Synthetic method of water insoluble polyether synthetic base oil

A technology for synthesizing base oils and synthesis methods, which is applied in the field of synthesis of water-insoluble polyether synthetic base oils, can solve problems such as poor emulsification performance, insufficient compatibility, and insufficient lipophilicity, and achieve good compatibility, Strong lipophilicity and no irritating odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

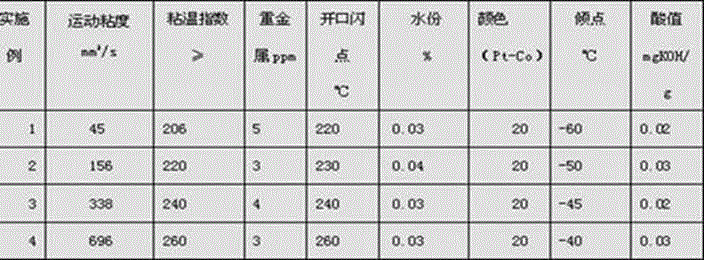

Examples

Embodiment 1

[0027] In the first step, n-butanol is pretreated. In the reaction vessel, put 10-20g 3A molecular sieve per 1kg of n-butanol, stir evenly, let it stand for 24 hours to filter out the molecular sieve, then put in the same fresh molecular sieve, repeat this process three times before use.

[0028] The second step is the preparation of intermediates. Put 2Kg of n-butanol and 1.75g of polymetallic catalyst into the reaction kettle, vacuumize to make the pressure reach -0.092MPa; when the temperature does not exceed 40°C, feed nitrogen into the reaction kettle to raise the pressure to 0.1Mpa, and then Vacuumize to reduce the pressure to -0.092MPa, repeat three times, raise the temperature of the reactor to 120-130°C to initiate the reaction; after the reaction, slowly add 7Kg of propylene oxide to the reactor, control the reaction temperature at 140-160°C No more than 0.2 Mpa, and the reaction time is controlled at 1.5 hours; after the dropwise addition, keep warm for 30 minute...

Embodiment 2

[0031] In the first step, n-butanol is pretreated. In the reaction vessel, put 10-20g 3A molecular sieve per 1kg of n-butanol, stir evenly, let it stand for 24 hours to filter out the molecular sieve, then put in the same fresh molecular sieve, repeat this process three times before use.

[0032] The second step is the preparation of intermediates. Put 2.5Kg of treated n-butanol and 2.2g of polymetallic catalyst into the reactor, vacuumize to make the pressure reach -0.092MPa; when the temperature does not exceed 40°C, feed nitrogen into the reactor to raise the pressure to 0.1Mpa, Vacuum again to reduce the pressure to -0.092MPa, repeat three times, raise the temperature of the reactor to 120-130°C to initiate the reaction; after the reaction, slowly add 7.5Kg of propylene oxide to the reactor, and control the reaction temperature at 140-160°C , the pressure does not exceed 0.2 Mpa, and the reaction time is controlled at 1.5 hours; after the dropwise addition, keep warm for ...

Embodiment 3

[0035] In the first step, n-butanol is pretreated. In the reaction vessel, put 10-20g 3A molecular sieve per 1kg of n-butanol, stir evenly, let it stand for 24 hours to filter out the molecular sieve, then put in the same fresh molecular sieve, repeat this process three times before use.

[0036] The second step is the preparation of intermediates. Put 3Kg of treated n-butanol and 3.0g of polymetallic catalyst into the reactor, vacuumize to make the pressure reach -0.092MPa; when the temperature does not exceed 40°C, feed nitrogen into the reactor to raise the pressure to 0.1Mpa, and then Vacuumize to reduce the pressure to -0.092MPa, repeat three times, raise the temperature of the reactor to 120-130°C to initiate the reaction; after the reaction, slowly add 9Kg propylene oxide to the reactor, control the reaction temperature at 140-160°C, No more than 0.2 Mpa, and the reaction time is controlled at 1.5 hours; after the dropwise addition, keep warm for 30 minutes, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com