Basic paint remover and preparation method thereof

A paint stripper and alkaline technology, applied in the field of paint strippers and alkaline paint strippers, can solve the problems of high toxicity and long paint stripping time of organic paint strippers, and achieve the effect of improving paint stripping activity and weakening corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

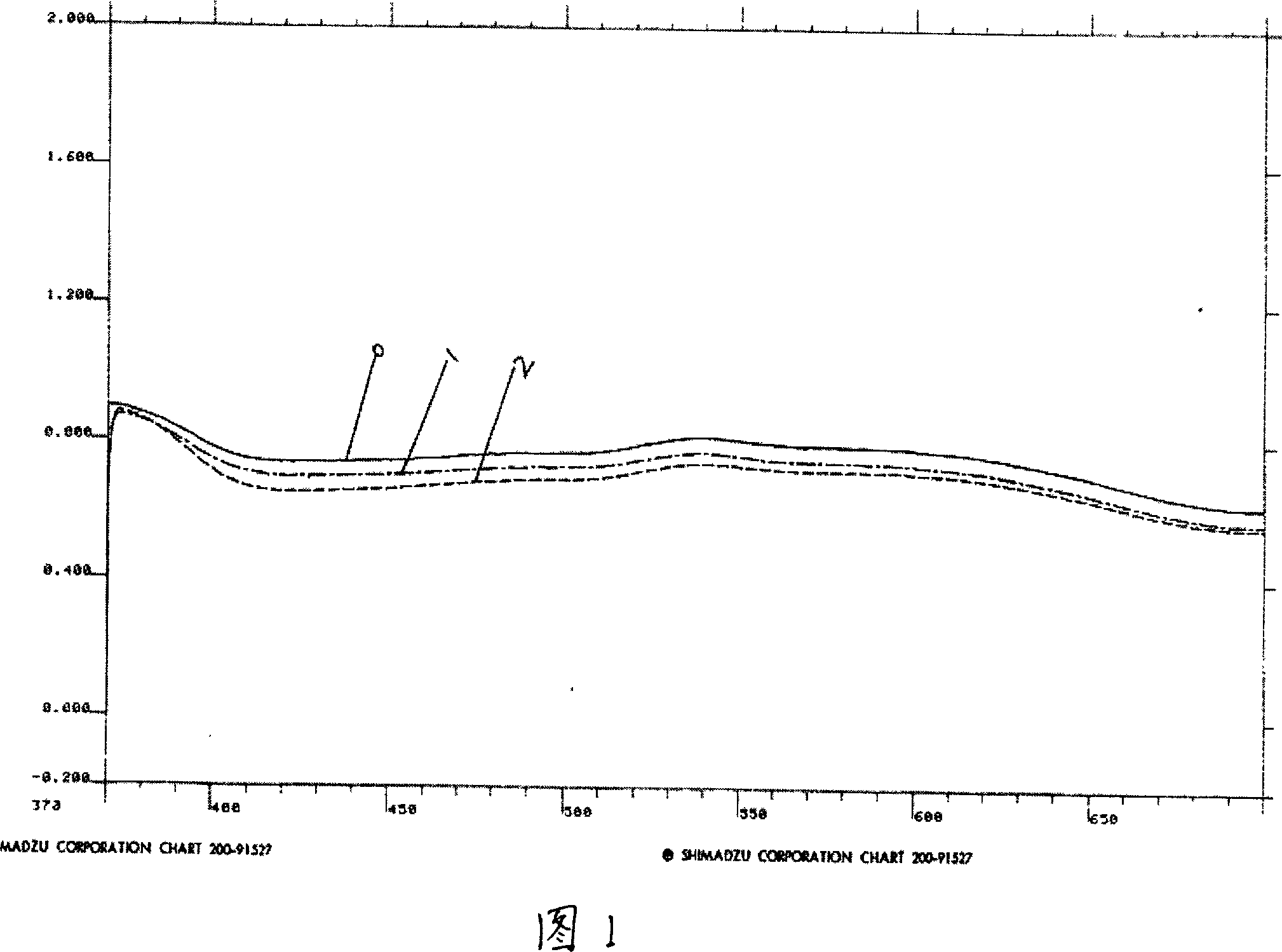

Image

Examples

Embodiment 1

[0020] Add 3.56 grams of potassium hydroxide to 95.45 grams of benzyl alcohol. After the potassium hydroxide is completely dissolved, add 0.868 grams of caprylic acid glyceride and 0.027 grams of 8-mercaptoquinoline, and stir evenly to obtain a paint remover solution. Under the condition of 80°C, the device to be stripped is completely immersed in the solution for 10 minutes of stripping treatment, and the stripping rate can be 100%.

Embodiment 2

[0022] Add 3.62 grams of potassium hydroxide to 94.6 grams of benzyl alcohol. After the potassium hydroxide is completely dissolved, add 1.72 grams of glyceryl caprylate and 0.054 grams of 2,2-dithio-5-nitrobenzoic acid, and stir Uniform paint remover solution. Under the condition of 82° C., the device to be stripped is completely immersed in the solution for 9 minutes of stripping treatment, and the stripping rate reaches 100%.

Embodiment 3

[0024] Add 3.62 grams of potassium hydroxide to 94.6 grams of benzyl alcohol. After the potassium hydroxide is completely dissolved, add 1.72 grams of triglyceride caprate and 0.054 grams of 2,2-dithio-5-nitrobenzoic acid, and stir Uniform paint remover solution. Under the condition of 75° C., the device to be stripped is completely immersed in the solution for 12 minutes of stripping treatment, and the stripping rate reaches 100%.

[0025] The test results show that the paint stripping activity of the above three embodiments is relatively high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com