Method for purifying organic amine electroplating additive

A technology of electroplating additives and purification methods, applied in the directions of organic chemistry, chemical instruments and methods, preparation of organic compounds, etc., to achieve good adaptability and market prospects, reduced emissions, and reduced costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

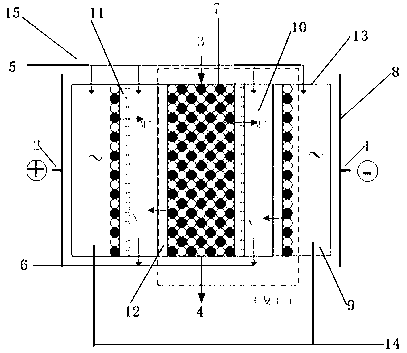

[0039] Take 100kg of industrial-grade TMAH pentahydrate, use ultrapure water to prepare a 25% concentration of TMAH solution, use a microfiltration membrane with a pore size of 2 μm to filter the solution to obtain a clear and transparent liquid, put the filtrate into a PP material storage tank, and use a raw material pump 21 The TMAH is input into the electrodeionization device 15, and the purification chamber 7 is equipped with a commercial brand D261 strong basic styrene-based anion exchange resin and Amberlite252Na strong acidic styrene-based cation exchange resin, and the ratio of the anion and cation exchange resins is 2:3 (V: V), cation exchange membrane 11 and anion exchange membrane 12 are polyethylene sulfonic acid type cation membrane 3361W polyethylene tertiary ammonia type anion membrane 3362W (Shanghai Chemical Water Treatment Plant), turn on the DC power supply, operate at constant voltage, and set the initial voltage 70V, conduct electrodeionization operation, c...

Embodiment 2

[0041] Process conditions and equipment are the same as in Example 1, except that the cation-exchange membrane 11 and anion-exchange membrane 12 in the EDI device 15 are changed into ethylene-propylene rubber homogeneous cationic membrane KM ethylene-propylene rubber homogeneous anion membrane AM (Shandong Tianwei membrane Co., Ltd.), when the EDI operation reaches 60 minutes, the anion and cation concentration of the sample is monitored and meets the SEMI standard. As shown in Table 2, the concentration of all metal ions is lower than 2-10ppb, the concentration of chloride ion is lower than 0.1ppm, and the concentration of carbonate Ions below 100ppm. The concentration of TMAH obtained by acid-base titration is 21.67%. Without considering other factors such as electrolytic separation of water, the recovery rate of TMAH can reach 86.7%.

Embodiment 3

[0043] Process condition and equipment are the same as embodiment 2, the difference is that the ion exchange resin in the EDI unit 15 uses JK204 strong base gel type anion exchange resin and D001 macroporous strongly acidic styrene cation exchange resin to be packed in the mixed bed mode instead Purification chamber 7, the ratio of anion exchange resin and cation exchange resin in purification chamber 7 is 2:3 (V:V). When the reaction reaches 60min, take a sample for inspection. After testing, as shown in Table 2, after concentration conversion, all metal ion concentrations are lower than 2-10ppb, chloride ion concentrations are lower than 0.1ppm, and carbonate ions are lower than 100ppm. SEMI standard. The concentration of TMAH at this time was determined to be 21.34% by acid-base titration. Without considering other factors such as electrolytic separation of water, the recovery rate of TMAH was calculated to reach 85.4%.

[0044] From the results of the above examples, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com