Crude chocolate sample composition, manufacturing method thereof and dessert using the same

A manufacturing method and chocolate technology, applied in application, food science, cocoa and other directions, can solve the problems of light gas-containing chocolate, high cost, huge labor and other problems, and achieve the effect of excellent flavor and good mouth solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

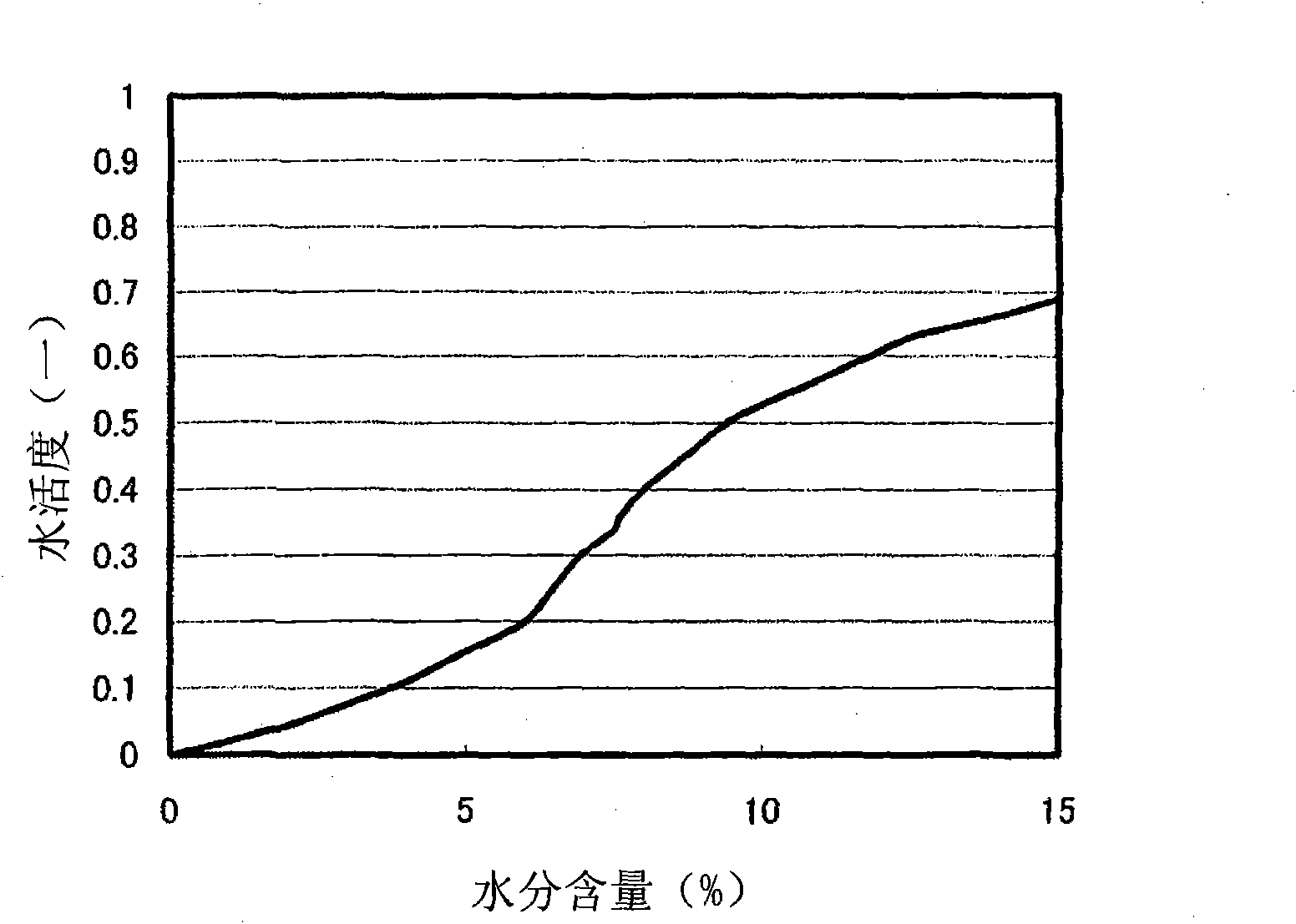

[0249] Next, the present invention will be described in detail based on examples, but the present invention is not limited by these examples. In addition, the numerical value in an Example means a weight part, and "%" means a weight%. In addition, for the measurement of the water activity, "LabMASTER-aw BASIC" (trade name) of a water activity thermostatic measuring device of Novasina Co., Ltd. was used.

