Continuous production method of high-purity hydrochloric acid

A production method and technology of high-purity hydrochloric acid, applied in the direction of chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, etc., can solve problems such as inability, failure to meet production requirements, failure to give test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This example provides a method for preparing high-purity hydrochloric acid, which is produced by using the above-mentioned fully enclosed ultra-clean production system, including the following steps carried out sequentially and continuously:

[0054] (1) Put industrial hydrochloric acid into the circulating stirring reaction kettle, add ferrous sulfate whose weight is 0.8% of industrial hydrochloric acid at the same time, and circulate stirring reaction for about 1.5 hours;

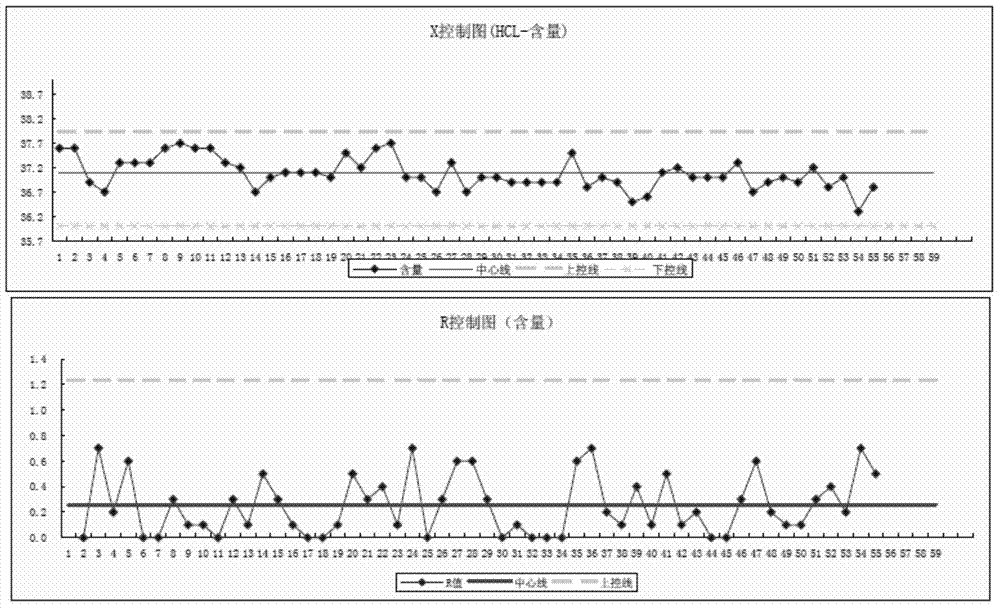

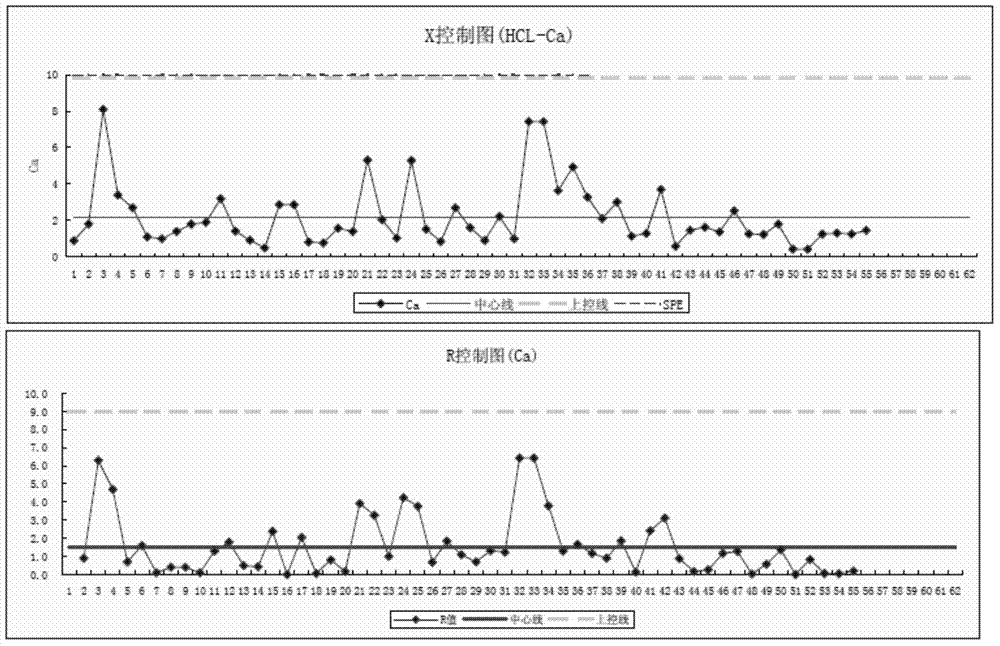

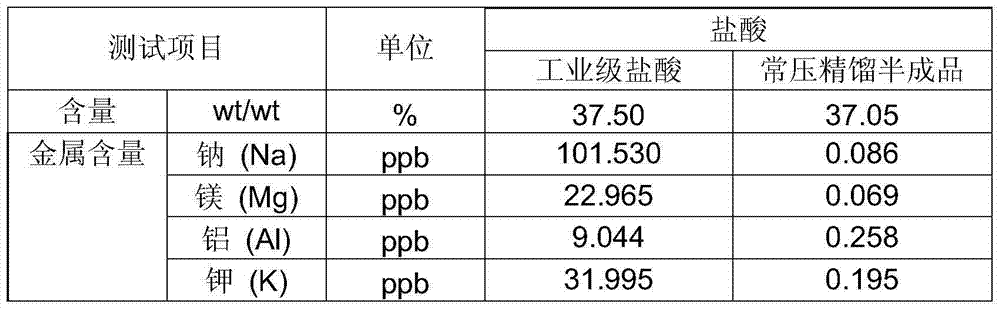

[0055] (2) The hydrochloric acid treated in step (1) is passed into the atmospheric distillation equipment at a flow rate of 500L / H, the heating steam pressure is controlled to be 0.25±0.05Mpa, the reflux ratio is 1:1.2, and the condensed water temperature is 4-8°C. Rectifying, obtains atmospheric distillation semi-finished product, and sampling detection data is as shown in table 1;

[0056] (3) The semi-finished product after step (2) enters the circulating filtration equipment for filtration for...

Embodiment 2

[0065] This example provides a method for preparing high-purity hydrochloric acid, which is basically the same as Example 1, except that the reflux ratio during atmospheric distillation is 1:2. The pressure inside the vacuum distillation kettle is 85KPa, and the reflux ratio of vacuum distillation is 1:2. The detection data of gained hydrochloric acid finished product is as shown in table 3.

Embodiment 3

[0067] This example provides a preparation method of high-purity hydrochloric acid, which is basically the same as in Example 1, except that the pressure inside the vacuum rectification tank is 25KPa, and the reflux ratio of vacuum distillation is 1:1.8. The detection data of gained hydrochloric acid finished product is as shown in table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com