Paint stripper

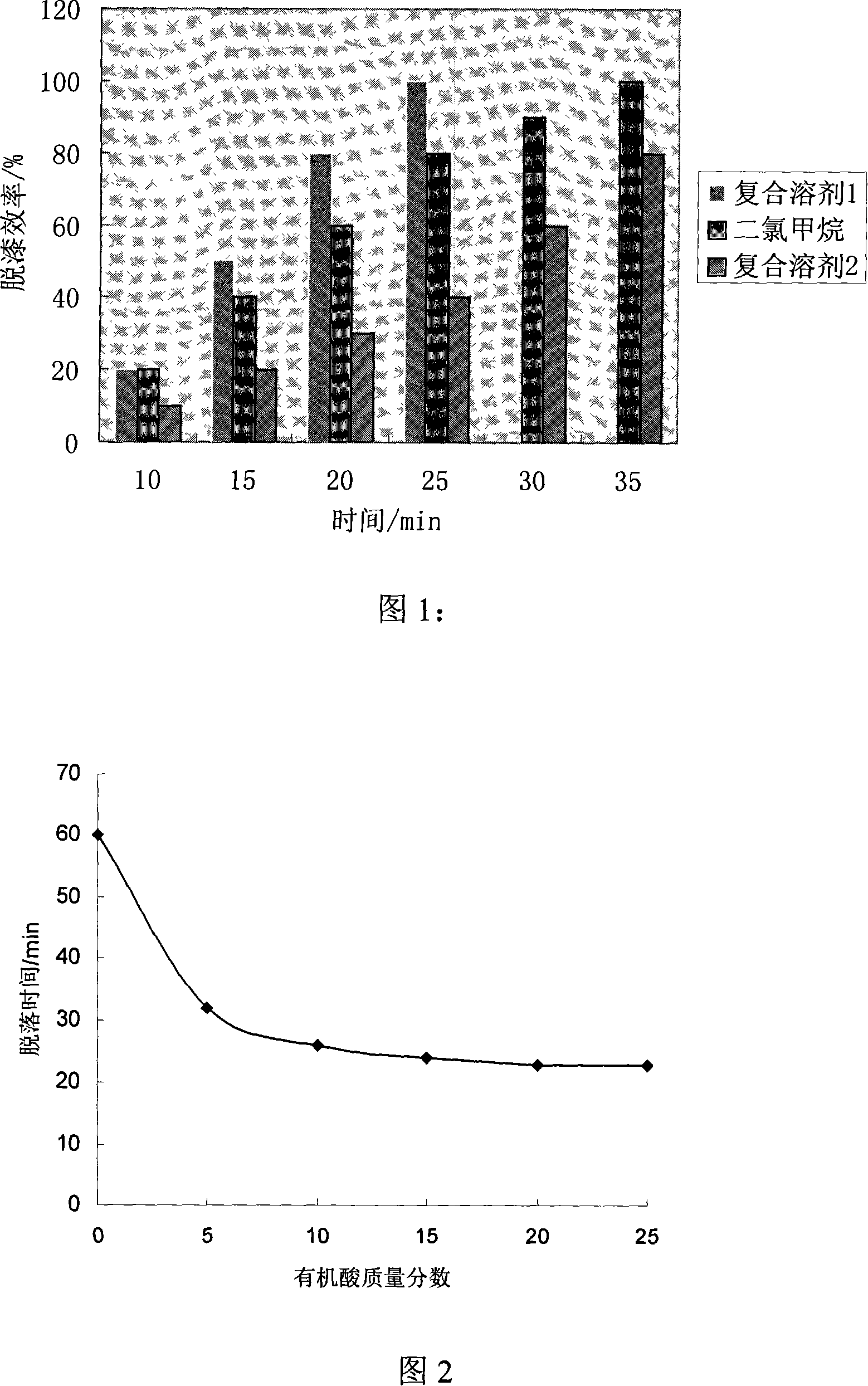

A paint remover and main solvent technology, applied in the direction of chemical paint/ink remover, coating, etc., to achieve the effect of high paint removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] 1. Preparation and application of paint remover:

[0041] 1. Preparation or weighing:

[0042] Prepare or weigh the following components: (1) Component A: halogenated alkanes, such as dichloromethane, 1,2-dichloroethane, n-bromopropane; (2) Component B: cosolvent, such as ethanol; ( 3) Component C: an acidic component, which may be a mixed acid; (4) Component D: a thickener, such as cellulose or its derivatives.

[0043] Then, accurately measure components A, B, and C in a 500ml three-necked flask according to the preparation ratio, stir well with an electromagnetic stirrer, add component D, stir vigorously until uniform, and obtain the finished product, which is sealed and stored.

[0044] 2. The application process of paint remover:

[0045] Wash the paint film; dry the paint film with a cloth; draw 1cm with a compass 2 The circle; apply the quantitative paint remover to the circle; record the time and phenomenon of paint removal.

[0046] 2. Test method:

[0047...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com