Ethylene glycol tertiary butyl ether and production technology thereof

A technology of ethylene glycol tert-butyl ether and alcohol tert-butyl ether, which is applied in the field of chemical product process production, can solve problems such as oversupply, and achieve low photochemical reactivity, low toxicity, and mild skin irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below with reference to specific embodiments.

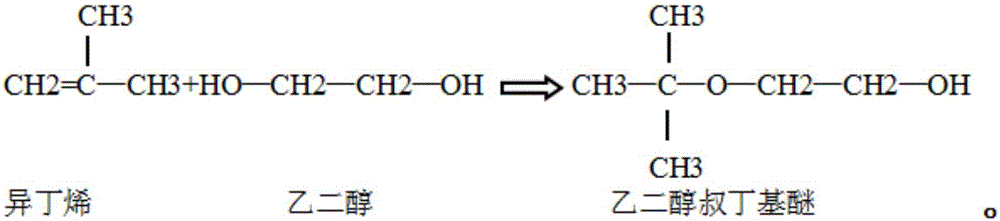

[0053] The ethylene glycol tert-butyl ether described in the present invention is produced by the reaction of isobutylene and ethylene glycol in the mixed C4 under the action of a solid catalyst, wherein the reaction ratio of isobutylene and ethylene glycol is 3-4:0.8- 1.2. As a preferred solution, the reaction ratio of isobutylene and ethylene glycol is 3.7:1; this reaction is a reversible equilibrium exothermic process, and its reaction formula is as follows:

[0054]

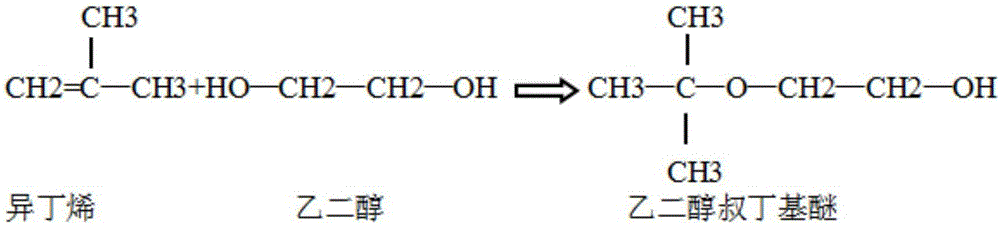

[0055] The selectivity of the reaction is high, and other carbon four components hardly participate in the reaction, but the following side reactions occur at the same time as the main reaction:

[0056]

[0057] The technological process of ethylene glycol tert-butyl ether production technique of the present invention comprises:

[0058] A, reaction unit, comprises the following steps:

[0059] A1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com