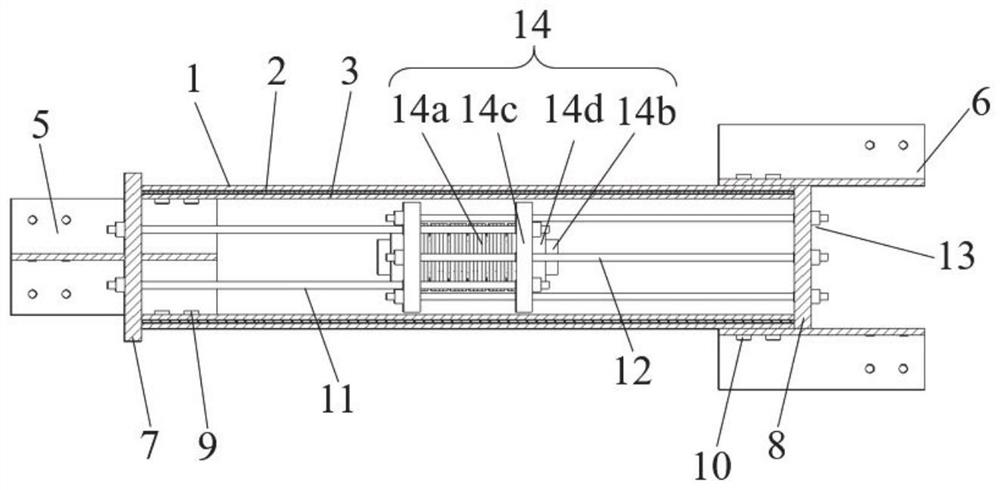

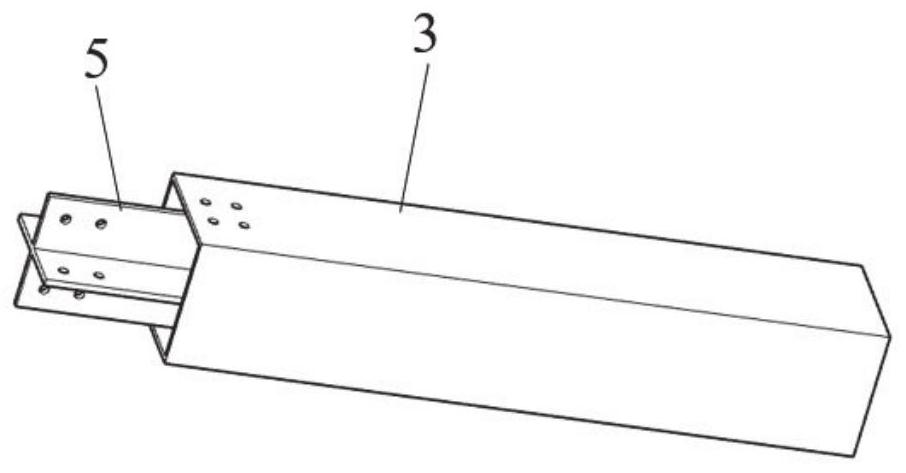

[0036] An assembled self-resetting buckling-restrained brace, such as Figure 1-9 As shown, the assembly includes an outer tube 1, an energy-dissipating inner core 2, an inner tube 3, a left connector 5, a right connector 6, a left end plate 7, a right end plate 8, the first group of prestressed steel strands 11, the first Two groups of prestressed steel strands 12 and disc spring reset device 14.

[0037] The left connecting piece 5 is connected to the inner pipe 3 by welding, and the right connecting piece 6 is connected to the outer pipe 1 by welding. The energy dissipation inner core 2 is located between the inner tube 3 and the outer tube 1 , and its left end is connected with the inner tube 3 by a self-tapping screw 9 , and its right end is connected with the outer tube 1 by a self-tapping screw 10 . The first gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com