[0250] (Chocolate base 1~3 production)

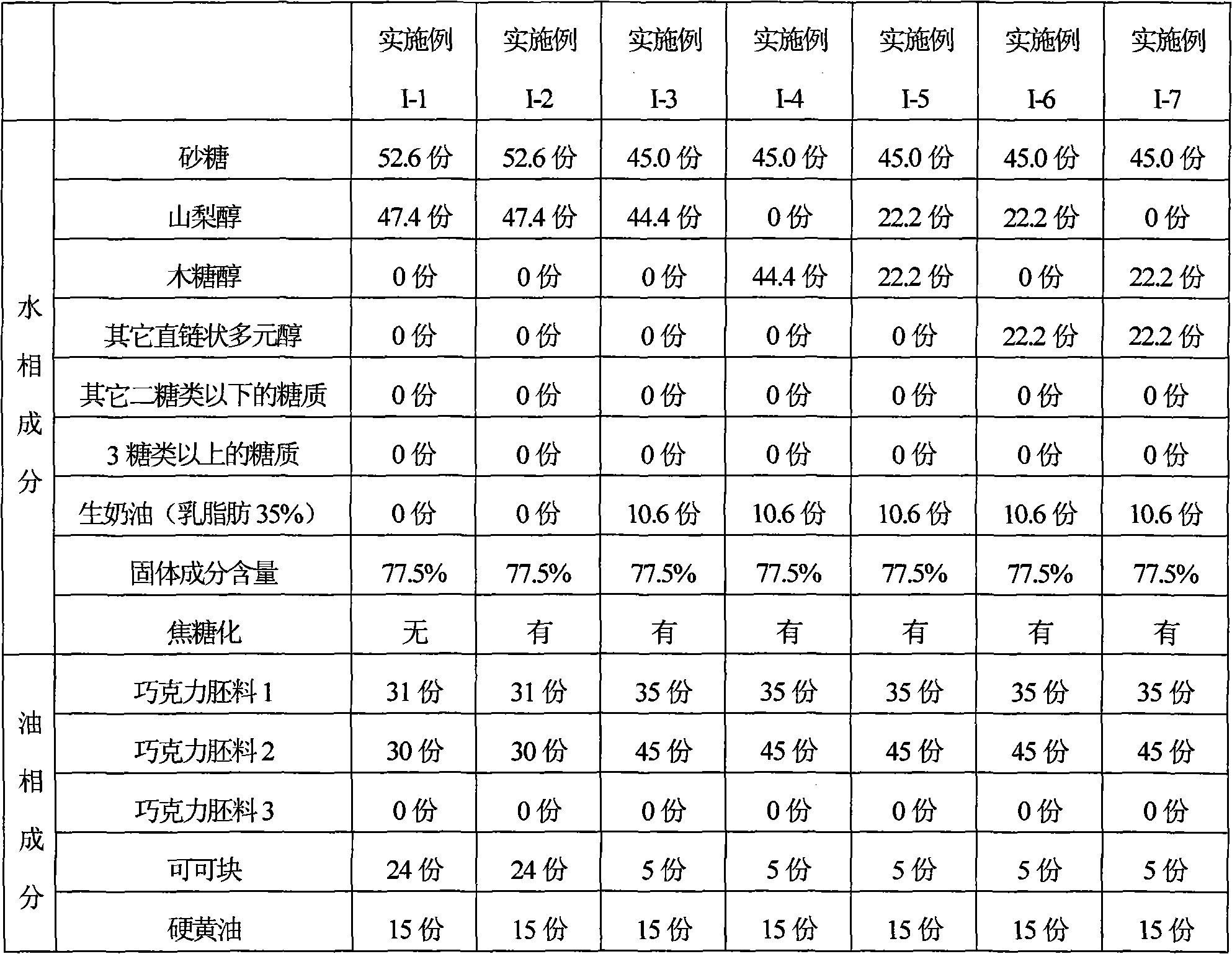

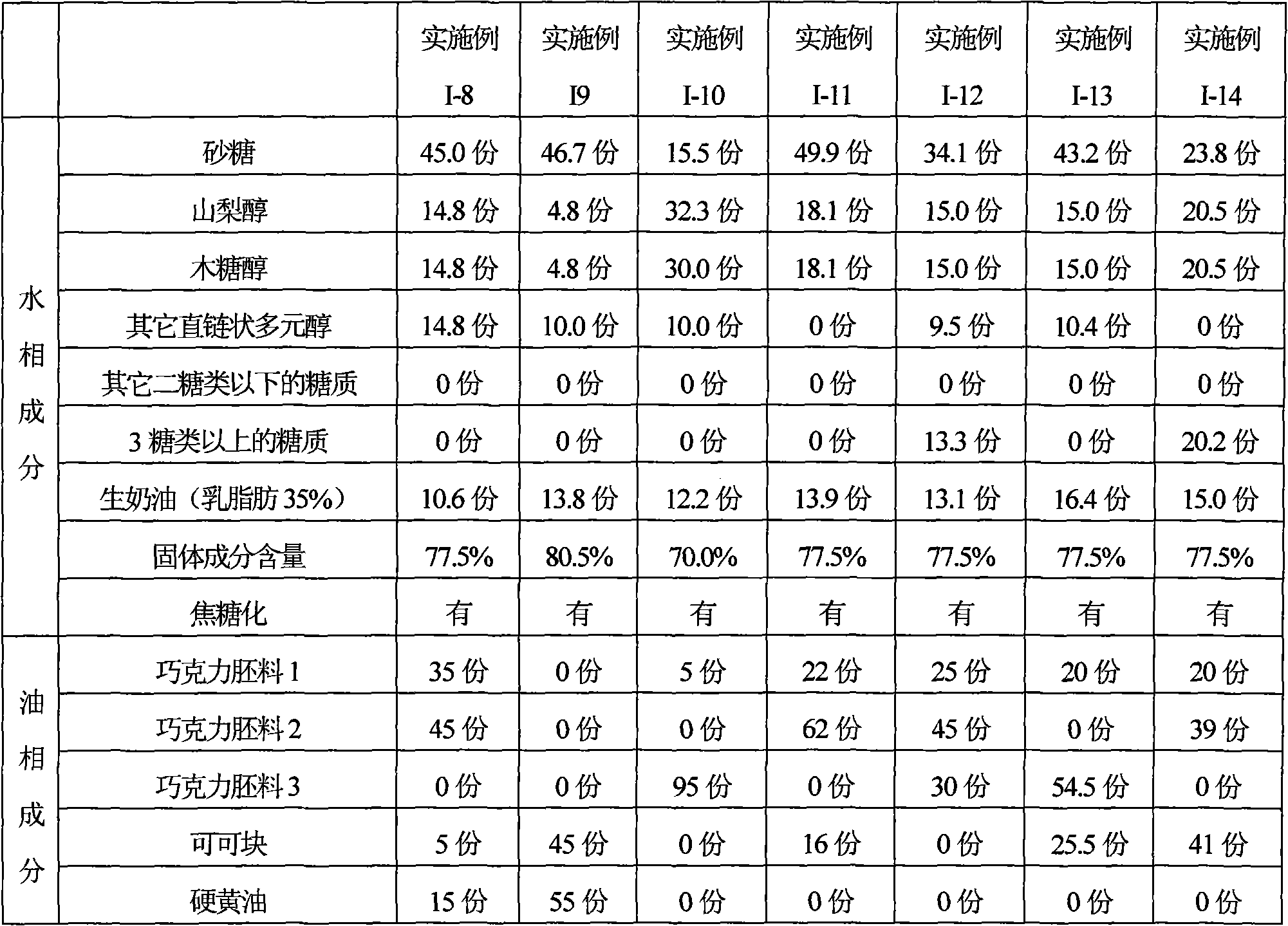

[0251] According to the combination shown in Table I-1, coiling and kneading were carried out to obtain chocolate blanks 1-3.

[0252] Table I-1

[0253]

granulated sugar

Scotch Powder

Scotch block

chocolate base 1

39 copies

24 copies

24 copies

12 copies

1 copy

Chocolate base 2

43 copies

12 copies

0 copies

45 copies

0 copies

chocolate base 3

61.5 copies

16.3 copies

0 copies

22.2 parts

0 copies

...

Embodiment II-1~II-3、 comparative example II-1、II-2

[0296] Embodiment II-1~II-3, comparative example II-1, II-2 (making of composite confectionery)

[0297] As a filling, 1.2 g of the raw chocolate-like composition obtained in Example I-3, Example I-9, or Example I-14 is sandwiched between two of the above-mentioned baked snacks, thereby joining the baked snack and the raw chocolate-like composition thing, obtain the composite snack of embodiment II-1, II-2, II-3 as shown in table II-1. The composite confectionery was subjected to a cycle test in which the temperature of 28° C. and 20° C. was alternately exposed every 12 hours. Table II-1 shows the presence or absence of moisture migration and fat migration after 30 cycles. Sensory evaluation was carried out for moisture migration, and evaluation was carried out for fat migration and whitening of the surface of the baked confectionary and blooming of the chocolate surface. In Comparative Examples II-1 and II-2, a composite confectionery using chocolate base 1 shown in Table I-...

Embodiment V-1~V-4

[0379] (Preparation of Examples V-1 to V-4 and Comparative Examples V-1 to V-6)

[0380] Finally, the above-mentioned water-containing chocolates V-1 to V-10 were molded into spheres with a unit weight of 1.5 g, and dried under reduced pressure. "VACUUM OVENSVO-300" (trade name) manufactured by Shimadzu Corporation was used for vacuum drying. As drying conditions, first, the inside of the apparatus was set at 25° C., and water-containing chocolate was charged. Next, the pressure is reduced so that the pressure in the apparatus is in a vacuum state of 100 Torr or less. A vacuum state was formed to puff the water-containing chocolate, the temperature was raised to 40° C., and vacuum drying was carried out for 3 hours to obtain the aerated chocolates of Examples V-1 to V-4 and Comparative Examples V-1 to V-4. The moisture content of any of the above aerated chocolates is lower than 1%.

[0381] After drying, the chocolate as a sample was taken out and cooled, and evaluated for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com