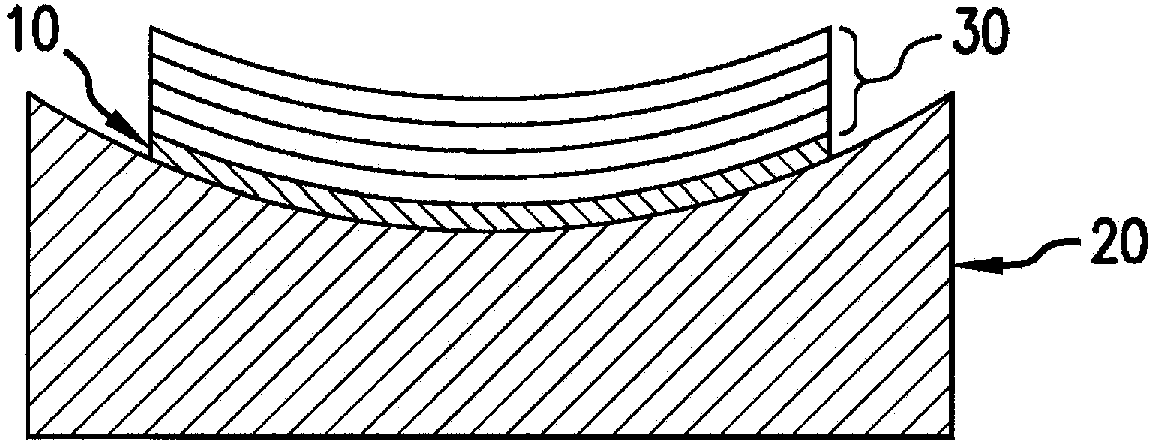

Surfacing film for composite structures and method of making the same

A composite structure and surface film technology, applied in chemical instruments and methods, synthetic resin layered products, novolac epoxy resin adhesives, etc., can solve problems such as trouble, surface film expansion, bubbling repainting process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0055] The following examples are intended to give specific examples of surface films formed according to the present invention, but are not intended to limit the scope of the present invention in any way.

[0056] Nine surface film samples were prepared according to the formulations (1-9) shown in Table 2. All amounts are expressed in percent by weight.

[0057] Table 2

[0058]

[0059]

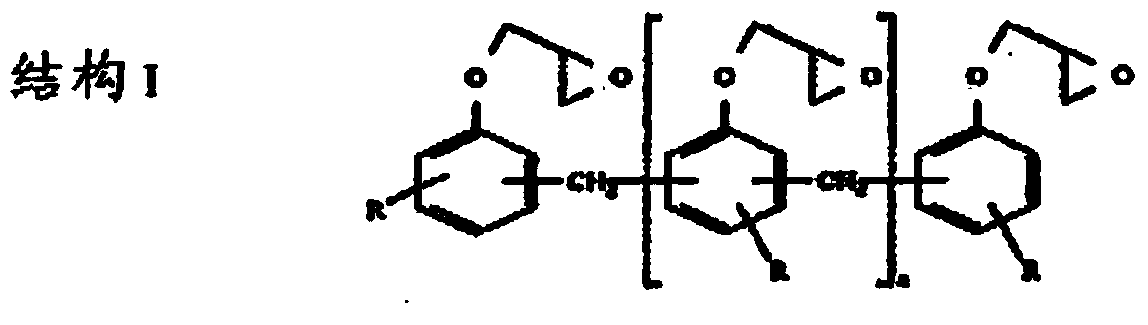

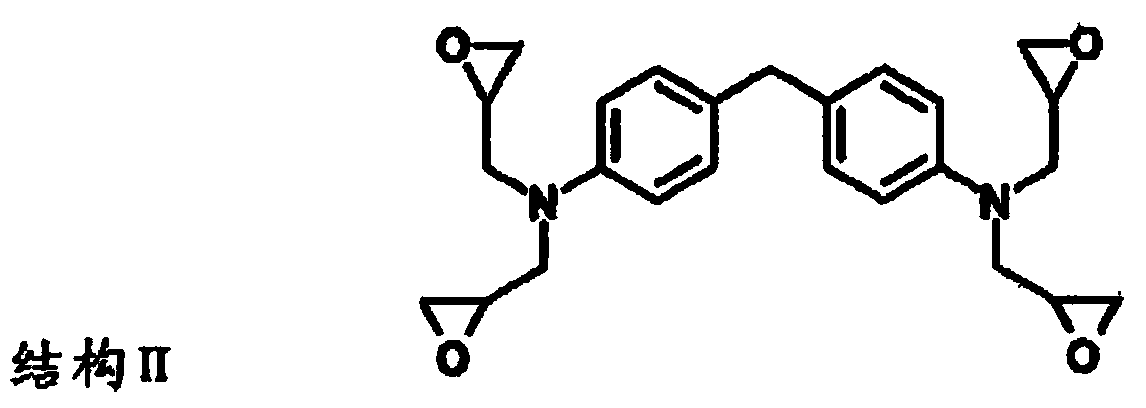

[0060] Each surface film was prepared by adding the components disclosed in Table 2 to a mixing vessel and mixing the components using a high shear laboratory mixer. Add the epoxy first. MEK was added as a solvent to the epoxy resin mixture as necessary to adjust the rheology and solids content of the composition. Subsequently, a toughening agent (pre-reacted adduct and / or PES-PEES copolymer) is added to the epoxy resin. In some surface films (Formulations 4 and 5), a conductive additive (silver flakes or Ag-Cu flakes) was also added to the mixing vessel. Ceramic microspheres, fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com