A kind of anti-collapse calcium phosphate bone cement and its preparation method and application

A calcium phosphate bone cement, anti-collapse technology, applied in medical science, prosthesis and other directions, can solve the problems of delaying CPC curing time, hindering CPC hydration speed, hindering bone cement crystallization, etc., to achieve good clinical application effect, good biological Medical properties, the effect of improving anti-collision properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

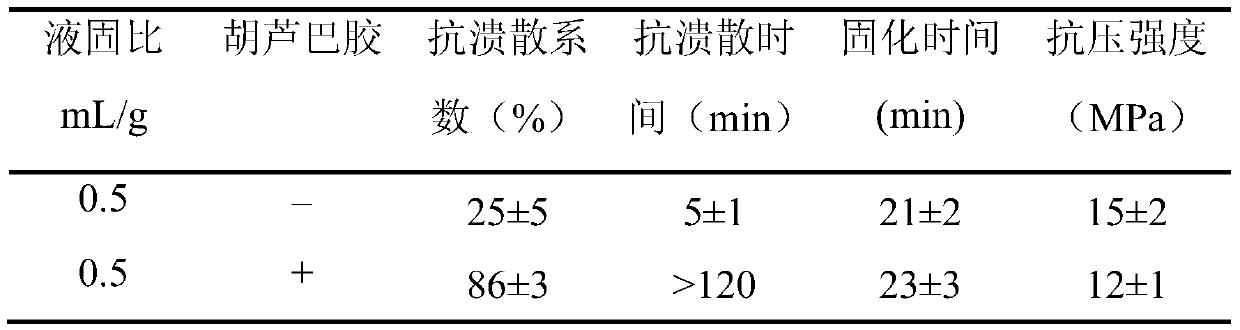

[0026] Fenugreek gum (the mass is 3.0% of the tetracalcium phosphate-calcium hydrogen phosphate bone cement powder) was evenly mixed with the tetracalcium phosphate-calcium hydrogen phosphate bone cement powder. Then, the deionized aqueous solution was uniformly mixed with the calcium phosphate bone cement containing fenugreek gum prepared in this example at a liquid-solid ratio of 0.5mL / g, and the paste was injected into a mold and placed in simulated body fluid at 37°C . The comparison of physical and chemical properties between the anti-collapse calcium phosphate bone cement containing fenugreek gum prepared in this example and the calcium phosphate bone cement without galactomannan vegetable glue is shown in Table 1:

[0027] Table 1

[0028]

[0029] Note: "-" indicates the calcium phosphate bone cement without galactomannan vegetable glue; "+" indicates the calcium phosphate bone cement with galactomannan vegetable glue added, the same as the following table. The co...

Embodiment 2

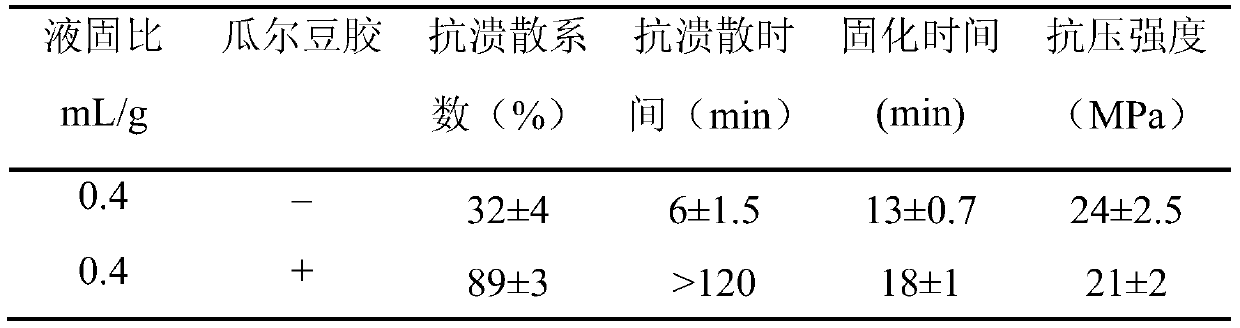

[0032] The guar gum (the mass is 2.0% of the tetracalcium phosphate-β-tricalcium phosphate-dicalcium phosphate bone cement) was evenly mixed with the tetracalcium phosphate-β-tricalcium phosphate-dicalcium phosphate bone cement. Then uniformly mix the 0.125mol / L sodium dihydrogen phosphate solution with the calcium phosphate bone cement containing guar gum prepared in this example according to the liquid-solid ratio of 0.4mL / g, and mix it into a paste and inject it into the mold after forming. In simulated body fluid at 37°C. The comparison of physical and chemical properties between the anti-collapse calcium phosphate bone cement containing guar gum prepared in this example and ordinary calcium phosphate bone cement is shown in Table 2:

[0033] Table 2

[0034]

[0035] Compared with the ordinary calcium phosphate bone cement, the anti-collapse calcium phosphate bone cement containing guar gum prepared in this example has an anti-collapse coefficient of 89±3%, which is m...

Embodiment 3

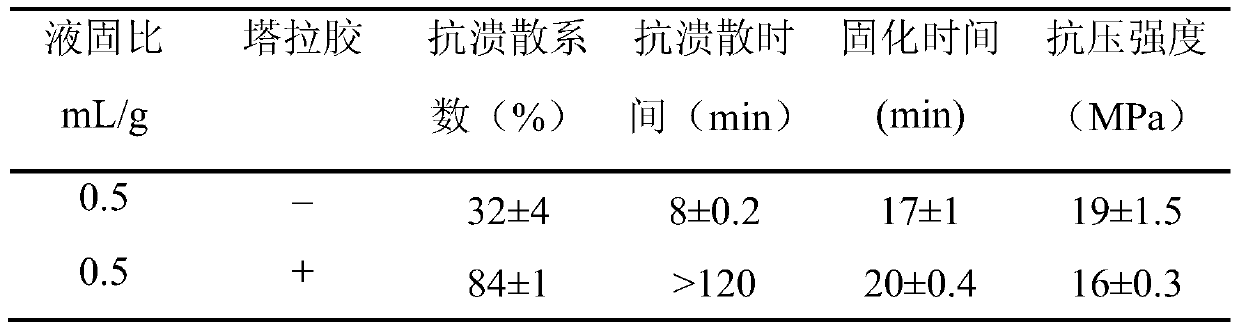

[0037] Tara gum (the mass is 1.0% of α-tricalcium phosphate-calcium hydrogen phosphate-calcium carbonate bone cement) was evenly mixed with α-tricalcium phosphate-calcium hydrogen phosphate-calcium carbonate bone cement. Then uniformly mix the 0.25mol / L sodium hydrogen phosphate buffer solution with the calcium phosphate bone cement containing tara gum prepared in this example according to the liquid-solid ratio of 0.5mL / g, and mix it into a paste and inject it into the mold and place it in the In simulated body fluid at 37°C. The comparison of physical and chemical properties between the anti-collapse calcium phosphate bone cement containing tara gum prepared in this example and ordinary calcium phosphate bone cement is shown in Table 3:

[0038] table 3

[0039]

[0040]Compared with ordinary calcium phosphate bone cement, the anti-collapse calcium phosphate bone cement containing tara gum prepared in this example has an anti-collapse coefficient of 84 ± 1%, which is mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com