Processing box

A technology for processing cartridges and consumables, applied in the field of processing cartridges, can solve the problems that the sealing blade 13 cannot be in close contact with the developing roller 12, the contact surface gap between the sealing blade 13 and the developing roller 12, and the sealing is not strict.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

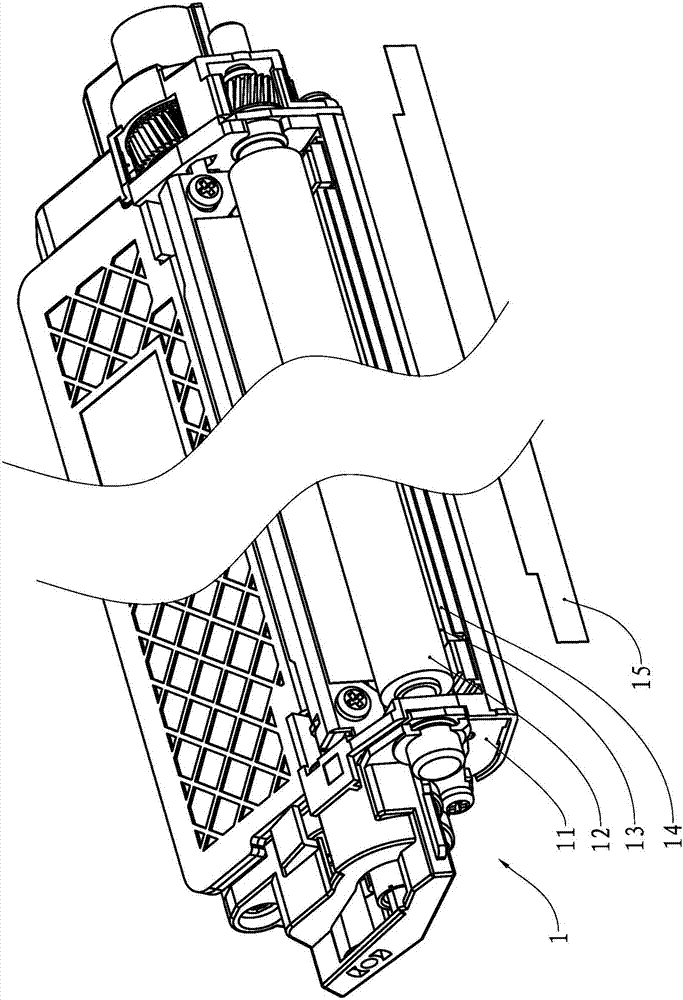

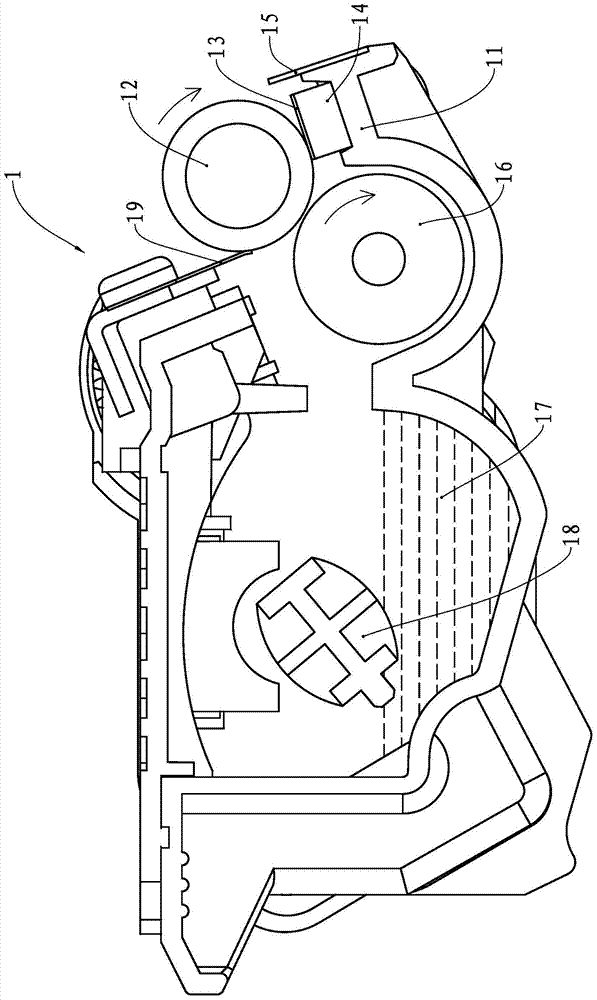

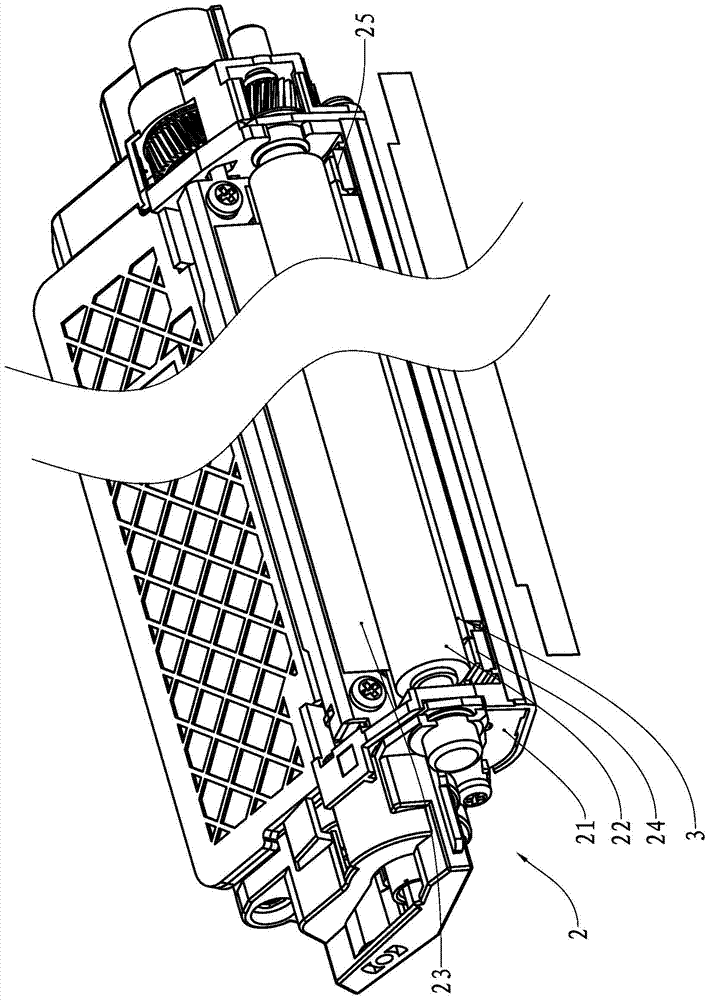

[0033] Reference image 3 , image 3 It is a structural diagram of the processing box 2 of the present invention. The processing box 2 includes a housing 21. On one end of the housing 21, a powder outlet knife 23, a sealing felt 24, a sealing felt 25, and a sealing assembly are provided. The sealing assembly includes a sealing blade 3 And seal 4 ( Figure 5 visible). The housing 21 encloses a cavity containing toner as a printing consumable. One end of the cavity is provided with a toner outlet. The toner outlet is surrounded by a powder ejection knife 23, a sealing felt 24, a sealing felt 25 and a sealing component. A developing roller 22 is installed at the toner outlet, and a sealing assembly is installed under the developing roller 22.

[0034] Reference Figure 4 , Figure 4 For the structure diagram of the sealing blade 3, the sealing blade 3 includes a fixed portion 31 and a contact portion 32. The angle formed between the fixed portion 31 and the contact portion 32 is α i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com