High-strength injectable magnesium phosphate bone cement and preparation method thereof

A magnesium phosphate bone cement, high-strength technology, applied in the field of bone cement, can solve the problems of limited strength of magnesium-based bone cement, lack of biocompatibility, difficult to apply to load-bearing parts, etc., to prolong the curing time and improve the collapse resistance , the effect of rapid development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

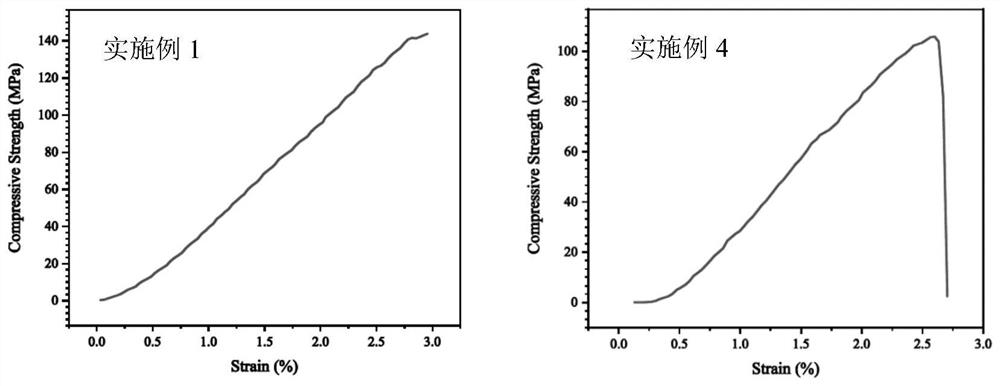

Embodiment 1

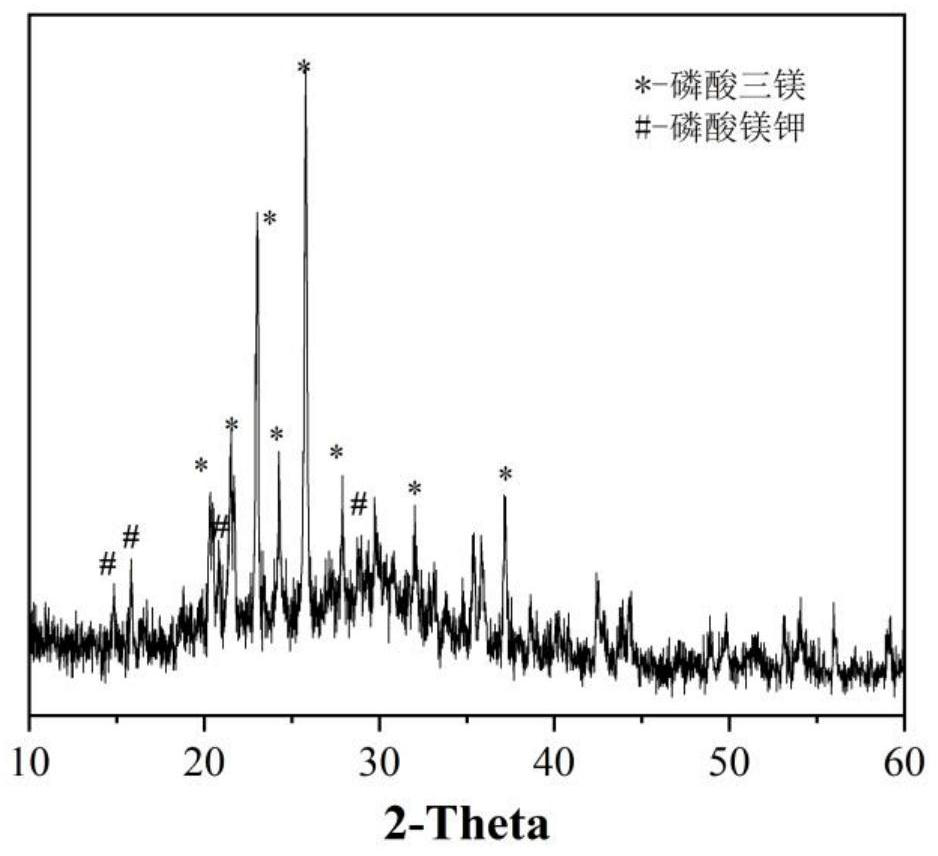

[0029] Weigh 3g of anhydrous trimagnesium phosphate powder, particle size 3-5μm, potassium dihydrogen phosphate powder 1g, particle size 5-10μm; mix solid phase and liquid phase according to the ratio of solid phase and liquid phase 3g: 1mL, and mix After the paste is transferred to the syringe for injection molding, the injectability is 99%, and the average compressive strength is 140MPa.

Embodiment 2

[0031] Weigh 3g of anhydrous trimagnesium phosphate powder, particle size 3-5μm, potassium dihydrogen phosphate powder 1g, particle size 5-10μm; mix the solid phase and liquid phase according to the ratio of solid phase and liquid phase 2.5g: 1mL, and mix The final paste is transferred to a syringe for injection molding, the injectability is 99%, and the average compressive strength is 110MPa.

Embodiment 3

[0033] Weigh 2g of anhydrous trimagnesium phosphate powder, particle size 3-5μm, potassium dihydrogen phosphate powder 1g, particle size 5-10μm; mix the solid phase and liquid phase according to the ratio of solid phase and liquid phase 3g: 1mL, and mix the The paste is transferred to the syringe for injection molding, the injectability is 99%, and the average compressive strength is 90MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com